Actualidad

Hot water treatments to improve postharvest behaviour of fruits and vegetables

A review by J.M.D.N Jayasundara et al. that emphasize the importance of HWT in modern postharvest management of produce and minimally processed fruits and vegetables

Fruits and vegetables play an essential role in healthy human diets in day-to-day life. However, they are much more prone to postharvest damage due to their perishable fresh nature. Consequently, these postharvest damages can lead to quality degradation with a lack of consumer acceptance.

Ultimately this can result in a significant wastage of fruits and vegetables, posing economic and environmental challenges. Ensuring the safety and quality of fresh produce is important for consumer’s health benefits, and postharvest techniques, including physical, chemical, and gaseous methods, are employed.

This review focuses on hot water treatments (HWT) as an effective strategy to control decay, reduce microbial load, minimize chilling injury, and preserve the overall quality of fruits and vegetables.

It delves into different HWT methods such as dipping, rinsing, and brushing, examining their impact on extending postharvest life and maintaining postharvest quality attributes.

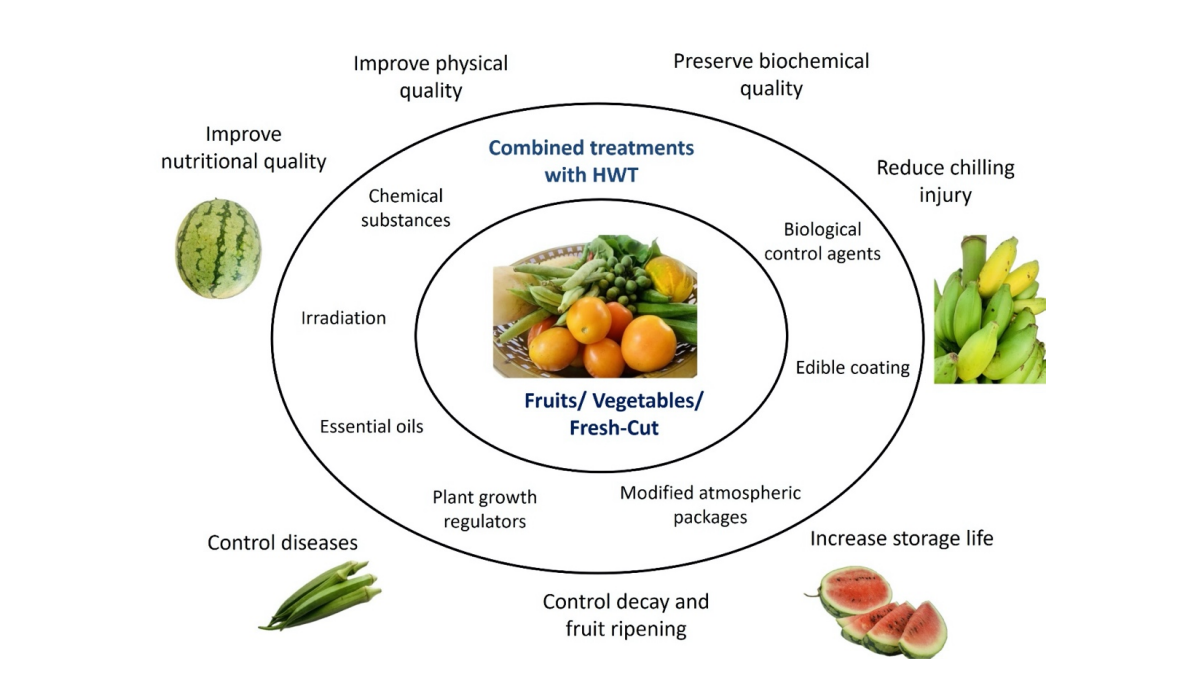

Moreover, the efficiency of controlling postharvest damages of fruits and vegetables using HWT combined with modified atmosphere packaging (MAP), biological control measures, and edible coatings are also explained. Further, this review discusses the broader implications of HWT as an environmentally friendly postharvest treatment solution.

