Absoger

Cooling and CA

The Dynamic Pressure Management System that ensures perfect airtightness in AC chamber

ABSOGER's Dynamic Pressure Management System guarantees optimal storage conditions by maintaining perfect airtightness in the AC chambers

As a French family-owned company with over 40 years of expertise in manufacturing-controlled atmosphere equipment, ABSOGER is committed to providing innovative solutions that enhance fruit preservation conditions in cold stores.

Here is an in-depth look at our Dynamic Pressure Management System.

Dynamic Pressure Management System

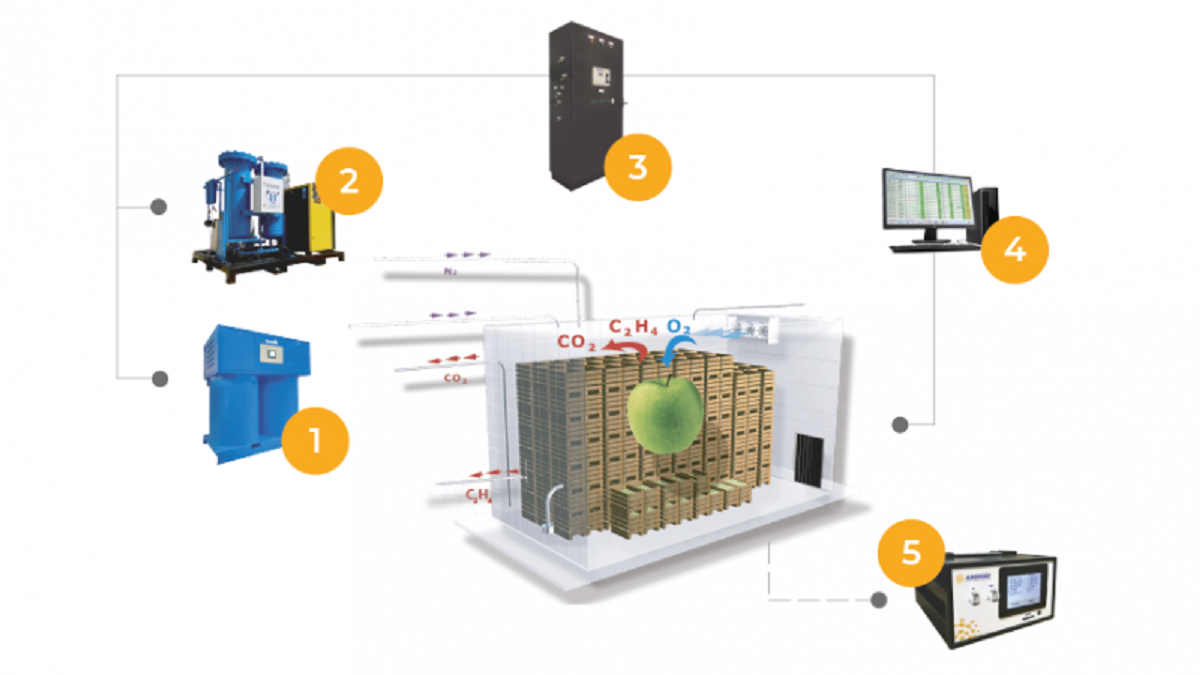

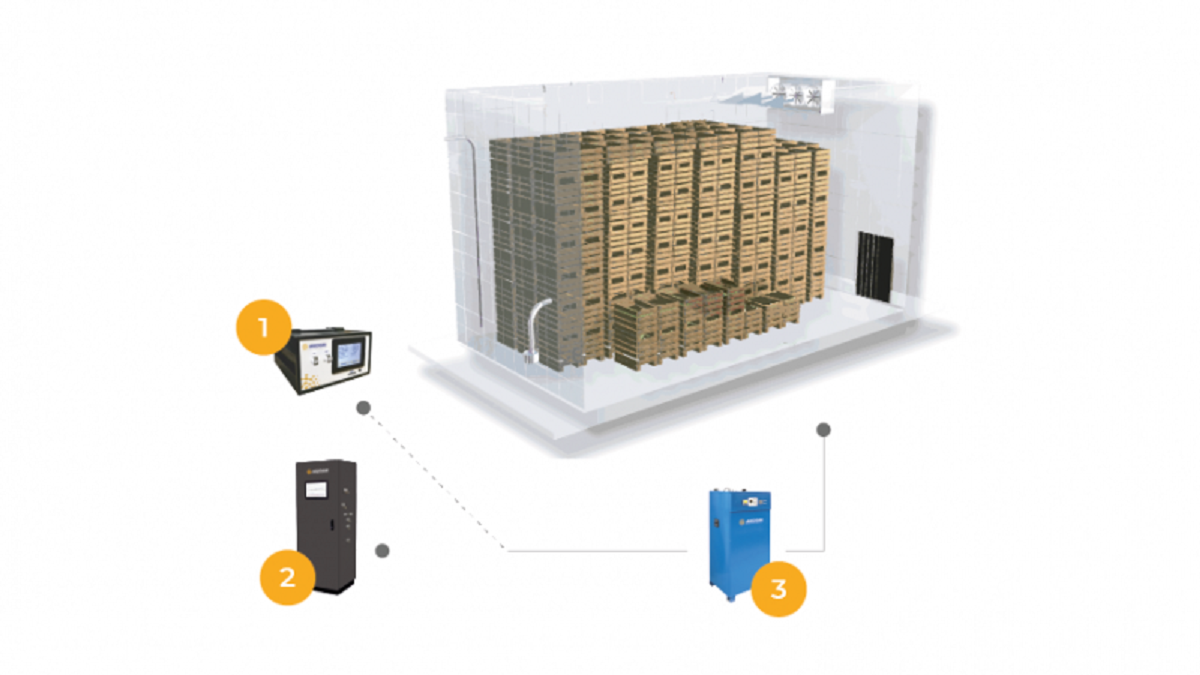

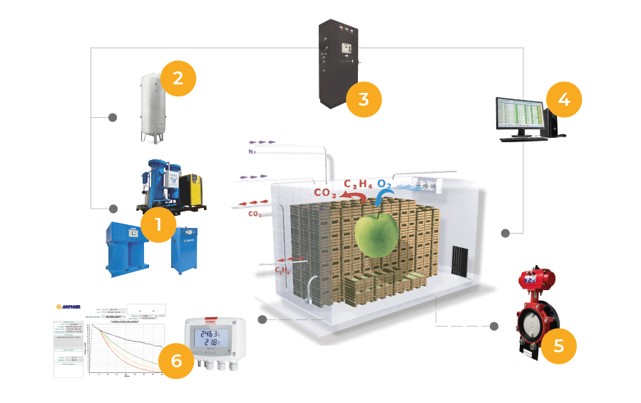

Our Dynamic Pressure Management System ensures optimal storage conditions by maintaining perfect airtightness in controlled atmosphere (CA) chambers. Automatic pressure regulation keeps a slight overpressure inside the chamber through automatic micro-injections of nitrogen, preventing oxygen ingress, which can compromise the storage environment. This dynamic management reduces the need for constant nitrogen supply and decreases the operating time of nitrogen generators and CO2 absorbers, leading to substantial energy savings. Additionally, the system is capable of maintaining low oxygen levels (<1%) even in older, less airtight chambers without the need for frequent regeneration of the CO2 absorber's activated carbon. Consistent levels of O2 and CO2 throughout the storage period improve the quality of stored produce by minimizing dehydration and maintaining better overall quality. Our system includes a feature for automatic airtightness testing of CA chambers, allowing users to monitor and maintain the integrity of their storage environment effortlessly.

