Grup Giró

Processing

The integration of Serfruit is already giving results: End-to-end machinery solutions and a new case packer BOX-IT

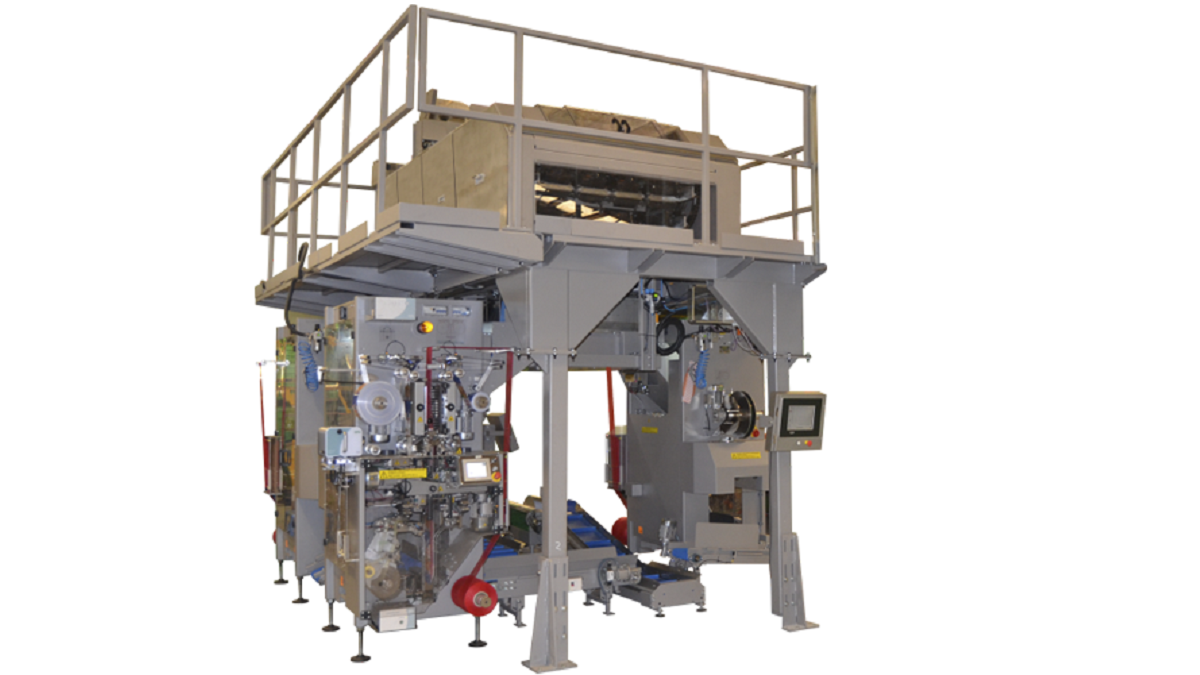

The combined efforts of Giró and Serfruit are already starting to give results. In addition to the possibility of jointly offering personalized automation solutions from beginning to end (turnkey projects), the new BOX-IT automatic case packer was born as a result of the collaboration between the two

A cost-effective, end-to-end, and turnkey solution

Throughout the last decades, Giró has reaffirmed itself as a solid supplier of machinery for the area of weighing, packing, check-weighing, and automatic boxing in fruit and vegetable processing warehouses.

With the firm intention of being able to offer our customers an even larger product portfolio, in 2022 Giró acquired Serfruit, a company known for its customized industrial automation solutions offered for more than 30 years.

Thanks to this acquisition, Giró can now offer end-to-end solutions to automate fruit and vegetable from beginning to end, ranging from the initial dumping of bins, product treatment (washing, drying, and waxing), and grading upstream of the area of packaging that Giró covered before; or the palletizing and strapping systems for pallets after automatic boxing.

Thus, we can design, develop, manufacture, commission, and maintain all types of complex facilities, providing the best-customized automation solution for any type of agricultural or industrial production process, according to the requirements of our clients.

