Brimapack

Conditioning

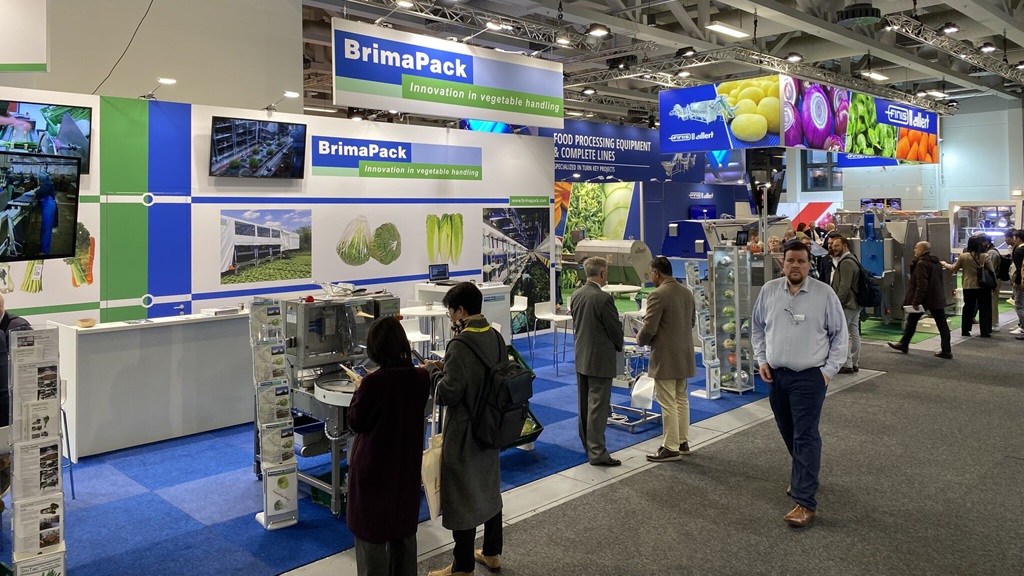

BrimaPack Drives Packaging and Harvesting Innovation at Fruit Logistica 2025

At Fruit Logistica 2025, BrimaPack unveiled its groundbreaking packaging solutions, focusing on automation in vegetable harvesting and packaging to enhance efficiency and reduce costs

With over 60 years of experience in developing customer-oriented solutions for the agri-food industry, BrimaPack has solidified its position as a leader in vegetable packaging. During this year’s Fruit Logistica event, the company introduced its latest innovations in vegetable packaging, bundling, and labeling.

Advanced Vegetable Packaging Solutions

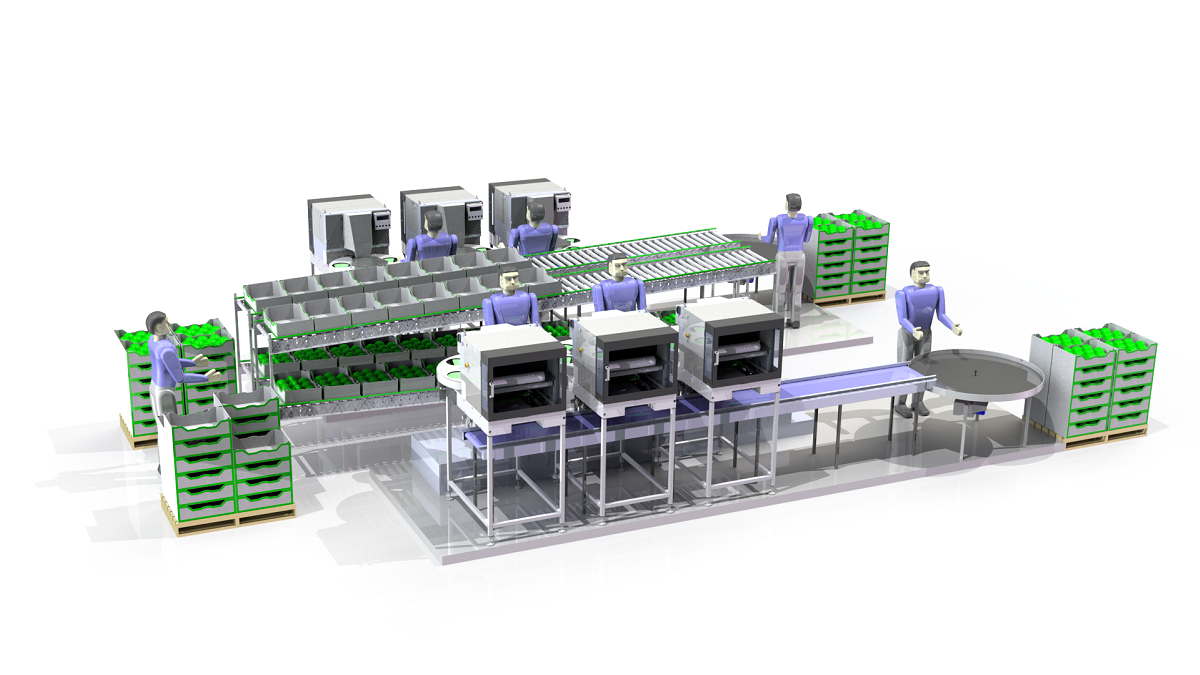

BrimaPack offers a comprehensive range of products designed to optimize vegetable packaging, extend shelf life, and significantly reduce packaging costs. Some of its key solutions include:

- VePack P Series: Featuring NicePack technology and C-PP film packaging machinery, providing efficient, high-quality packaging.