Advanced Atmospheric Control Technologies

In line with our commitment to advanced controlled atmosphere in cold storage solutions, ABSOGER focuses on Extreme Low Oxygen (XLO) and ethylene control technologies. By maintaining extremely low oxygen levels (between 0.5% and 1%) and controlling ethylene production, our system reduces the need for 1-MCP treatments or complements them when they cannot be used. Lower ethylene levels help extend the shelf life of fruits by reducing the risk of disorders such as scald.

ABSOGER's system is built around several core components that ensure seamless integration and operation. The nitrogen generator provides a reliable supply of nitrogen for maintaining low oxygen levels. Dedicated software allows precise control and monitoring of storage conditions. Pressure sensors and regulation valves ensure accurate pressure adjustments, while safety valves guarantee safe operation by preventing overpressure situations.

Commitment and Global Network

ABSOGER's innovations are rooted in our dedication to advancing controlled atmosphere technology. We strive to offer solutions that not only meet but exceed the expectations of our customers worldwide. Our technology is designed to be adaptable to various types of storage chambers, including those constructed from different materials like polystyrene, polyurethane, and block paneling.

With installations across five continents and a robust network of local installers, ABSOGER ensures that our customers receive top-notch support and service. In Spain, for example, we collaborate with TIM Fred to provide local technical support and installation services.