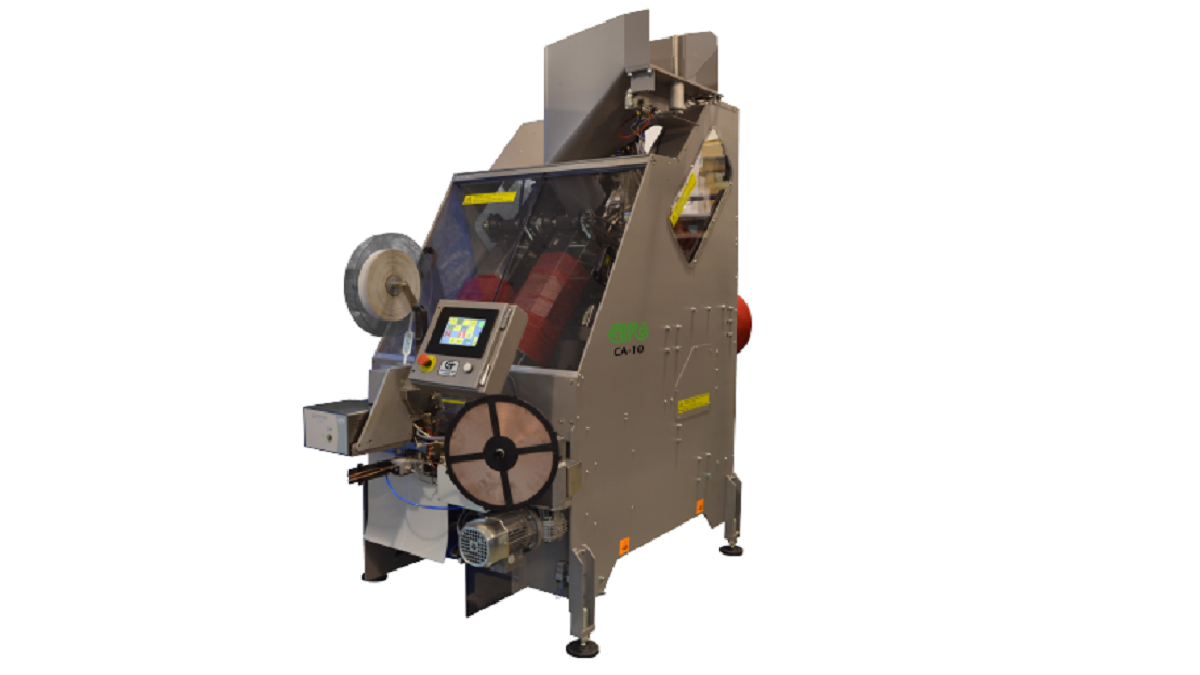

BOX-IT: the new case packer as a launching point

In recent years, Giró has opened the door to a high-speed product range: Speed Line. This product line consists of packing lines with a capacity that can reach up to 80-100 bpm, depending on the options chosen, the format, and the weight of the bag. After renewing the entire line-up of machines, the only machine that remained to be updated was the GBF-100 automatic case packer. For this reason, during 2022 and with the collaboration and expertise of Serfruit, a new case packer has been developed that definitively completes the Speed Line range: the new case packer BOX-IT.

With a capacity to fill boxes at a range of 80 to 100 bags per minute, this case packer combines all the advantages of the GBF-100 case packer and also adds highly requested features that make it an excellent alternative for those processing lines from beginning to end, ranging from the initial dumping of bins, product treatment (washing, drying, and waxing) and grading upstream of the area of packaging that Giró covered before; or the palletizing and strapping systems for pallets after automatic boxing. Thus, we can design, develop, manufacture, commission, and maintain all types of complex facilities, providing the best customized automation solution for any type of agricultural or industrial production process, according to the requirements of our clients. Customers who want to optimize productivity by automating the end of the line.

Among others, the main features of the BOX-IT case packer are:

- Protections and alarms for maximum safety

- Two options for the exit of boxes: with a direct exit conveyor belt or passing through a box checkweigher

- Checkweigher with buffer for two boxes to verify and correct the consecutive boxes with weights outside the target

- Option to use standard boxes of 600x400mm and small size boxes of 400x300mm

Regarding availability, at the end of 2022, we began the market test of the newly developed prototype, and the BOX-IT case packer has been commercially available since mid-2023.

.jpg)