News

An Electronic Cherry to Improve Exports and Reduce Economic Losses

Specialists from INTA have developed an innovative prototype that detects impacts during packing and transportation, optimizing the quality of cherries destined for international markets

As of 2024, Argentina has exported 7,210 tons of cherries to destinations such as Europe, the United States, Hong Kong, Singapore, and China, with an average price of $4 per kilogram, according to data from the Argentine Chamber of Integrated Cherry Producers (CAPCI).

To maintain this commercial value and optimize the quality of export cherries, a team from INTA (National Institute of Agricultural Technology) has developed an electronic cherry. This innovative device records the impacts suffered by the fruits during handling, thus improving packing and shipping processes.

Technology to Reduce Fruit Damage

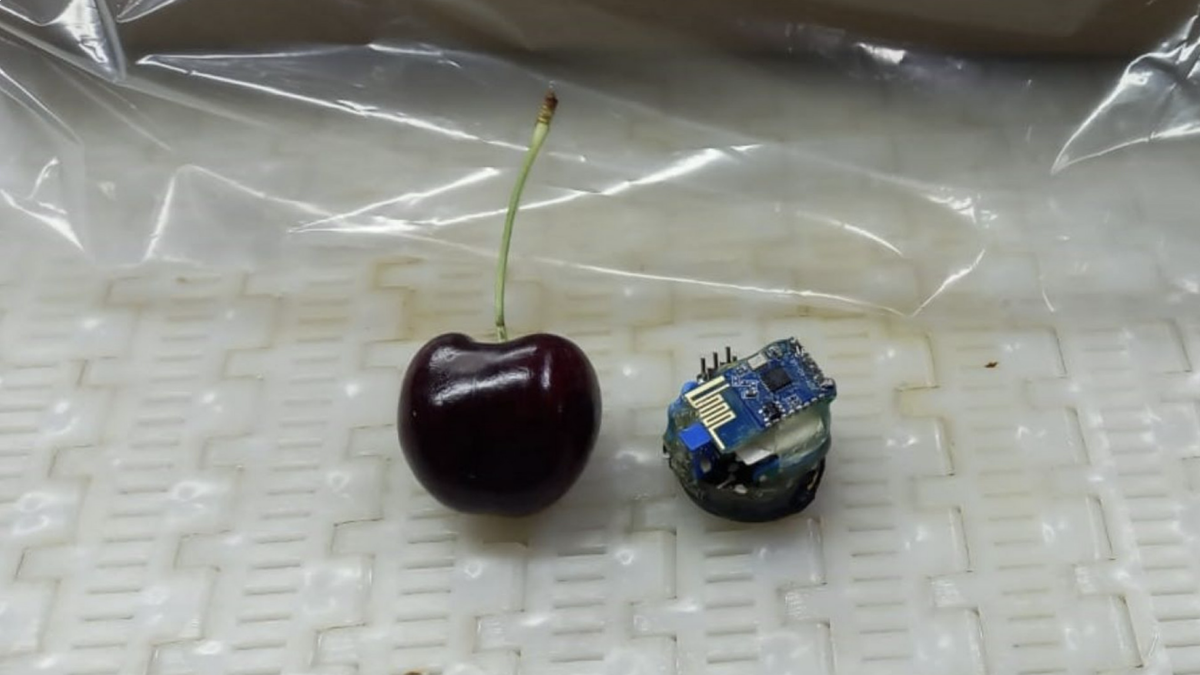

Andrés Moltoni, head of the INTA Agroelectronics Laboratory, explained that this electronic cherry contains sensors that simulate the journey of a real cherry, detecting the impacts the fruits suffer at different stages. The prototype is similar in size, weight, and hardness to the varieties of cherries available on the market, ensuring that the data collected is representative.

During packing and transportation, cherries suffer impacts that can result in superficial damage known as pitting, reducing their commercial value. Moltoni highlighted:

"On average, 5% of cherries are lost due to pitting, but with this technology, a correct decision-making process could reduce losses by 50%, which equates to 2.5% of the total exported, or 180,000 kilos, worth $720,000."

Significant Losses and an Efficient Solution

Liliana San Martino, researcher at INTA Los Antiguos (Santa Cruz), pointed out that pitting losses in packing plants can range from 10% to 40%, according to recent studies. Since cherries are extremely delicate, the damage is not immediately visible but becomes apparent up to three weeks later, at the destination. Therefore, minimizing impacts during the packing process is crucial.

Thanks to this technology, some warehouses have been able to make adjustments to the calibration of their conveyor machines, reducing the recorded impacts. San Martino stated:

"We have been evaluating different cherry varieties for four seasons and adapting the electronics to the needs of the process."

Innovation in a Compact Prototype

The electronic cherry, currently in its second version, features a Bluetooth wireless transmitter that allows it to connect to mobile devices, along with a rechargeable lithium battery. It also includes an improved accelerometer to record impacts with greater accuracy. The prototype's casing has been optimized using 3D printing, testing different materials and thicknesses until the best combination for measurements was found.

Moltoni concluded, highlighting the potential positive impact of this development both in Argentina and in other producing countries like Chile:

"This technology provides key information for packing plants to improve their processes, leading to less waste and greater profits for the sector."