Catalytic Generators

Cooling and CA

Trofi Pack's Experience with Catalytic Generator Installation for Fruit Ripening

Sidney Van der Maal from Trofi Pack shares his experience with the installation of fruit ripening equipment from Catalytic Generators, highlighting how the use of ethylene improves the quality and uniformity of ripening, reduces costs, and simplifies the process, achieving impressive results in his work with avocados

In the world of fruit ripening, efficiency is the key. Sidney Van der Maal, an experienced professional at Trofi Pack, Dutch based service provider specializing in cooling, ripening and packaging of exotic fruits, shares his journey and feedback on the installation of Catalytic Generators, highlighting the transformative impact of ethylene in the ripening process.

Having previously worked with ethylene and gas cylinders at Westfalia Fruit in Poeldijk, Van der Maal was familiar with the benefits of ethylene in ripening. However, upon transitioning to a new company, he faced the challenge of adapting to a different setup. Despite initial concerns, his encounter with Catalytic Generators proved to be a game-changer.

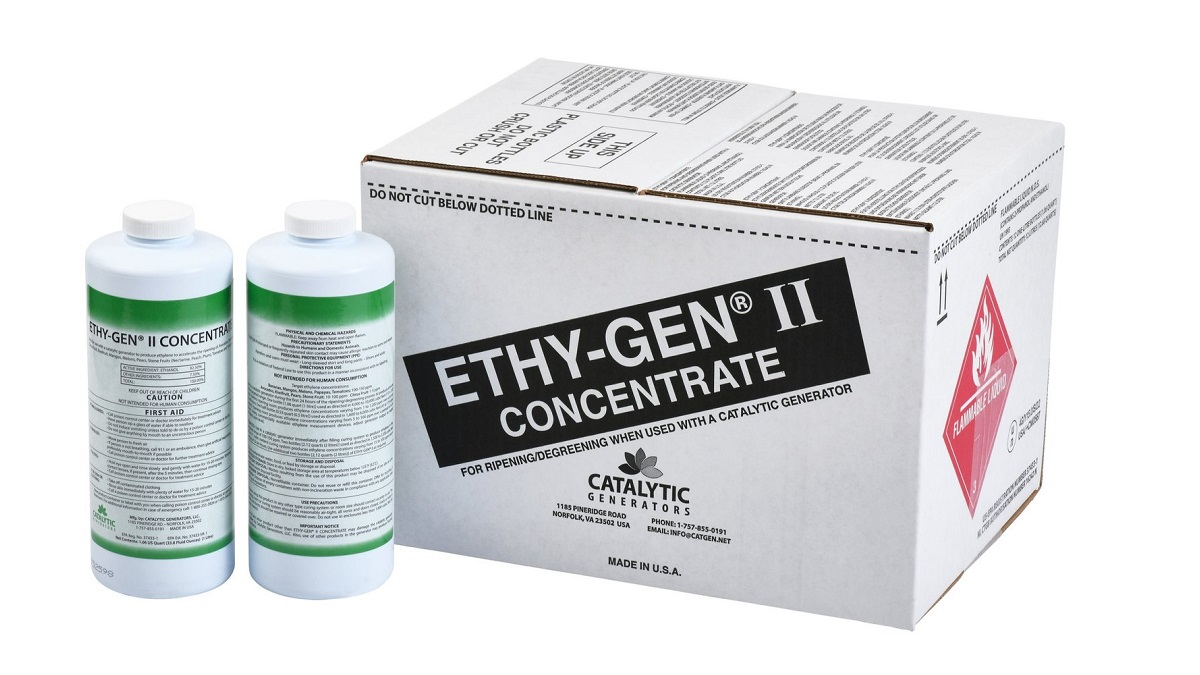

"When I came here, Trofi Pack had not been using ethylene for ripening", Van der Maal recalls. Determined to optimize the ripening process, he engaged in dialogue with management, which eventually led to the adoption of Catalytic Generators and Ethy-gen® II Ripening Concentrate. The results were remarkable.

Van der Maal emphasizes that integrating Catalytic Generators into his workflow was very easy. The advantages of ethylene in ripening are undeniable, as Van der Maal highlights its role in ensuring uniform ripening, minimizing fruit stress, and enhancing overall quality.

Van der Maal explains:

"When I look at the quality of the fruit, with and without ripening with ethylene, without ethylene, it's more difficult, and you have to use higher temperatures. This increases stress on the fruits, significantly reduces shelf life, and increases defects. With ethylene, the fruits ripen more evenly, with uniform pressure and ripeness, resulting in less sorting on the packing line and happier customers because they receive uniformly ripened fruits,"

Primarily working with avocados, Van der Maal attests to the efficacy of Catalytic Generators in delivering optimal ripening results. Despite initial skepticism regarding the generator's size and capacity, he was pleasantly surprised by its performance, achieving consistent results across different ripening rooms.

"It is really easy to use. I was surprised by the product because I was initially skeptical about this small generator. I was used to working with gas installations and cylinders. Then I got a small box and some bottles of liquid Ethy-gen® II Ripening Concentrate. After the first results, I was surprised. I came back Monday morning, checked the ripening room, and saw that I had the same results as I used to have with the entire cylinder installation. So I am really happy with it."

Later, Van der Maal's team experimented with adjusting the generator's settings to match the needs of the ripening process. The generator's versatility and ability to seamlessly transition from one ripening room to another, consistently delivering excellent results, was highly appreciated by Van der Maal. Of course, generators can also be integrated into ripening room software, allowing them to be controlled from a control panel.

Van der Maal concludes:

"I could make a long story about it and how complicated it is, but it's not complicated after all. The fruits need good ripening results, and ethylene helps a lot. Quality is the most important. If you use ethylene with good quality fruits, you will have better-ripened fruits than without ethylene"

Moreover, Ethy-gen® II Ripening Concentrate and generators are about three times less costly than cylinders in terms of expenses. Some customers report saving up to €2000 per ripening room per year, though final savings depend on the cost of cylinders and the amount of ethylene used. An additional advantage is that there is no need to invest in large infrastructure projects like cylinder installations; instead, Ethy-gen® II can be purchased in place of your next order for cylinders as a trial. This allows for a practically "free" comparison, making it easy to understand the benefits.

Fresh Produce Instruments is an official distributor of Catalytic Generators’ products (USA). The Easy-Ripe® Generators provide consistent, non-pressurized ethylene on a continual basis to achieve uniform ripening and degreening. Simply place the generator in the ripening room in a convenient location, adjust the settings, and prepare to be amazed by the effortless and consistently high-quality fruit ripening process.

If you're interested in trying Ethy-gen® II or calculating your potential annual savings on ethylene, please send us your inquiry to info@freshproduceinstruments.com or schedule an appointment at Fruit Attraction, Madrid, Hall 6 Stand E16A.