Brimapack

Packaging

BrimaPack's innovations 2018

The multi-purpose Harvesting/Planting Rigs and extended shelf life enhancements

BRIMAPACK BV announced some exiting new innovations for 2018: “During the Fruit Logistica 2018 in Berlin on 7 – 9 February 2018 we have shown our latest innovations”, Ron van de Pavert, BrimaPack’s CEO, says. "We are currently assembling our VeTrac 18 rows Transplanter. Also the VeTrac Celery harvester is on its way. In addition, the flat white cabbage (Coolwrap) can now also be packed on our "VePack 200P" packaging machine, delivering a considerable shelf life improvement".

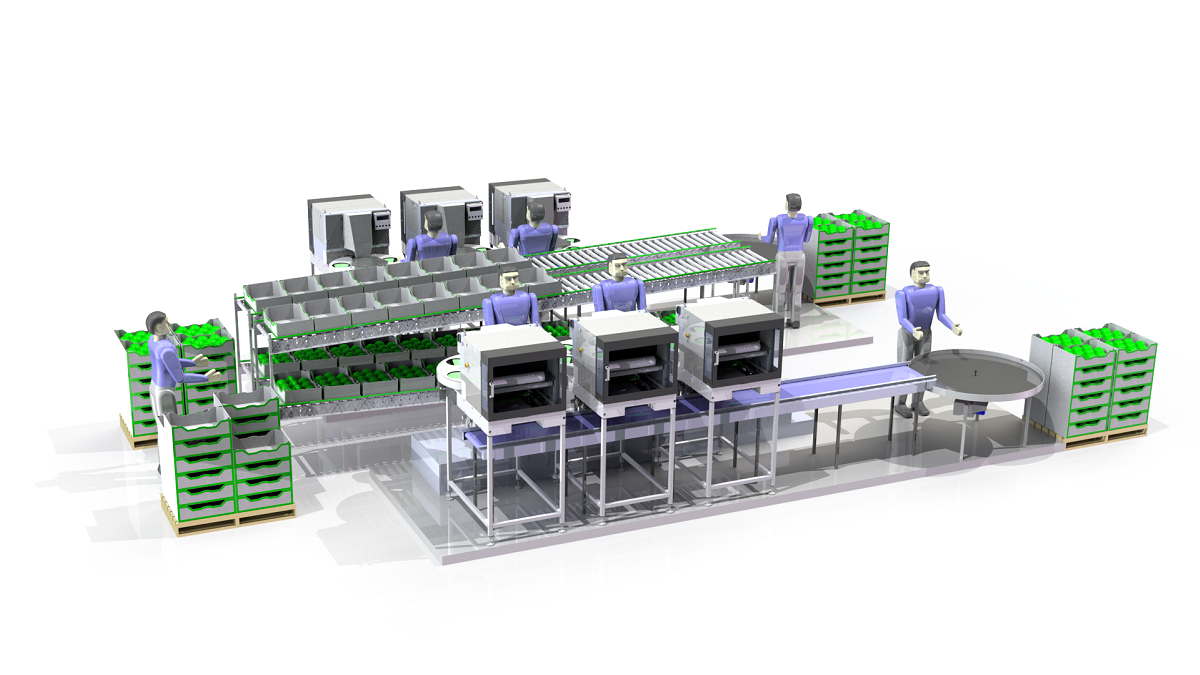

The versatile BrimaPack Harvesting/Planting Rigs

BrimaPack is currently building the 18-row planter. The 18-row planter is attached to the VeTrac e-Drive from BrimaPack. The VeTrac is suitable for harvesting iceberg lettuce, celery and other vegetables. The vegetables are manually cut and placed on special conveyors and packaged on the field with our “VePack 200P” systems or with a flow packer. BrimaPack’s unique e-Drive system is lowering fuel costs and greenhouse gas emissions drastically and is giving you optimal drivability suitable for today’s demands and future expectations.

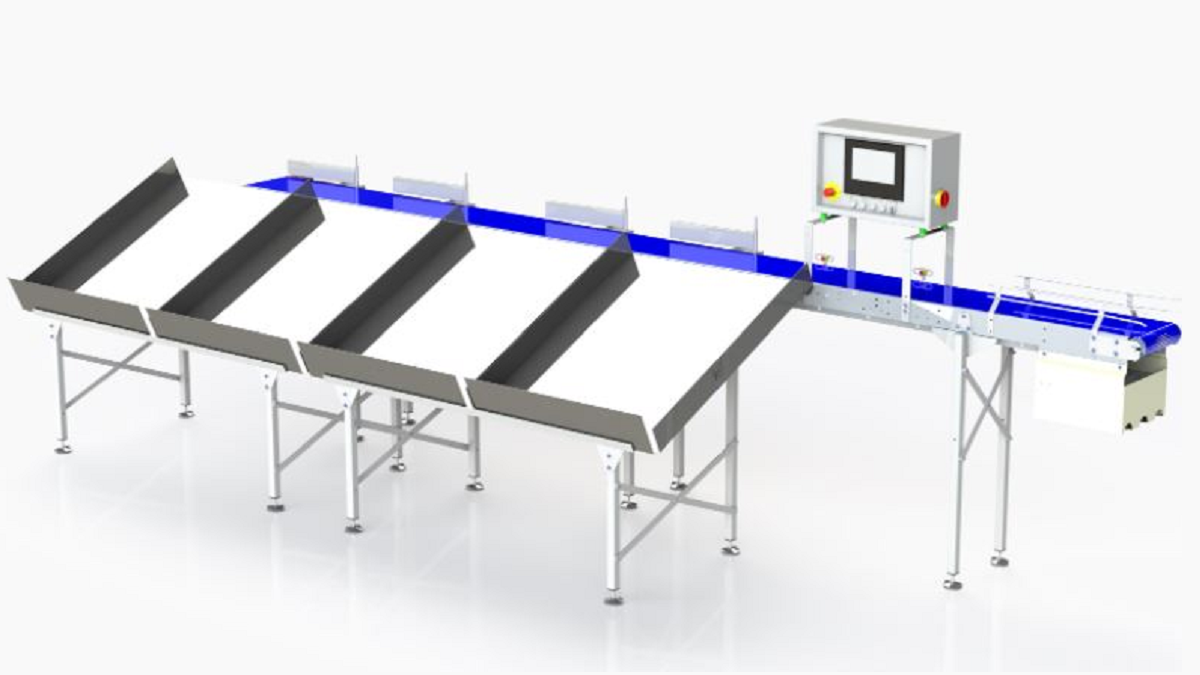

Flat white cabbage on the VePack 200P

With the "BrimaFilm AF" and our packaging machine "VePack 200P", the shelf life of broccoli is extended by 5 to 8 days, compared to conventional types of packaging. This type of packaging is already in use all over Europe. Now the packaging system is also applicable for the flat white cabbage variety. The shelf life of the cabbage is extended with weeks.