FAM STUMABO

Processing

Cutting solutions for plant-based meat and cheese alternatives

Empowering processors of alternative proteins & new food

With people more than ever being aware of a healthy lifestyle, climate change and animal welfare, it’s no surprise that the market for alternative proteins and new foods, in a short period of time, has grown from a booming trend to a full-fletched food segment.

Besides the more traditional vegetarian and vegan products such as seitan, tempeh and tofu, alternative proteins are now also widely available in the form of analog cheeses and a variety of meat replacers.

Among the alternative sources of proteins are plant-based, fungi-based, lab-grown, algae-based and insect-based proteins. Each of these sources come with specific processes and challenges when turning them into attractive, ready-to-eat consumer products.

Our experience - Your benefit

At FAM Stumabo, we have nearly half a century experience in cutting a wide variety of ‘traditional’ food products such as vegetables, fruit, potatoes, cheese, meat, poultry, fish, etc.

This has offered us a wealth of experience in cutting products with different textures, hardness, moisture levels, temperatures and elasticity into the most diverse shapes and sizes. This strong background has put us in the pole position to assist processors of alternative proteins with their production of new and innovative cut shapes and sizes of their latest food ideas.

A multitude of processors of alternative proteins around the world already rely on FAM Stumabo’s solutions for cutting products like meat replacers and analog cheese.

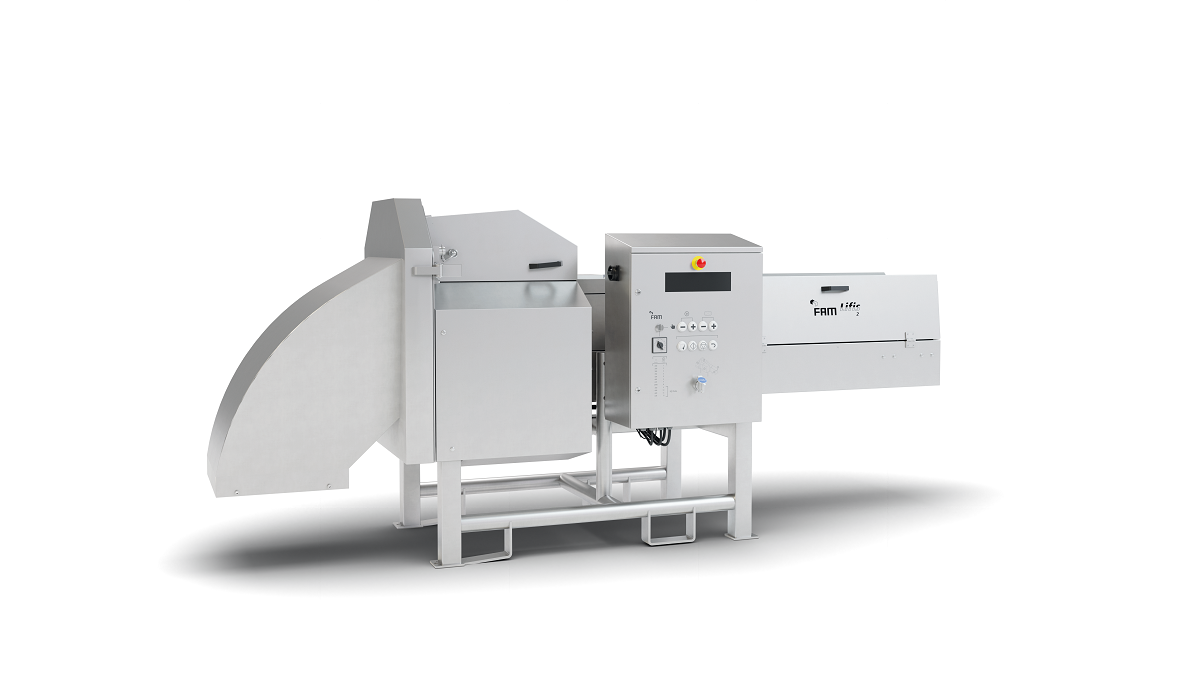

Our range of solutions include belt dicers, drum dicers and centrifugal cutting machines. Our in-house blades division designs and manufactures dedicated knives and cutting tools, perfectly aligned with our cutting equipment.

The market for alternative proteins is still in full development, with new food products becoming available on supermarket shelves as we speak.

At FAM Stumabo, we approach this market with an open mind and our typical together-approach, always reaching for the perfect solution to cut your specific product in the desired shape and size.

Cutting solutions for meat replacers

Choosing the right cutting equipment is a critical, often underestimated step in the production process of alternative proteins. No matter how good the recipe and taste, it’s the right cut shape and quality that can ‘make or break’ your product in the supermarkets.

Most of today’s alternative meat products are produced by an extrusion process. Therefore, their consistency, viscosity, moisture content and temperature differ significantly from that of traditional meat products, having an important impact on the cutting process. Alternative meat products often need to resemble the look, texture, mouthfeel, taste and cut sizes of traditional meat products.

For alternative meat products, cut quality is not necessarily related to precise cutting. It’s about creating exactly the desired natural-looking strip, dice, chunk, or hand pulled look shape and size with respect to texture, moisture and viscosity.

Whether you are a ‘traditional’ meat processor or a start-up company entering the alternative meat segment, don’t let your cutting challenges set back your new product development. Come talk to FAM Stumabo to discuss your specific needs.

The FAM Yuran™ Hytec belt dicer can be equipped with dedicated cutting tools and claws for cutting and pulling plant-based, alternative meat and poultry-like products into chunks, strips and hand-pulled look shapes.

Cutting solutions for analog cheeses

Plant-based cheese alternatives can be challenging to shred, grate, or dice. As a leading manufacturer of cheese cutting technology, we have dedicated a lot of research and development on quality cutting of analog cheese variants. Machineability and in particular shreddability and diceability of a cheese analogues play a key role for specific applications such as pizza and toppings by facilitating its utilization and accelerating melting behaviours. The shreddability and diceability of cheese are influenced by a set of material characteristics and is mainly controlled by a fine balance of its viscoelastic behaviour.

Soft cheeses, which have relatively high moisture contents, low storage moduli, and high surface energies, exhibit strong blade adhesion during cutting, which decreases their shreddability and diceability. At FAM Stumabo, we are closely working with research institutes as well as manufacturers to better understand the textural behaviour of plant-based cheeses and translate that knowledge into high performant dicing, shredding and grating equipment.

Our cutting solutions take into account a combination of parameters like temperature, speed, special cutting tools, different knife materials, etc.

Come talk to FAM Stumabo to discuss your specific needs for cutting analog cheeses.

Cutting solutions for other new food products

Not only alternative and new food ingredients and products are booming. Also, more traditional food products are constantly evolving, with new products entering supermarkets almost daily. And so is the need for specialized and dedicated cutting solutions that must anticipate the next evolutions in food processing.

Whether you are looking to cut new ingredients and products, or you look to innovate or diversify your existing product offer by adding new cut shapes or sizes, our dynamic team of application engineers, cutting experts and food scientists is looking forward to helping you with any specific request.

Contact us for expert advice and a free cutting trial at one of our food cutting labs around the world.