Absoger

Cooling and CA , Measurements

Advantages of the controlled atmosphere for the preservation and transport of high quality berries

The Palicontrol system and the Absoger gaseous shock treatment enable high quality berries to be marketed for a longer time

Within the berry production chain, the postharvest stage is essential in order to achieve consumer needs. Quality is defined by a number of parameters such as color, firmness, size, lack of damage and pathologies, sweetness/acidity balance and flavor.

Strawberries can be stored for 7 days and blueberries for up to 14 days with proper harvest management, fast cooling and storage at 0ºC and relative humidity of 90-95%.

In order to extend this conservation, ABSOGER, a leading company in the controlled atmosphere (CA) industry for more than 30 years, has developed a range of solutions to obtain high quality berries without chemicals:

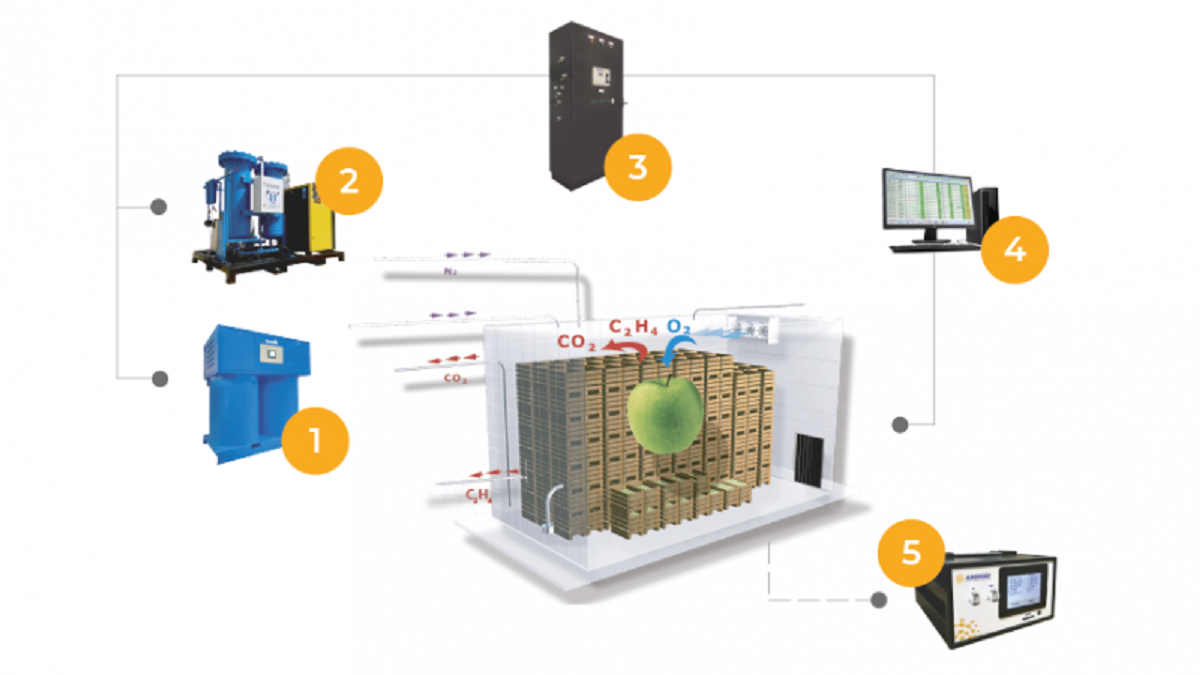

Palicontrol, modular controlled atmosphere system

The Palicontrol system is a tool for preserving berries and other high value-added fruits in CA, by reducing their metabolic activity, dehydration and stopping fungal development (mainly Botrytis cinerea).

In this way, a better quality is achieved for a longer duration, widening the commercial window and thus favouring the choice of the right time to market.

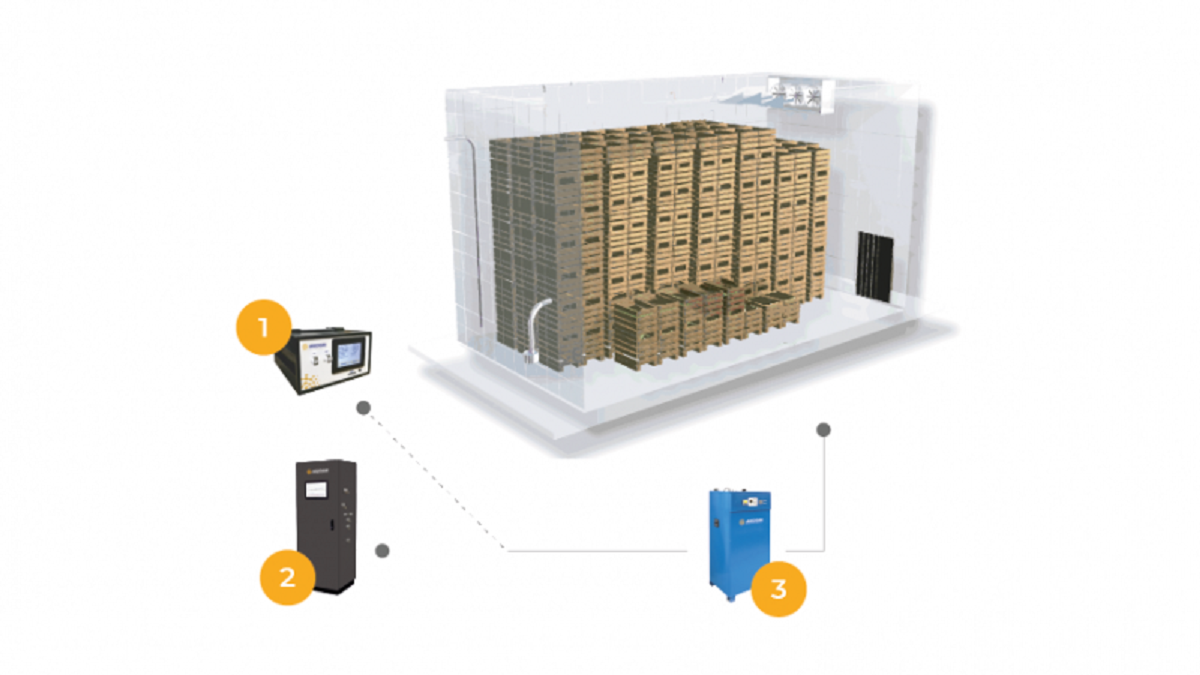

Gaseous shock to prevent fungi growth during transportation

Gaseous shock treatment involves exposing the berries to an atmosphere rich in CO2 and O3, without requiring bags or other materials.

Thus, the fruit is disinfected and cured, preventing the development of microorganisms during transportation and extending the shelf-life of the fruit, by preserving its firmness and flavor.

With this information, Absoger takes part in the book "Cultivo, poscosecha, procesado y comercialización de berries".