Introduction

Fruits and vegetables are good sources of micronutrients, dietary fibers, and antioxidants that are essential components of a healthy diet (Blasa et al., 2010; Vincente et al., 2014). They provide variety for diets by having different colors, aromas, tastes, and shapes (Fallik, 2011).

Especially they are rich in vitamins C and A. In general, fruits often contain more sugar than vegetables, but vegetables are more likely to include fiber and proteins (Kalmpourtzidou et al., 2020). The consumption of these products may be associated with numerous health benefits such as reducing cancers, heart diseases, stroke, and other chronic disease conditions. Furthermore, they can delay the onset of age-related disorders by promoting good health (Slavin and Lloyd, 2012; Yahia et al., 2019b; Del Rio-Celestino and Font, 2020).

According to Bazzano (2006), the worldwide mortality attributable to inadequate intake of fruits and vegetables is up to 2.635 million deaths per year. Increasing consumption of fruit and vegetables up to 600 g/day could reduce heart disease by 31% and stroke by 19%. World Health Organization and Food and Agriculture Organization currently have given recommendations on the consumption of at least 400 g of fruit and vegetables each day (Kalmpourtzidou et al., 2020).

Fruits and vegetables are perishable agricultural commodities. The process of marketing agricultural commodities is a complex operation due to the services and functions involved in moving the agricultural products from the farm gate to the consumer.

Harvesting of over-matured or premature fruits may result in shorter storage life and low quality (Pokhrel, 2021).

Furthermore, inappropriate and poor postharvest handling processes lead to varying degrees of quantitative and qualitative losses in complex market chains, estimated at 20% to 40% for vegetables and 30% to 40% for fruits (Porat et al., 2018; Rajapaksha et al., 2021).

Harvested fruits and vegetables are metabolically active and they can undergo physical, biochemical, and physiological changes due to ripening and senescence causing modifications of their internal qualities in terms of color, starch content, firmness, organic acid content, and texture, as well as pathological deterioration (Mahajan et al., 2014; Gundewadi et al., 2018). Therefore, these perishable commodities require careful regulation to maintain their quality during postharvest handling. Insufficient management of these processes can lead to substantial reductions in nutritional value and overall quality characteristics (Mahajan et al., 2014).

Currently, quarantine and phytosanitation barriers severely restrict the global trade in fruits and vegetables by limiting the spread of bacterial, fungal, and insect diseases in perishable agricultural produce. These challenges can only be eliminated when fresh vegetables can be treated effectively after harvest (Fallik, 2011). To ensure the quality and safety of fresh produce, a range of postharvest techniques involving physical, chemical, and gaseous treatments have been developed. These treatments are aimed at preserving the nutritional value of the produce while also meeting the required safety standards (Mahajan et al., 2014).

The commercial applications of heat treatments for managing fungal diseases and pest infestations date back to the early 20th century, with the initial discovery of hot water (44 - 48 °C) effectiveness in controlling mold in citrus (Escribano & Mitcham, 2014).

With the development of fungicides and pesticides, the use of heat treatments become economically unprofitable (Geysen et al., 2005). However, the growing interest in the development of ecologically friendly approaches to postharvest management is mainly due to the growing concern about the use of synthetic fungicides, which are considered to be harmful to both human health and the environment (Goncalves et al., 2021).

As a remedy, the use of heat treatments for various purposes such as chilling tolerance, prolonging shelf-life, and preserving fruit quality have been revealed (Lu et al., 2007; Aghdam & Bodbodak, 2014). In addition to lowering the dependence on agrochemicals, heat treatments have the appealing benefit of being relatively simple to apply and they can occasionally be integrated into packinghouse sorting processes.

Fresh fruits and vegetables companies are interested in these techniques together since they are seen as pleasant and safe. Heat treatment is done as a short treatment preceding cold storage and it can be incorporated mainly as forced air, vapor, water baths, water rinsing, and water rinsing with brushing.

