Actualidad

Fruit Logistica 2024, a winter boost to the horticultural industry

Chronicle of Fruit Logistica 2024

From February 7 to 9 of this year, Messe Berlin, the city's exhibition center, hosted the 2024 edition of Fruit Logistica. The event brought together producers and operators of fresh and processed fruits and vegetables, as well as the suppliers that make this possible, both at the cultivation level and, especially, in post-harvest and processing. It is an event with its energy, complemented by visitors worldwide seeking business opportunities.

According to the organization's figures, this edition had over 66,000 visitors, surpassing the previous edition's figure of 63,470. The exhibitors for this edition, over 2,770 from 94 countries, also exceeded the 2,610 of Fruit Logistica 2023. Within the pavilions, there was a notable rearrangement of some stands, and certain areas were unoccupied this year, such as the City Cube, although others were towards the higher-numbered pavilions. As a visitor, the optimization of space was appreciated, allowing for a slightly shorter walking distance, and there were also convenient rest areas in some pavilions.

The fair continues to be a meeting point full of positive energy, while also being sensitive to the current global and host country's situation, reflected in challenges related to costs for the sector and regions in conflict playing significant roles in the horticultural business.

Drought, the focus of presentations and conferences

Parallel to the fair, company presentations, technical conferences, and roundtable discussions took place in various spaces. GlobalGap organized a panel on addressing responsible water management in regions with high water risk.

Moderated by Chris White, CEO of Fruitnet Media International, a panel of experts or individuals with experience in Southern Europe, including José Luis Molina, CEO of Hispatec Agrointeligencia, discussed immediate measures to alleviate water scarcity. These measures included water reuse, more efficient crop usage, and crop migration. The significance of the topic was evident from the full attendance in the room.

The panel analyzed responsible water management in regions with high water risk

The topics covered included legislation related to water use, governance for the sustainable use of watersheds, water measurement and distribution systems, wastewater management, etc. The role of initiatives for benchmarking and harmonization, certification, and consumer labeling to facilitate, implement, and demonstrate responsible water use at the farm level was considered.

A topic for future forums is the impact of drought in Mediterranean regions on Northern European countries. One reason for reduced rainfall on the coasts of the Iberian Peninsula facing the Mediterranean is the absence of trees on the mountain slopes. The evaporation from these trees contributes the moisture needed for the moist air from the Mediterranean to turn into rain as it ascends the slopes. These moisture-laden breezes, when unable to release their moisture, continue their path towards Northern Europe, causing the floods experienced in Germany, Austria, and other regions.

The University of Wageningen presented its projects in a session that extended throughout the morning of the last day of the fair, aiming to address existing problems and anticipate future challenges.

FLIA 2024, Fruit Logistica Awards

In the fruits and vegetables category, the winner chosen through open voting by all visitors was the 'Zucchiolo' by Unica Fresh (Spain), characterized by its versatility and excellent taste, as confirmed by visitors through tastings during the fair days. In the technology category, the chosen winner was the Mirical packaging concept by Koppert (Netherlands), winning the FLIA Technology award, presented for the first time at FRUIT LOGISTICA 2024.

In the technology category, the winning entry was a new format for Mirical, a product by Koppert for biological control against whiteflies and Tuta absoluta, based on nymphs of the bug Macrolophus pygmaeus. The new packaging facilitates release, is user-friendly, improves application precision, and reduces plastic usage by 99%.

Nominees in this category included the optical vegetable trimmer Roto-cut by Wyma Solutions, New Zealand, which results in ready-to-pack root vegetables. In the main image, Jason Gerrie, Managing Director of Wyma's offices in Europe and the UK, stands with the new team.

The equipment fully automates the removal of foliage, crowns, and ends of carrots, turnips, parsnips, etc., before packing or processing. It is the first equipment of its kind to use a combination of optical technology, an intelligent recognition system, and artificial intelligence to individually determine the size and shape of each root and the appropriate cutting point, all within just 0.2 seconds. This solution improves sustainability and operational efficiency with proven real-world labor reductions of over 80%, increased cutting precision, and overall performance, reducing waste by up to 20%.

Other nominees in the technology category included Crop Load Vision (CLV), a mobile application for counting pre-harvested fruits, developed by Croptracker and compatible with iOS mobile devices.

