Absoger

Cooling and CA , Measurements

System for Dynamic Pressure Management in Controlled Atmosphere Chambers

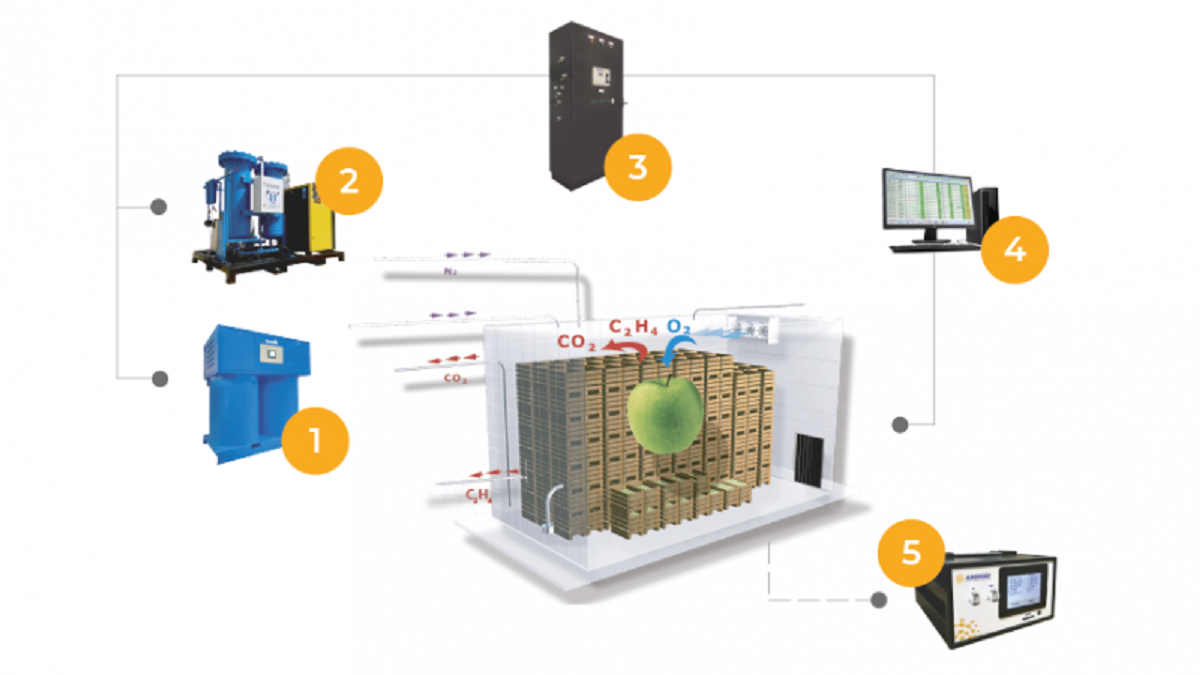

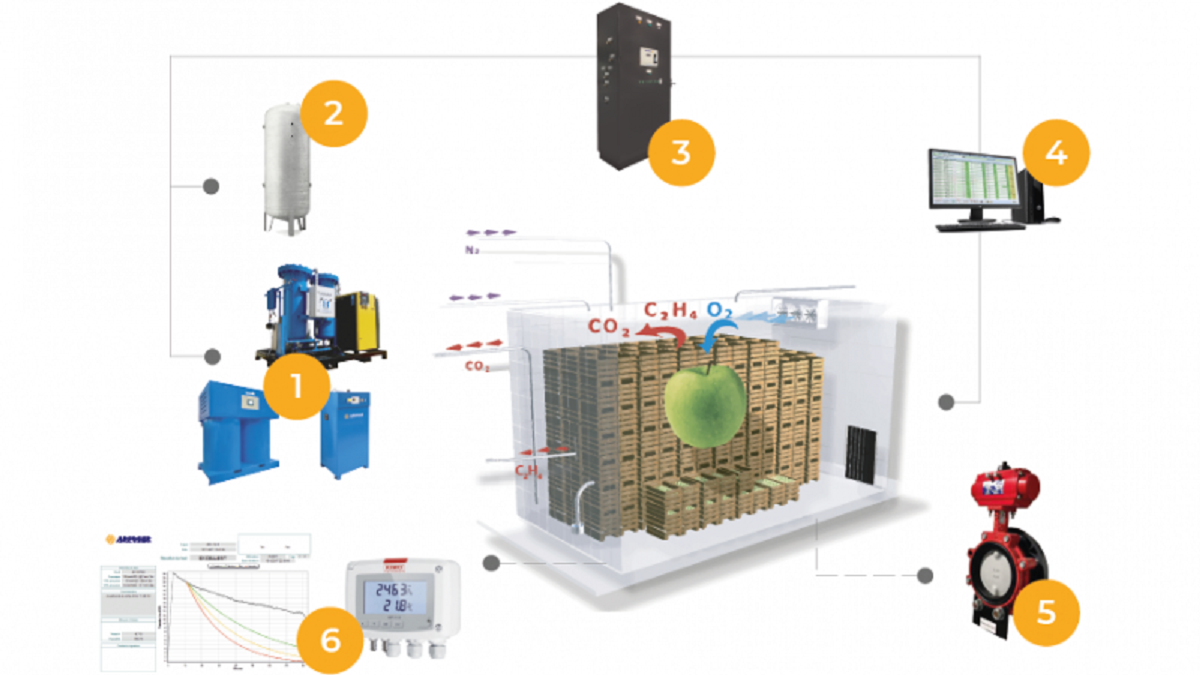

ABSOGER's Dynamic Pressure Management system compensates for pressure changes inside the controlled atmosphere chambers related to the operation of the refrigeration system, as well as to mitigate sealing defects that prevent storage with very low oxygen values (XLO).

Through a nitrogen injection and automatic evacuation, a stable pressure is maintained which prevents oxygen ingress.

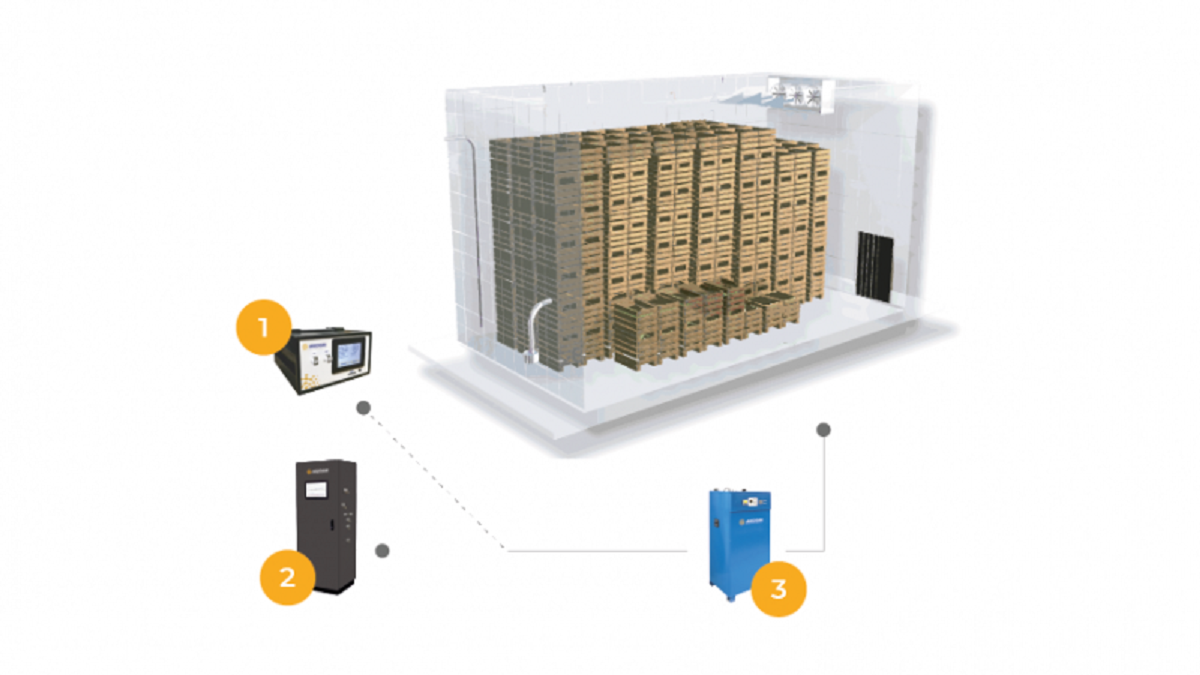

Equipment:

- Equipment and AC-system for nitrogen generation and gas control

- Nitrogen storage tank and parallel nitrogen distribution network with auto-injection

- Electromechanical automatic gas management system with pressure control

- Computer supervision with remote control via PC or Smartphone

- Solenoid valve for automatic pressure regulation inside the chamber

- High quality pressure sensor with real time measurement and auto calibration.

Benefits:

- Conservation in XLO possible in all types of chambers (panel, brick, concrete) new or existing

- Energy savings (>25%): less nitrogen consumption, less use of activated carbon and CO2 adsorption equipment

- Improved airtightness: maintains ULO or XLO rates even in old AC chambers with low airtightness levels

- Better preservation quality: less dehydration, stable O2 and CO2 curves

- Possibility to automatically perform leak tests through the supervisor.

Are you interested in this product?

Fill out the form and we will contact you as soon as possible