Although excessive heat causes adverse effects, the temperature and duration for each type of heat application vary depending on the fruit species, cultivar, size, harvest maturity, and growing conditions (Fallik, 2004; Escribano & Mitcham, 2014). Among these heat treatment methods, hot water treatment is one of the primary techniques employed for fruits and vegetables (Fallik, 2004).

Hot water treatment has been identified as one of the most valuable physical postharvest technologies in the agriculture field (Fallik, 2011). It has numerous advantages over other conventional phytosanitary measures, including comparative ease of use, short treatment time, reliable monitoring of fruits and temperatures in the water, and the killing of skin-borne pathogens that cause decaying (Fallik, 2004).

Furthermore, it has proven to be effective in various applications, including disease control, pest eradication, and enhancing shelf-life (Mahajan et al., 2014). The implementation of hot water treatments can contribute to achieving the nation's sustainable development goals while ensuring safe and high-quality produce for consumers. This ecofriendly goal holds great potential for application in packing houses, primarily due to its cost-effectiveness.

Hence, in this review, mechanisms, and applications of different hot water treatments and their combined effects with other postharvest treatments on fruits, and vegetables for their quality and shelf-life are explored. Furthermore, future prospects and suitability of these aspects with their potential benefits and feasibility are evaluated.

Contents

PRINCIPLES OF HOT WATER TREATMENTS

Types of hot water treatments

Hot water dipping (HWD)

Hot water rinsing and brushing (HWRB)

Factors affecting hot water treatments

The commercial importance of hot water treatments in postharvest handling

Table 1: Applications of hot water treatments for fruits

Table 2: Applications of hot water treatments for vegetables.

Hot water treatments in fresh-cut fruits and vegetables

Table 3: Applications of hot water treatments for fresh-cut fruits and vegetables

MECHANISMS OF HOT WATER TREATMENT

Heat shock proteins (HSPs)

Microbial load reduction

EFFECTS OF HOT WATER TREATMENTS

Effects on defense-related enzymes

Effects on fruit ripening

Effects on chilling injury

Effects on decay control

Effects on physicochemical quality attributes

COMBINATION OF HOT WATER TREATMENT AND OTHER POSTHARVEST TREATMENTS

Table 4: Research findings of the combination of hot water treatment with other postharvest treatments.

Hot water treatment combined with modified atmosphere packaging (MAP)

Hot water treatment combined with biological control methods

Hot water treatment combined with edible coatings

LIMITATIONS AND CHALLENGES IN HOT WATER TREATMENTS

Commodity or substrate damage

External damage

Internal damage

RECOMMENDATIONS AND FUTURE SCOPE

CONCLUSION

Recent studies confirm that hot water treatments offer significant advantages in preserving the quality and extending the shelflife of fruits and vegetables after harvest. This environmentally friendly method effectively controls decay, reduces microbial contamination, mitigates chilling injury, and preserves overall nutritional and functional properties. It stands out as a promising and straightforward technology for enhancing postharvest quality.

Combining hot water treatments with other innovative approaches such as modified atmospheric packaging, biological control agents and edible coatings further improves postharvest quality by preserving the nutritional value of fresh products, thus, prolonging the shelf-life.

Overall, these findings, emphasize the importance of hot water treatments in modern postharvest management for fruits and vegetables.

A Xeda International equipment for hot water treatments

The main figure is Figure 2 of the original paper - The effects of combined treatments with hot water treatments

Source

A comprehensive review of hot wáter treatments of fruits and vegetables for postharvest quality management

J.M.D.N Jayasundara, L.H.N. Sawbhagya, H.M.P.C. Kumarihami, Somsak Kramchote, Elazar Fallik

Journal of Postharvest Technology, 13(1): 1-36

https://doi.org/10.29204/jpht.2025.13.1.1