Citrosol

Phytosanitaries

Recommendations for the Treatment and Packaging of Citrus Fruits

By Dr. Rafael Torregrosa, Technical Department of Citrosol, for CITROPOST

Once the fruit has been conditioned and treated upon arrival at the fruit and vegetable packinghouse, it proceeds to the packaging process in the selected formats. This process takes place in a continuous production line consisting of several key stages: washing, pre-drying, waxing, drying, sorting, and final packaging (in boxes, nets, etc.).

Washing

The fruit must be thoroughly washed to remove dust, fungal spores, bacteria, and soluble residues from pre-harvest treatments. The washing process should be performed using a neutral or alkaline soap, along with a disinfectant, preferably Citrocide®, ensuring that the fruit is completely rinsed to eliminate any residue from the products used.

Pre-Drying Tunnel

It is essential that the fruit enters the pre-drying tunnel free of soap residues, and that accumulation of fruit at the entrance is avoided. The tunnel temperature should be adjusted to dry the fruit uniformly before it enters the wax applicator, ensuring that hot air does not directly impact the fruit. The relative humidity within the tunnel must be kept to a minimum, and the equipment should remain clean, disinfected, and in optimal operational conditions to ensure process effectiveness.

Coating (Wax)

During washing and disinfection, the fruit’s natural wax is removed, so it is crucial to apply an appropriate coating. This coating must:

- Restore the protective function of the fruit's natural wax, safeguarding the fruit from external agents.

- Prevent dehydration and allow gas exchange (O₂ and CO₂).

Additionally, coatings usually include a dose of fungicide (typically imazalil) as a reinforcement. To ensure greater stability and reliability, it is recommended to incorporate the fungicide directly during the coating formulation, rather than adding it in storage. This approach ensures that the formulations undergo strict quality control, such as that provided by CITROSOL, guaranteeing a more consistent and efficient final product.

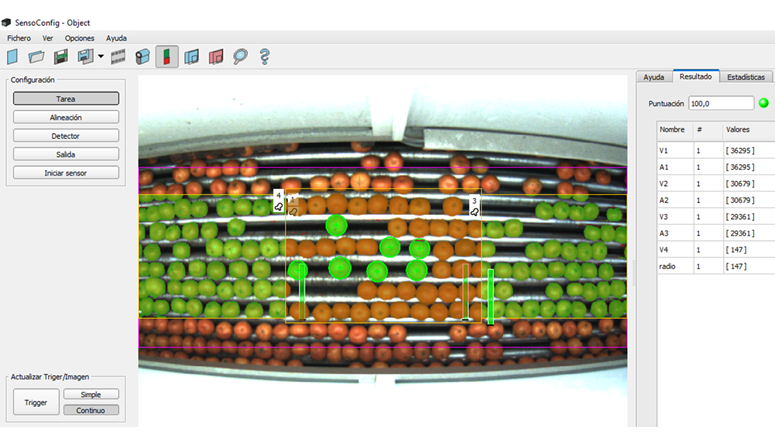

CitroVision System

The CitroVision system optimizes wax consumption by establishing a precise relationship between the amount of fruit passing through the line and the amount of wax applied, using Artificial Vision technology. The new version of the system significantly improves fruit volume detection and calculation thanks to cameras connected to the cloud. This allows the system to process and efficiently utilize all the generated data, adapting to different production lines, as well as any morphology and color of citrus fruit. Its robust design ensures reliable performance in diverse operational conditions.

Wax Applicator

Proper functioning of the wax applicator is essential to achieving a uniform and effective coating. Key considerations include:

- Cleaning and maintenance: The brushes must be clean and dry before starting operations. They should be replaced if they show signs of wear.

- Rotation speed: The speed of the brushes should be adjusted according to the fruit variety to ensure optimal wax distribution.

- Dose control: The wax application should be consistently maintained at 1.0 liter per ton of fruit.

