FAM STUMABO

Processing

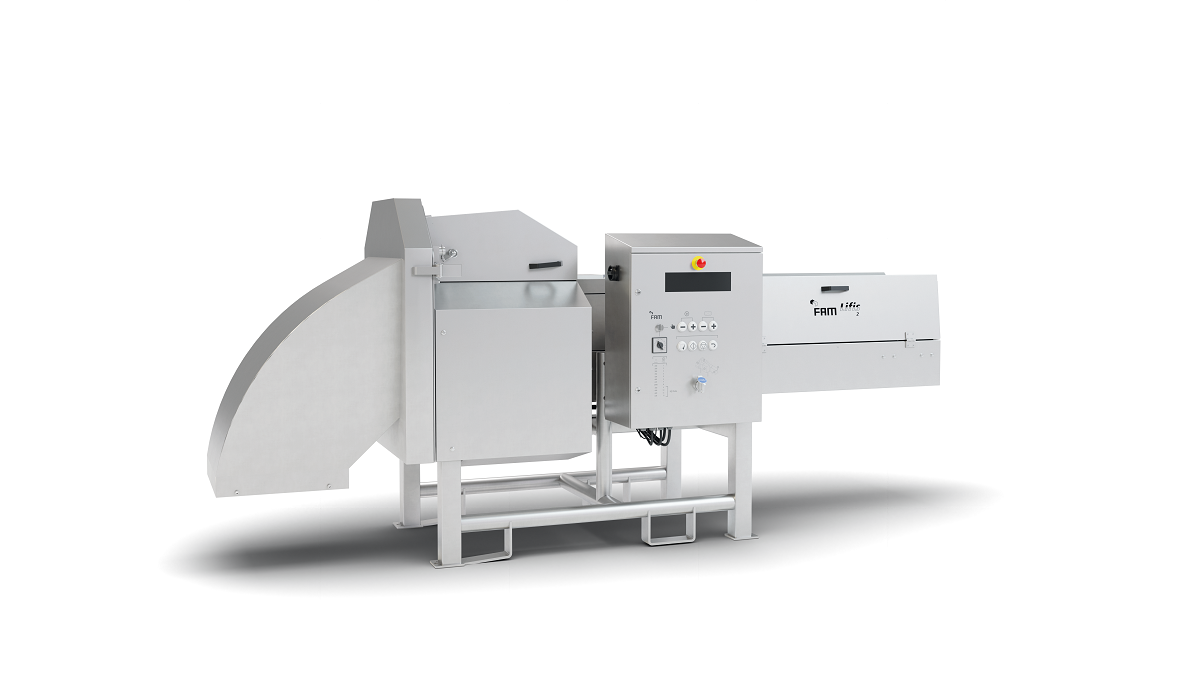

FAM STUMABO unveils the Yuran™ Hytec 300 EC – now featuring an Exit Conveyor for enhanced efficiency

After the successful launch of the Yuran Hytec 300 in 2024, FAM STUMABO will release an additional version of this model at the IFFA 2025 exhibition in Frankfurt, Germany (May 3-8, 2025).

