Actualidad

Good results fo a modified atmosphere film on Agaricus bisporus postharvest

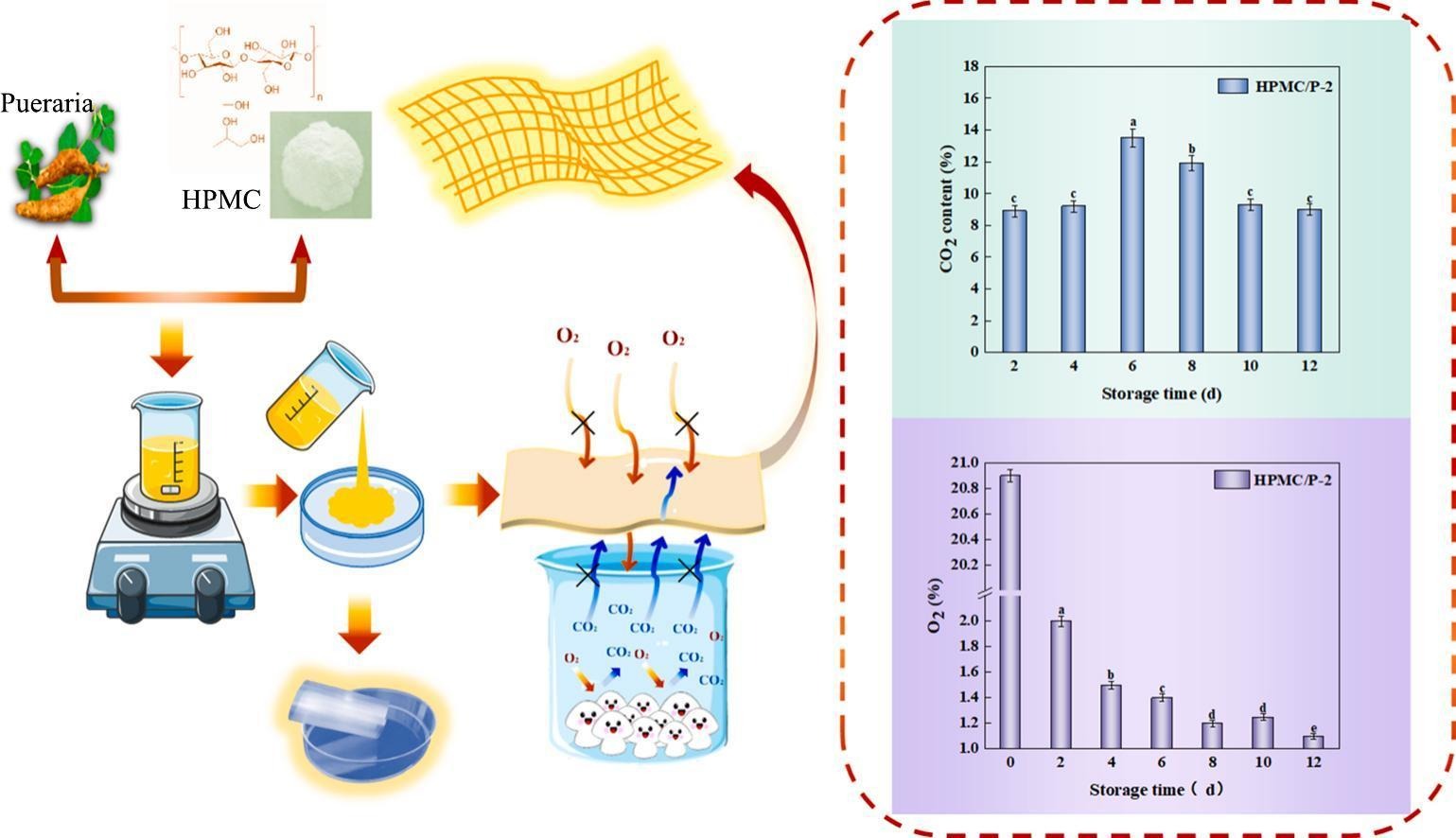

The modified atmosphere film is based on hydroxypropyl methylcellulose and starch obtained from Pueraria, a plant from the Fabaceae family

Redaccion

Resource depletion and environmental pollution owing to the use of petroleum-based packaging materials have recently become increasingly prominent, which has prompted the food packaging industry to make great adjustments.

Cellulose, as a type of straight-chain d-glucose molecular polymer, is connected by hydrogen bonds and β-1,4-O bonds. However, the low flexibility and insolubility of cellulose have limited its greater space for development in the commercial field.

Developing a new generation of cellulose products

Currently, researchers of materials science, nanotechnology, biology and chemistry fields are working together to develop a new generation of cellulose products with new and improved properties.

Hydroxypropyl methylcellulose (HPMC) is a water-soluble derivative of cellulose that can effectively solve the aforementioned problems. Nevertheless, a higher number of hydroxypropyl side groups would decrease the overall crystallinity of the polymer, leading to an increase in permeability.

This is not beneficial for the formation of films with good barrier properties.

