Catalytic Generators

Cooling and CA

Tips for Mango Ripening

Catalytic Generators provides a series of recommendations for ripening mangoes to enhance customer satisfaction and sales

Ripening protocols, sometimes referred to as pre-conditioning, have a positive impact on consumer satisfaction and consequently, sales. Consumers have shown a preference for the taste and quality of fruit that has undergone the ripening process. Therefore, it is worthwhile to invest time and effort into offering a range of ready-to-eat mangoes.

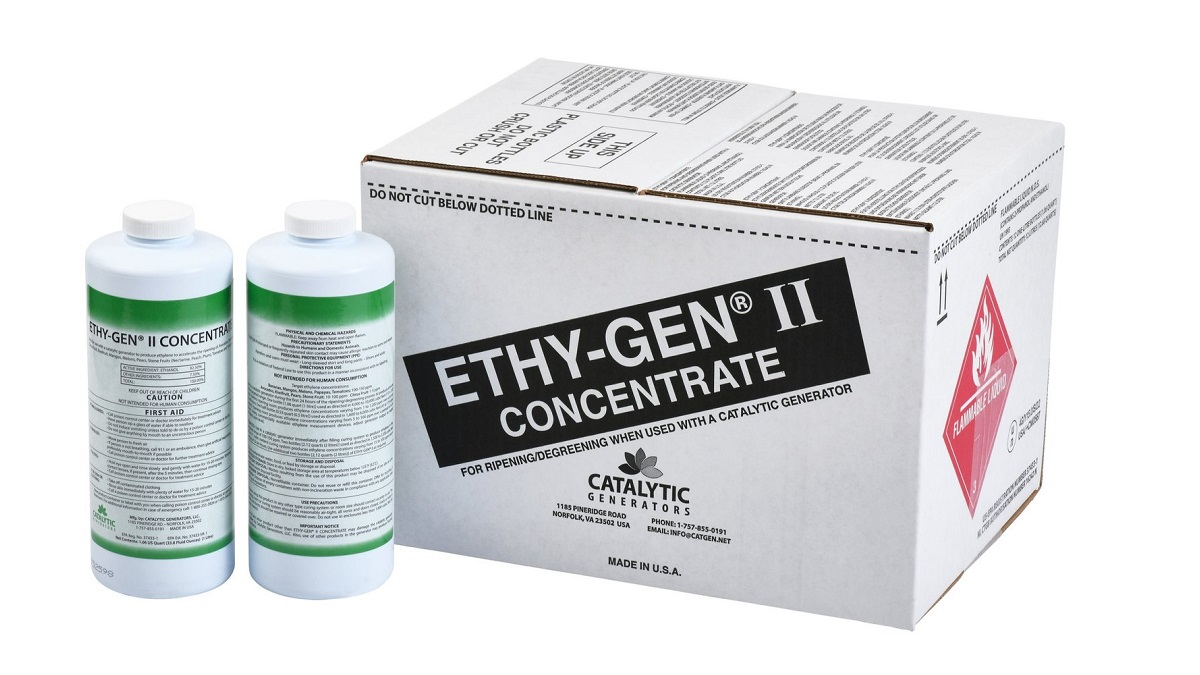

With over 50 years of experience in fruit ripening using ethylene, Catalytic Generators has compiled a set of tips to assist ripeners throughout the process:

Maturity Assessment

During the ripening process, it is crucial to assess the internal ripeness level of mangoes. While external color can provide some indication, determining other maturity indices such as pulp firmness and Total Soluble Solids (TSS - ºBRIX) is key. The US National Mango Board (NMB) provides tables to assist in this regard. Below are links to penetrometers and refractometers to determine the appropriate fruit firmness and TSS content.

Ripening Chambers

Forced air ripening systems yield the best results, providing an extended shelf life after ethylene treatment. Removing heat from the mango is essential for better mangoes when conditioned with ethylene.

Heating Period and Ethylene Application

Before ripening begins, it is vital to raise the fruit pulp temperature to 16.7 to 20°C. After this heating period, during which the fruit pulp temperature stabilizes, apply 100-150 ppm of ethylene for approximately 48 hours. The exact treatment time depends on fruit maturity, time of year, country of origin, and mango variety.

Why do we apply ethylene to mangoes?

Ethylene is a natural plant hormone that converts the starch in climacteric fruits into sugar. In natural conditions, bananas and mangoes emit a low amount of ethylene compared to apples, pears, and avocados. This is why we aid fruit by applying exogenous ethylene for faster and uniform ripening.

Humidity

Maintaining humidity between 90 and 95% is crucial.

Carbon Dioxide

Similar to ripening avocados, bananas, tomatoes, and other fruits, CO2 will accumulate during ripening. If an automatic ventilation system is unavailable, ensure the chamber is ventilated every 12 hours by opening the doors for 20 minutes, even during ethylene application. CO2 levels should be kept below 1% for proper ripening.

Post-ethylene Application / Storage Temperatures

After ethylene application, keep the pulp temperature between 16.7 and 20°C until the desired ripeness level is achieved. Mango pulp ripening and softening will continue at a consistent rate once they have received the ethylene treatment.

To preserve shelf life, for all varieties except Kent and Honey, store ripe fruit at 10°C in a high humidity environment and promptly send it to its final destination. To prevent cold damage in Kent and Honey/Ataulfo, avoid storing below 12.2°C.

For more information on mangoes and other fruits, visit the UC Davis Postharvest Technology Center website. A great resource for any fruit ripener is a UC Davis publication titled "Fruit Ripening & Ethylene Management." Another resource is the maturity tables from the US National Mango Board.