Brimapack

Packaging

Another Automated Iceberg Harvesting Rig for Las Primicias

BrimaPack BV announced that they have commissioned a new Columbia VeTrac e-Drive Harvesting Rig for Las Primicias in Murcia Spain

Ron van de Pavert, BRIMAPACK's CEO, says:

"We are very proud on our Columbia VeTrac e-Drives”

"And the commissioning was like a text book. We started Monday afternoon directly with production. The next day we got stock at our hotel because the town was flooded. We could track the production remotely on our phones. And watch the people of Las Primicias operating everything already by themselves at impressive production numbers.”

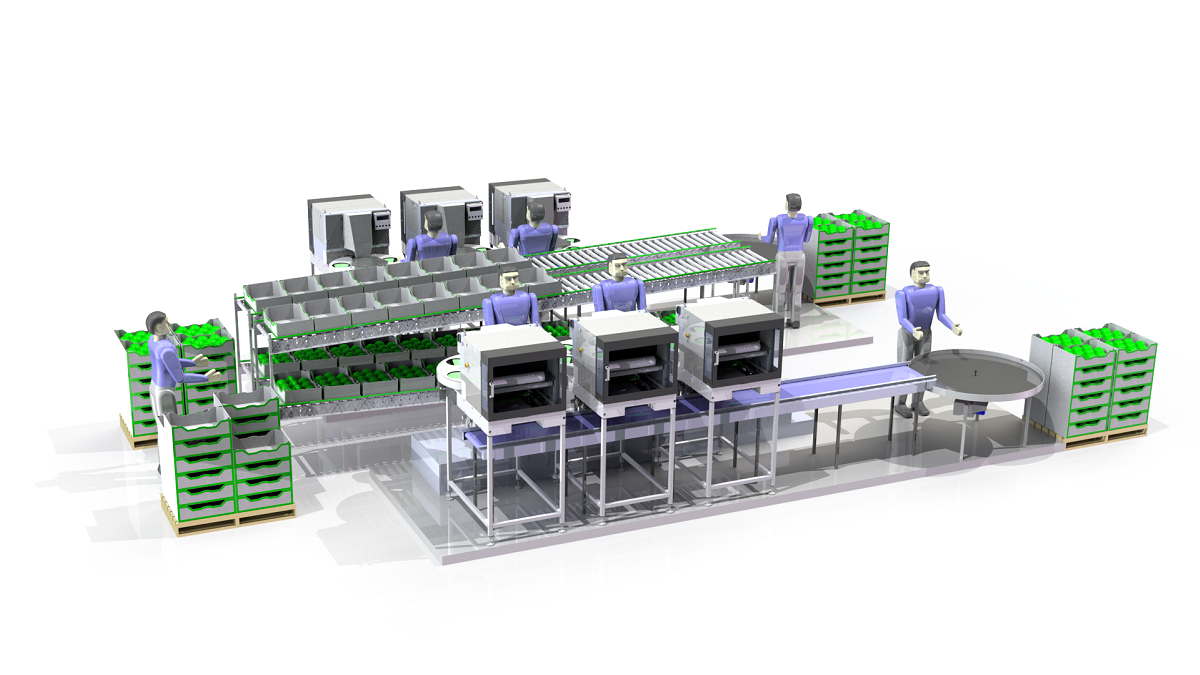

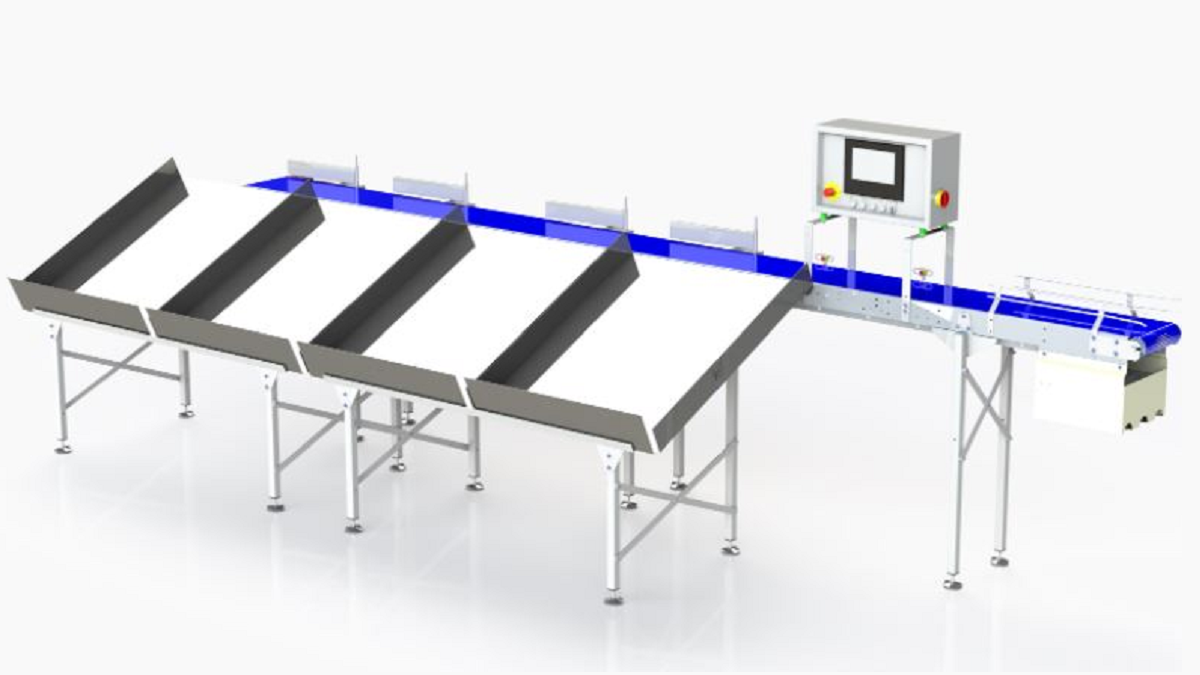

The Columbia 12/7 harvesting rig is equipped with the VeTrac e-Drive unit and seven VePack 200 Iceberg Lettuce Packaging machines. The harvesting is done at 12 meters wide, this allows harvesting up to 30 lines of lettuce.

BrimaPack’s unique e-Drive system is lowering fuel costs and greenhouse gas emissions drastically and is giving you optimal drivability suitable for today’s demands and future expectations. The unit also has a Wireless Remote control.

The VeTrac e-Drive is powered by the on-board generator or directly of the power grid, and has multiple advantages and unique characteristics compared to the conventional harvesters and machine carriers.

Due to the quick connection system of the Header and logistical units, the time between harvesting and getting ready for transit to the next field is approximately 20 minutes with 4 people. The build-up time is similar.

See the Las Primicias Columbia VeTrac e-Drive Harvesting Rig in the following video.

BrimaNaut System

Already on the second day of commissioning the BrimaNaut Data monitoring and acquisition system proved its value. Together with the customers project team we could monitor the performance of the harvester from the comfort of the hotel. Besides the performance it also includes the Remote service and diagnostics for the Header with the packaging machines and drive unit.

It delivers data acquisition for: Production information, GPS coordinates, Error and operator messages, Run hours, Shift information and maintenance check on engine and compressor. By using the WLAN access point, this information is even accessible from your smart phone.

On Picture 3 you can see the live performance monitoring of the system via mobile phone. Giving you the total production of today, the average production over the last hour and the current production of 7332 heads per hour. Which are impressive numbers knowing that during this day Las Primicias was running with 15 people. Numbers which cannot be achieved with any other automated packaging concepts at this moment.

Fruit Logistica 2020

During the Fruit Logistica 2020 in Berlin on 5 – 7 February 2020 we will have exciting news and show our latest innovations.