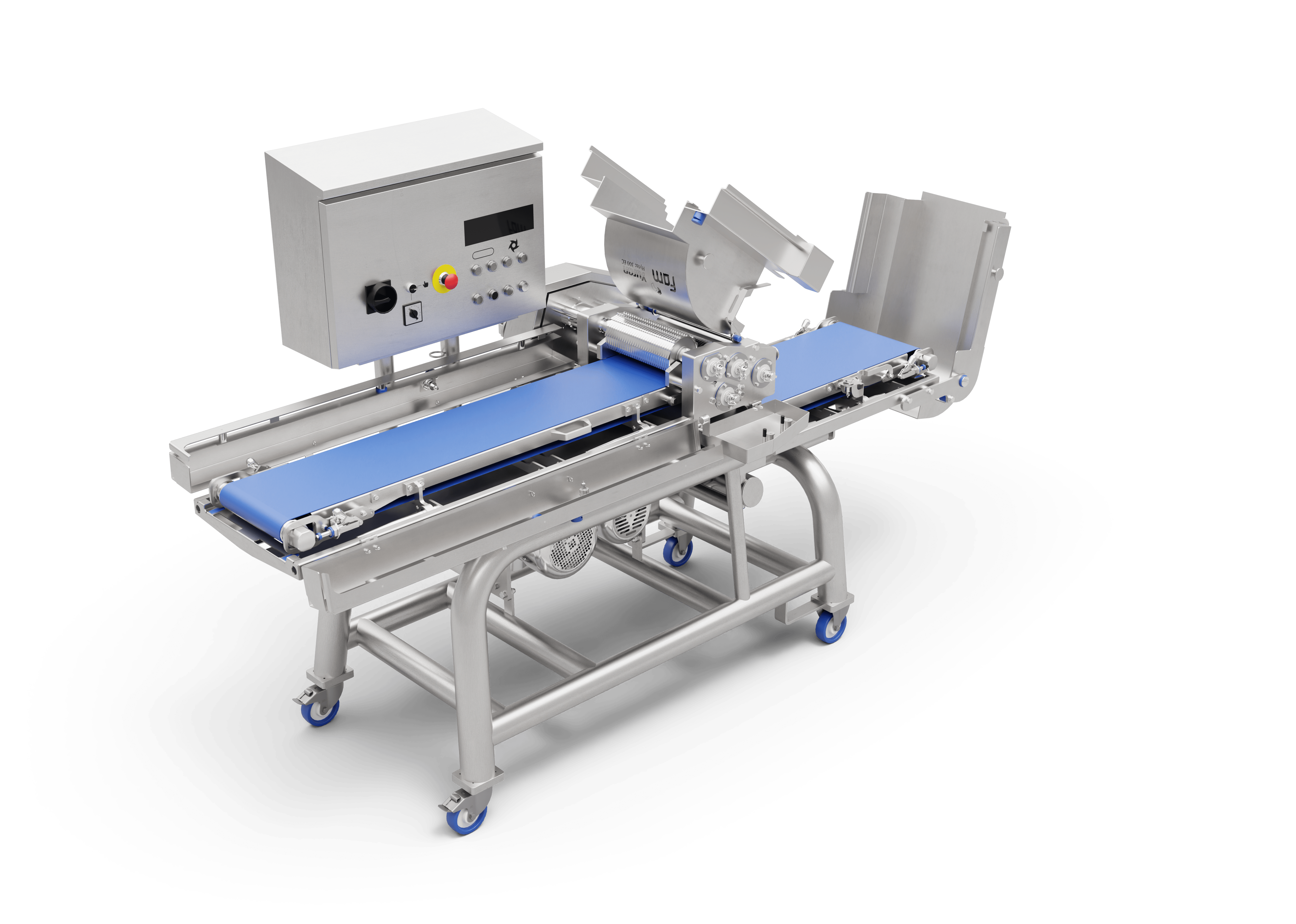

The new version builds on the success of the Yuran Hytec 300, a versatile machine designed to dice, strip-cut, and shred a wide variety of meat, poultry, alternative protein and petfood products. The Yuran Hytec 300 EC integrates an Exit Conveyor that brings several advantages specifically for batch processing.

Thomas Bogaerts, Project Engineer at FAM STUMABO, explains:

“The innovative exit conveyor will help capture the cut pieces effectively and eliminate product loss or spillage. The clearance between the discharged cut product and the integrated conveyor maintains the quality required for even the most sensitive applications. It will further provide a more controlled discharge due to a seamless transition and even distribution of the cut product.”

Efficiency and versatility in batch processing

The new Exit Conveyor system facilitates discharging the cut product into totes, a Eurobin trolley, or additional conveying systems so that there is no need to stop the machine when replacing totes during batch feeding. With its simple operating principle, the Yuran Hytec 300 EC also offers the benefit of ease of use in a variety of applications.

The product is fed via the belt and guided towards the feed roll, ensuring a positive transfer into the circular knives. The circular knives cut the product into strips, which are then diced by the crosscut knife spindle at the desired height or length. For shredding and pulled look applications, the machine also offers the option of a pre-break system for initial reduction in combination with subsequent cutting and shredding spindles.

The Yuran Hytec 300 EC also offers the advantages of:

- Increased capacity with the 300 mm wide conveyor belt that allows an increased feeding capacity, accommodating products with larger dimensions.

- Versatile cutting options with dual independent variable-speed motors that enable precise adjustments to cut size and shape without the need for additional cutting tools.

- Efficient changeovers with the quick-removable splined shafts of the cutting spindles that facilitate fast changeovers from one cut size to another, reducing downtime in the

production process. - Smart hygienic design that ensures easy, thorough, and safe cleaning of the machine.

Versatile cutting solutions for meat, alternative meat products and petfood industry applications

Thomas Bogaerts explains:

“The Yuran Hytec 300 EC is used in cutting fresh, crust-frozen, tempered frozen, and (hot) cooked meat and poultry products. It excels in providing efficient and consistent ‘pulled look’ shredding of cooked beef, poultry, and pork meats, making it ideal for BBQ meats, salad and pizza toppings, sandwiches, and handheld snacks.”

The specialized cutting tools are designed to handle the unique characteristics of extruded products, creating alternative meat products in familiar cuts and shapes.

Bogaerts concludes:

“The Yuran Hytec 300 EC also specifically provides a unique solution to shred, dice, strip-cut a variety of petfood industry applications."

Discover the Yuran Hytec 300 EC at IFFA 2025

Visit the FAM STUMABO booth at IFFA (Frankfurt) in Hall 8, Booth D30, to discover the new dicer and speak with our experts to learn how this solution can enhance your processing line.

Join Thomas Bogaerts (Project Engineer, FAM STUMABO), who will make a presentation on the Yuran Hytec 300 EC at the “IFFA Factory & Stage” (Hall 9.1 – Stand H21) on Wednesday, May 7 th from 11:35 am - 11:55 am, to find out more about this new solution.

About FAM STUMABO

FAM STUMABO engineers and develops industrial cutting machines as well as the manufacturing of precision knives for the food industry. We provide customers with the solutions they need for the cutting, slicing, and dicing of fruit, vegetables & nuts, cheese, meat & poultry, fish, petfood, potato chips and French fries. Over the past 60 years, we have established long-lasting partnerships in cooperation with highly reliable influential companies, customers, and leaders in the industrial food processing market. We are present on all continents, with customer experience centers, spare parts and services.