Citrosol

Phytosanitaries

Challenges and Guidelines to Reduce Postharvest Losses in Tomatoes

The Citrocide® PLUS T System by CITROSOL effectively controls postharvest rot in tomatoes. By Dr. Martín Mottura, Technical Department of CITROSOL

Despite the use of increasingly advanced postharvest techniques, significant losses continue to occur in fresh fruits and vegetables between harvest and consumption. A considerable portion of these losses is attributed to postharvest rot.

Postharvest Rot in Tomatoes

Tomatoes (Lycopersicon esculentum Mill.) are considered one of the world's most important vegetables in terms of the quantity of vitamins and minerals they contribute to the human diet. However, various diseases significantly increase postharvest deterioration and decrease the shelf life of this horticultural product. The main postharvest pathogens affecting tomatoes include Rhizopus spp., Botrytis spp., and Alternaria spp., among others.

Tomato Cracking

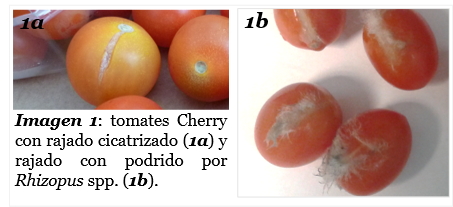

Another cause of losses and complaints in tomatoes is cracking, a physiological disorder caused by a complex interaction of genetic, environmental, and management factors. It is characterized by generally longitudinal cracks that affect the fruit's cuticle, ranging from micro-wounds to wide cracks extending from the calyx to the apex. Beyond the loss of commercial value due to cracking, the main issue is that these wounds become entry points for pathogenic fungi, leading to rot (Figure 1).

Figure 1. Cherry Tomatoes with Healed Cracks (1a) and Cracks with Rot Caused by Rhizopus spp. (1b)

The Multiplicative Effect

In the case of tomatoes, postharvest problems are exacerbated because a significant portion of the market involves various pre-packs (mesh bags, trays, containers, etc.). This is particularly critical for cherry tomatoes due to the large number of fruits per package. In such packaging, just one rotten tomato within a container leads to the rejection of the entire unit for sale, thus multiplying the impact of a single rotten fruit by the weight of the entire pre-pack.

Figure 2. Tray of Cherry Tomatoes with a Rotten Fruit

Guidelines and Solutions to Reduce Postharvest Losses

Similar to all fruits and vegetables, there are general guidelines that must always be followed to minimize postharvest losses. Some of the most relevant include good harvesting practices, proper temperature and humidity control throughout the postharvest process, and maintaining proper hygiene in the horticultural center. Regarding tomato cracking, despite being a complex physiopathy, there are management guidelines that can help reduce its incidence. Some of these include proper irrigation and nutrition management in the field, controlling humidity and greenhouse ventilation, and avoiding abrupt thermal shocks to harvested fruit.

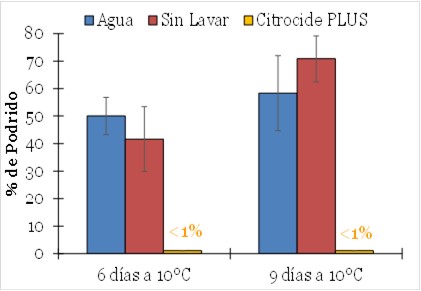

In postharvest processing, the Citrocide® PLUS T System developed by CITROSOL effectively controls postharvest rot in tomatoes (Figure 3).

Figure 3. Rot percentage in Daniela tomatoes with wounds washed with Water, Unwashed, or washed with the Citrocide® PLUS T System, after 6 and 9 days of storage at 10ºC.

Moreover, this comprehensive tomato washing system enhances the food safety of the final product by inactivating all types of microorganisms, both those causing rot and those potentially harmful to humans. It leaves no residues on the fruit and is suitable for use in organic farming since Citrocide® PLUS is certified by CAAE for this purpose, in addition to being certified as a vegan input.