AgroFresh

Measurements

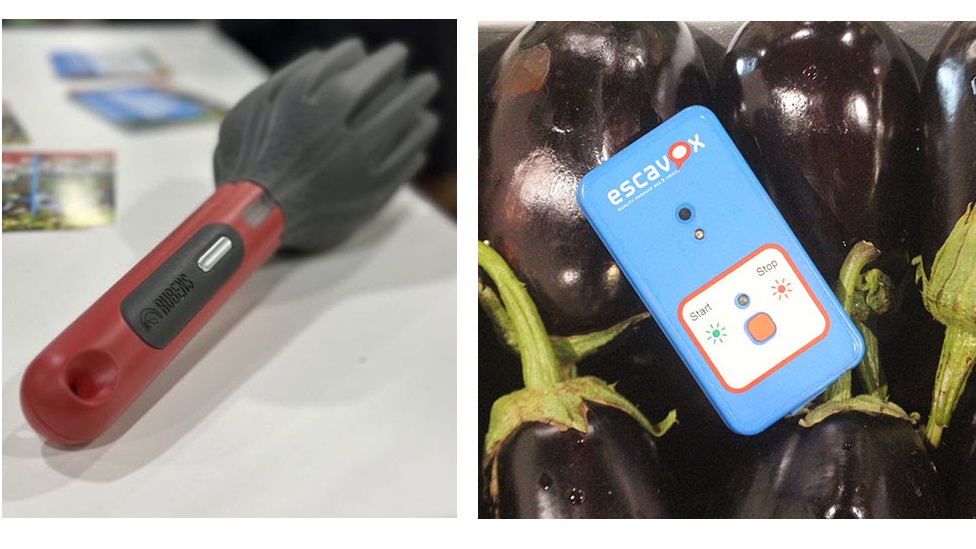

Rubens Technologies and FreshCloud: A Boost to Efficiency and Accuracy in the Fresh Produce Value Chain

The portable spectral scanner from Rubens Technologies, integrated with the FreshCloud platform, optimizes the quality assessment of fresh produce, enhancing efficiency, accuracy, and reducing waste in the value chain

The assessment of fresh produce quality is a crucial process to ensure its suitability for consumption. However, traditional sampling techniques are often labor-intensive, time-consuming, and generate a high volume of waste. The portable spectral scanner from Rubens Technologies has revolutionized this practice, offering a fast, precise, and non-invasive solution. This device collects key data without damaging the product or generating waste, significantly optimizing harvesting and sorting processes within the global supply chain. Additionally, its integration with AgroFresh’s FreshCloud platform takes efficiency and accuracy in fresh produce management to unprecedented levels.

Non-Destructive Quality Assessment

The Rubens Technologies scanner stands out for its ability to assess fruit quality without causing any damage. Its operation is simple and efficient: by placing the fruit inside the device’s hood, scanning begins automatically at the press of a button. The scanner’s connected application communicates with a server that processes the data in real time, providing accurate information on the fruit’s condition within seconds.

Among the key indicators the scanner can measure are ºBrix (total soluble solids), starch, and firmness. These parameters are gathered from the fruit’s surface without requiring invasive testing, which not only enhances efficiency but also reduces product waste.

Efficiency and Waste Reduction

By working with a larger sample size, the scanner improves the accuracy of quality assessments, ensuring that only the best-quality fruit reaches the market, thereby preventing waste. Automating the data collection process significantly reduces costs associated with testing and sorting, benefiting both producers and end consumers.

Greater Measurement Accuracy

What truly sets this solution apart from other technologies on the market is its deep learning-based calibration model. Using neural networks developed in the backend, the system achieves exceptional accuracy in measuring parameters such as ºBrix content, firmness, and starch. This technology not only optimizes the measurement process but also ensures that the data obtained is as precise as possible, facilitating strategic decision-making based on reliable information.

Connection with FreshCloud: A Promising Future

The impact of this innovation extends beyond data collection. By integrating the scanner with AgroFresh’s FreshCloud platform, the collected data is digitized and processed in real time. This allows users to optimally interpret the information and make well-informed decisions regarding harvest timing.

Producers can now more accurately determine the ideal time to harvest and classify fruit, leading to higher profitability and a significant reduction in waste.

A Step Towards Digital Agriculture

The collaboration between Rubens Technologies and AgroFresh Solutions marks a milestone in digital agriculture, combining advanced technology with practical and accessible solutions. The portable scanner not only facilitates precise fruit quality assessment but also provides producers with tools to make more informed and efficient decisions, leading to greater profitability and sustainability for the industry. With the power of artificial intelligence and FreshCloud connectivity, farmers now have a powerful tool that not only enhances the quality of the final product but also optimizes the entire harvesting and sorting process.

In the image, César Balguerias, EMEA Data & Digital Product Lead at AgroFresh, during Fruit Logistica 2025.