- Insufficient dose: May result in defective coatings, reduced shine, uncontrolled weight loss, and insufficient fungicide levels, when included in the formulation.

- Excessive dose: Can lead to issues such as foam formation, stickiness, dirt accumulation on the line, and excessive fungicide residues beyond acceptable levels.

Precise control of these parameters ensures effective coating, maximizing fruit quality and shelf life.

Drying Tunnel

The drying tunnel plays a crucial role in properly forming the wax film on the fruit. It is vital that the temperature is appropriate to ensure uniform and effective drying. The recommended temperature ranges are:

- 30-38 °C for low-temperature drying waxes.

- 38-45 °C for standard waxes.

Operational guidelines should follow the same procedures as those in the pre-drying tunnel: regular cleaning, disinfection, and maintenance in optimal conditions. This ensures efficient operation and a high-quality finish.

Conclusions

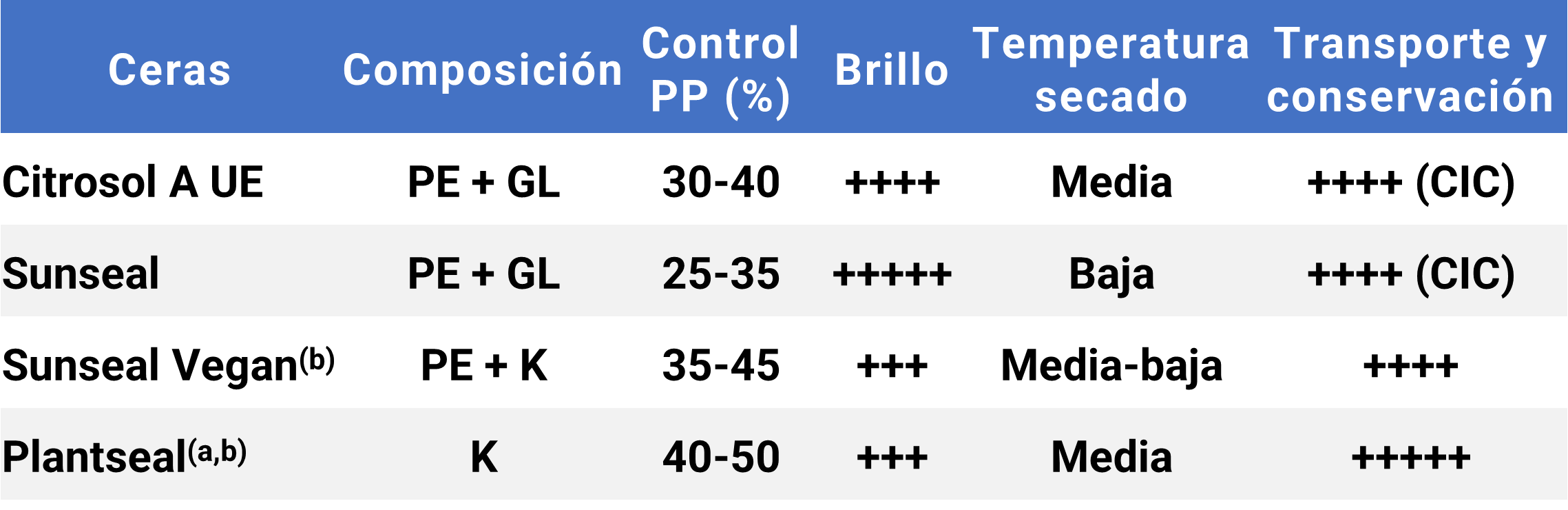

The application of the coating is a critical point to ensure optimal storage and conservation conditions for the fruit. Choosing the right formulation is essential for achieving the best results. CITROSOL offers a wide range of coatings designed to meet the specific technical and commercial needs of each customer.

PE – Oxidized Polyethylene Wax

K – Carnauba Wax

GL – Shellac Gum

Organic Certification (a) and Vegan Certification (b)