"Aspara to go" by asparagus specialist Hepro addresses the peeling of white and green asparagus, highly valued in Germany, in retail establishments. It is defined as the world's smallest self-service peeler, occupying only 0.34 m².

"Apogeo" by German Bionic is a robotic exoskeleton that combines human intelligence with machine power to enhance the health, safety, and well-being of those engaged in tough and physically demanding jobs.

Cooling, precooling and ripening

Companies in sectors related to temperature and gas management are directing their efforts towards aspects such as improving energy efficiency and making the use of their equipment easier and safer.

Among the companies participating in the Postharvest Community, Absoger manufactures equipment to establish controlled atmospheres with different levels of oxygen for the prolonged conservation of fruit, such as ULO (Ultra Low Oxygen) and XLO (Extreme Low Oxygen), with automated control of the chambers. They also operate in industrial sectors and, in agri-food. They work closely with Clauger, which specializes in industrial refrigeration and air treatment. They build turnkey facilities for ripening, degreening, and conservation in controlled atmospheres.

The Absoger booth, next to Clauger's

BG Door International specializes in airtight doors for refrigerators and ripening chambers tailored to different needs; they also have simple equipment to establish precooling enclosures, whether fixed with curtains or mobile.

Catalytic Generators has achieved a "solution" for the simple ripening of various fruits. Their liquid systems, combined in a simple device to safely produce ethylene, are in demand worldwide. This technology refinement process has been ongoing for over 40 years.

Catalytic Generators and Interko share a commercial organization in Europe under the name Fresh Produce Instruments. From left to right, the individuals in the photo are Steve Page, Vice President of Catalytic Generators; Greg Akins, President of Catalytic Generators and QA Supplies; Anna Zegveld, Senior Business Developer; Narcis Guinart, Project Manager; and Sebastian Becker from Interko

Fruit Control Equipments (FCE), born from research and maintaining significant collaborations with institutes, offers the SWINGLOS® dynamic atmosphere system for horticultural products, as well as ripening and environment sanitization systems.

Isolcell, working since 1958 in controlled atmospheres, is a pioneer in introducing Dynamic Controlled Atmospheres. They manufacture a range of equipment used in both the horticultural sector and other industrial sectors for atmosphere control. They collaborate closely with Apple-related research institutes. Their Amylon equipment facilitates determining ripeness, removing subjectivity from the iodine test; Aeroclean maintains air hygiene, etc.

The Isolcell booth showcases various equipment for establishing and controlling Dynamic Controlled Atmospheres (ADC). In the left corner, there is equipment for assessing the quality of fruits using chlorophyll fluorescence sensors

Interko specializes in ripening chambers and has different models; at Fruit Logistica, they highlighted improvements made to their Ultimo model, increasing the energy efficiency of the ripening chamber, detecting various chambers, and now allowing fruit precooling.

VDH Products, a specialist in temperature, pressure, and relative humidity control, presented several new systems. The MC2-Klima and MC3-Klima controllers received a very positive response and garnered interest from various sectors. There was also significant interest in upgrading old Proba 110 ripening controllers to the new and modern Proba 5 controllers.

Agrochemicals and coatings

Treatments to preserve the quality of fruits and vegetables, both fresh and minimally processed, continue to evolve towards biological origin products or physical methods, and overall, methods that minimize or completely avoid the presence of residues.

Agricoat is a pioneer in solutions to prevent oxidation in minimally processed products, with formulations tailored to apples, guacamole, and many others, as well as products to prevent cherry cracking. This year, the reorganization of stands resulted in a clear improvement in their location and increased visibility.

From left to right: Robert Round, Sales Manager; Simon Matthews, General Manager; and Marino Castillo, who resides in Spain, European Sales Account Manager, also based in Spain

Agrofresh showcased its range of solutions, including decision-support systems such as SmartFresh™ Quality System and FreshCloud™; plant-based products like VitaFresh™ Botanicals, Harvista™, and Uvasys™ for maintaining quality in table grapes.

Citrosol highlighted citrus solutions at their booth, featuring SunSeal® Vegan coatings to control fruit staining, PlantSeal® to prevent water loss, the CitroFy system for improved information management and process control, and the Biocare range for organic production, among other solutions.