- VeSort: Vegetable sorting systems that streamline the packaging process and improve overall efficiency.

- VeCode: Inline labeling and printing solutions that ensure precise product traceability.

- VeTrans: Tailored logistics systems designed to optimize workflows and complement BrimaPack's solutions.

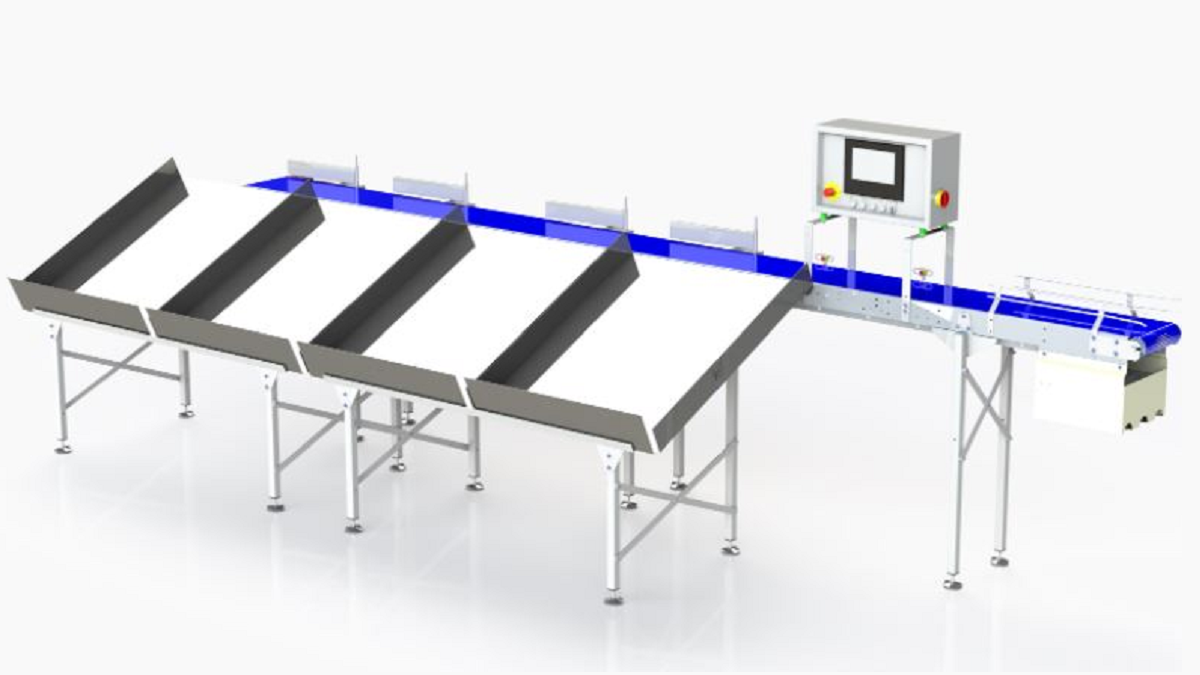

NicePack: Maximizing Freshness and Minimizing Costs

A standout innovation from BrimaPack is the NicePack packaging system, engineered specifically for products such as iceberg lettuce and broccoli. Thanks to its advanced technology, NicePack offers a significantly longer shelf life compared to traditional solutions, while cutting packaging costs by up to 50%.

Additionally, BrimaPack has developed state-of-the-art self-propelled platforms designed for field operations. These machines not only efficiently transport products but also harvest with exceptional precision. The E-Drive system incorporated into these platforms optimizes fuel consumption and reduces emissions, underscoring BrimaPack's commitment to sustainability.

Revolutionizing Automatic Harvesting and Packaging

At Fruit Logistica 2025, BrimaPack introduced its latest game-changer: the Romaine / Gen Triple Bed Lifter, an automatic harvesting machine specifically designed for romaine lettuce. This innovative system automates both the harvesting and packaging processes, eliminating the need for manual labor and marking a major milestone in the automation of vegetable production.

With its continued dedication to innovation and efficiency, BrimaPack is setting new standards in the vegetable packaging industry, offering solutions that improve freshness, reduce costs, and optimize production processes.