Decco Ibérica showcased Deccoshield for pre-harvest application, preserving the quality of treated fruits for better quality and post-harvest lifespan. Their post-harvest range includes waxes, edible coatings, fungicides, and technical solutions like ethylene absorbers and thermographs.

Xeda International offers products and machinery for fruit and vegetable conditioning, conservation systems for potatoes, thermotherapy equipment, and packaging accessories (compostable labels and thermal labels).

Sterilumen, the manufacturer of the Airocide air purifier, was present, showcasing options to clean the air in chambers and other spaces from microorganisms like fungi and bacteria, as well as gases like ethylene and volatile compounds, aligning with their motto, "...with better air, a better life.".

Conditioning

Brimapack specializes in the conditioning of vegetables, offering systems for wrapping round products like head lettuce, cabbages, and broccoli, complemented by bunch tying systems. They also provide field packing equipment equipped with similar systems to those used in warehouses.

Brimapack specializes in different solutions for vegetable packaging

Futura Technology is a company specializing in installations for the selection and conditioning of fruits and vegetables, leveraging years of experience in this and previous ventures. Their calibrators offer a high level of technological precision and productivity.

Omar Papi attends to visitors at his booth at Fruit Logistica 2024

MAF RODA AGROBOTIC provides tailor-made turnkey solutions for a variety of fresh fruits and vegetables, with a focus on innovation and 100% integrated manufacturing of all proposed equipment. The extensive booth at Fruit Logistica showcased a range of equipment, and through the aisle, the systems used in these setups were demonstrated.

Partial view of the MAF Roda Agrobotic booth

Multiscan originated for olive sorting and expanded its solutions to various small fruits, now extending to "regular-sized" fruits. At the fair, they presented innovations in blueberry sorting concerning capacity, cleanliness, and classification quality.

As is customary, the TOMRA Food booth welcomed specialized journalists to explain the new organizational structure, designed to be closer to the customer, and their new solutions based on AI, artificial intelligence, used to address complex issues in food sorting, and Deep Learning.

The TOMRA booth showcased new equipment and their commercial partnership with the company Icoel

Similarly, at trade shows where UNITEC participates, Angelo Benedetti, President and CEO of the UNITEC Group, met with specialized journalists and explained the company's commitment to ensuring that the fruit reaching the consumer is consistently of the highest quality. In their booth, they showcased their latest solutions for the sorting, grading, and packing of various fruits and nuts.

Angelo Benedetti explains the importance, for the producer, of being able to guarantee the quality and consistency of their fruits

Wyma Solutions highlighted its product nominated for the FLIA, offering solutions, primarily for root vegetables, with an extensive range of equipment for the automation of various processes. Their vegetable polishers are among the most recognized equipment.

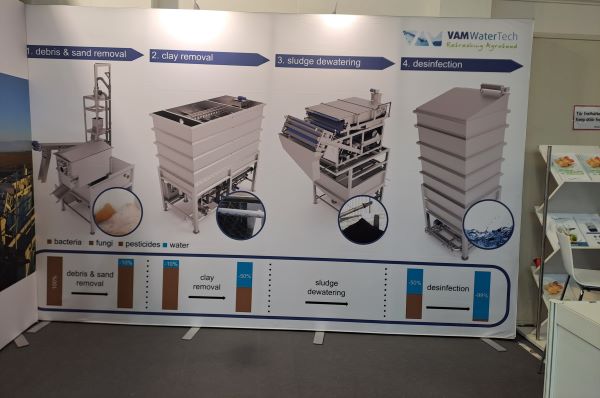

VAM WaterTech addresses an increasingly important aspect of the horticultural business, water management. They focus on purifying water from fruit and vegetable processing, ensuring that warehouses and processors can completely eliminate pesticides and microorganisms from wash water for potatoes, carrots, other vegetables, and fruits.

The modular system from VAM WaterTech removes vegetable residues and sand, followed by clay, water from sludge, culminating in water disinfection

Processing

FAM Stumabo presented improvements made to the new Yuran Capcitec™ among its cutting machines, a device that has delighted pepper processors. The enhancements include a wider belt, providing greater capacity and higher performance. The equipment precisely cuts peppers, leafy vegetables, and other products.

Sven Boen, Sales Manager for EMEA and LATAM, alongside the new Yuran Capcitec™ equipment

URSCHEL showcased its flagship equipment at its booth. The company, specialized in precision cutting, offers solutions to reduce the size of all kinds of fruits and vegetables (and other food products), including root vegetables.

Part of the team attending at the Urschel booth; from left to right, Florence LeLay, Marketing Director of Urschel International; Helena Gómez, Director of Urschel International; and Sergio Gil, Sales Manager of Urschel Spain

Packaging Machinery and Materials

Packaging is a concern due to the scrutiny of plastics; in fact, it was one of the topics discussed at the Fruit Logistica conferences. Pro Food brought together representatives from major European organizations in the fruit and vegetable supply chain for a roundtable discussion where they agreed to emphasize the need for a non-ideological and data-based approach to the effects of packaging fruits and vegetables.

Among exhibiting companies, one noticeable trend is the focus on manufacturers of plastic pallets or bins. Consumer packaging manufacturers offer containers with recycled plastics, lighter weight, adapted to protect the quality of different fruits, as seen with INFIA, and a diversified range based on cardboard and other wood-derived materials, both in packaging and film.

Grup Giró manufactures mesh for packaging fruits and vegetables and is present in all markets. Its trajectory has led to offering packaging with a large surface area to communicate with consumers; later, packages that use minimal plastic raw materials, packages made with cellulose, ... and at Fruit Logistica 2024, the star was its monomaterial packaging, where the metal clip disappears, facilitating recycling.

Giró presented the clip made from the same material as the packaging mesh

Another relevant aspect in terms of recycling and waste disposal is the labels applied to the fruit. Being compostable prevents their presence in the brown container from appearing later as waste.

Euro Label, a company in the same group as Xeda, offers compostable labels.

PacLife, a manufacturer of modified atmosphere packaging and solutions to maintain quality between harvest and storage, highlights a strategic alliance with Alvapack, an Italian company specializing in packaging for the European horticultural sector.

StepacPPC showcased its main ranges of modified atmosphere packaging solutions to extend shelf life - Xtend® for bulk products, Xflow™ for automated bulk packaging, and Xgo™, which includes different types of packaging such as film for lids, vertical packaging with different types of bottoms, preformed bags, etc.

Packaging solutions to extend the shelf life of fruits and vegetables through films that enable the establishment of a modified atmosphere

The ULMA Packaging booth displayed several solutions for packaging fruits and vegetables. The spotlight was on the thermo-sealed tray packaging line for fresh products, the vertical VFFS packaging line for fresh and frozen products, and basic solutions for small and medium processors.

Multiple packaging solutions tailored for fruits and vegetables under the ULMA Packaging WeCare line, which encompasses sustainable packaging and alternative materials.

Services and Instruments

Hispatec specializes in software and AgTech for all stakeholders in the agri-food network. At their booth at Fruit Logistica, they showcased solutions covering both cultivation and warehouse management, along with logistics. They also offer a range of resources, including free workshops from Hispatec Academy that support the digitalization of businesses, post-harvest documentation, ERPagro, cloud backups, etc.

Felix Instruments was present with its portable instruments based on NIR (Near-Infrared Radiation) for the non-destructive assessment of the quality of avocados, mangoes, kiwis, melons, and other fruits. They also offer portable gas meters.

In the foreground, Hunter Weber, Marketing Coordinator at Felix Instruments

T.R. Turoni's booth is a classic at Fruit Logistica, located in the Italy zone, but its extensive range of instruments reaches a global audience. Their universal calibrator, introduced in the 2023 edition of the fair, has been well-received this year, along with instruments to assess the firmness of small fruits such as cherries and berries.

Varieties of Plant Material

Plant varieties, both for vegetables and fruits, are the foundation for consumer acceptance, farmer success, and an efficient distribution chain, minimizing losses due to poor post-harvest performance.

Sakata, Semillas Fitó, and Rijk Zwaan were present at Fruit Logistica showcasing their varieties and innovations.

Rijk Zwaan highlights its "Retail Center" at the booth, where they analyze consumer behavior regarding product offerings on the shelf.