Low permeability starch

This problem can be solved by introducing low-permeability starch in the film.

Being a thermoplastic material, pueraria starch (Pueraria belongs to the Fabaceae) and cellulose have the same glucose unit. Under the excellent mechanical performance and good appearance of HPMC film, the introduction of puerstarch blend film is conducive to the formation of a uniform and stable mixing system, which can improve the gas barrier capacity of the film, but also effectively improve the thermodynamic performance of the film.

Of note, starch is semi-permeable to CO2 and resists O2 permeability, thereby creating good conditions for the formation of a spontaneous atmosphere control system of the film. However, studies on the blending of HPMC/P root to form a film are lacking.

Improving the gas composition inside the packaging

As a new fresh-keeping technology for extending the storage period of fruit and vegetables, bio-based packaging can effectively regulate the water and nutrient migration rate and delay aging by improving the gas composition inside the packaging. This is similar to the preserving technology of a modified atmosphere.

Traditional modified controlled atmosphere equipment is expensive, with their commercial application being limited. Therefore, the development of new packaging technology is urgent and critical.

To meet the requirements of maintaining relatively low respiration of fruit and vegetables, a simple modified atmosphere environment can be formed by controlling the effective coordination between packaging and fruit and vegetables. The dynamic balance of a gas environment is maintained through the respiration of products and film permeation.

Agaricus bisporus postharvest characteristics

Agaricus bisporus (white mushroom) is among the most widely cultivated and consumed mushrooms globally. Postharvest white mushrooms are susceptible to aging and deterioration due to their vigorous respiration and lack of cuticle, thus affecting their commercial value.

Highly tolerant to CO2

Our studies have shown that white mushroom is highly tolerant to CO2, and a 20 % CO2 modified atmosphere combined with a low-temperature environment can increase the storage period of Agaricus bisporus for up to 30 days.

Modified atmosphere packaging (MAP) has currently exhibited great potential in market applications. Therefore, adopting a type of MAP to prolong the storage life of white mushrooms is of great significance. Studies have investigated the use of MAP film for white mushroom storage.

Studies on MAP film

Hay et al. improved the HPMC film by incorporating amyllose-palmitate sodium inclusion compound, and the prepared blend film had certain barrier properties for water vapor and oxygen.

Even, Caleb et al. used microperforations in bio-based films to regulate the gas environment inside the package.

However, the gas regulation properties of packaging are not explicitly proposed in the above literature. Therefore, the HPMC/P blend film prepared in this study is a packaging film with gas conditioning effect, which has some novelty.

At the same time, compared with other gas-controlled packaging films, our materials and preparation process are simpler without more bioactive agents to assist the process.

Focus of this study

This study focused on overcoming the shortcomings of the existing film preparing process, developing a gas-regulated respiratory film through a simple process, improving the air permeability of the film, maintaining the O2 concentration in the package as low as possible, establishing a higher CO2 gas environment, and thus effectively preserves white mushrooms.

An HPMC/pueraria powder blended film was developed in this study.

By improving its barrier properties, the environment of the modified atmosphere package was spontaneously adjusted to delay the aging of postharvest white mushrooms.

The mechanical properties, barrier properties and internal gas environment of the biofilms were evaluated.

The thermal stability, microstructure and biocompatibility of the films were systematically characterized through Fourier-transform infrared (FTIR) spectroscopy, scanning electron microscopy (SEM) and thermogravimetric analysis (TGA).

Meanwhile, the blended film was applied to package and preserve white mushrooms. This study is expected to provide new insights into the application of spontaneously modified atmosphere bio-based packaging for freshness preservation.

Conclusions

In general, the composite film with excellent properties was successfully prepared through a simple process by using pueraria starch and HPMC.

The HPMC/P-2 film exhibited the highest mechanical properties and excellent barrier properties.

Meanwhile, the O2 concentration inside the HPMC/P-2 package was 1–2 % and the CO2 concentration was 8–13.8 %, which is suitable gas concentration environment for maintaining the good quality of white mushrooms.

Compared with other mixed films, hydroxypropyl methylcellulose (HPMC)/pueraria (P)-2 showed better mechanical properties, barrier properties and thermal stability energy. Applying the HPMC/P-2 film for preserving white mushrooms can spontaneously adjust the internal gas environment.

Moreover, the O2 concentration in the package remained stable at 1–2 %, and the CO2 concentration was between 8 % and 14 %.

The film can effectively reduce the respiration rate of white mushrooms, inhibit enzymatic browning, maintain their good color and texture, and delay their aging.

In conclusion, the HPMC/P-2 film can be used not only for fruit and vegetables preservation but also provide theoretical basis for sustainable food packaging.

Graphical abstract of the paper

Graphical abstract of the paper

Sources

Xin Jiang, Lei Feng, Jiali Han, Ling Li, Jia Wang, Haipeng Liu, Hiroaki Kitazaw, Xiangyou Wang. (2024). Preparation of hydroxypropyl methylcellulose/pueraria-based modified atmosphere film and its influence on delaying the senescent process of postharvest Agaricus bisporus. International Journal of Biological Macromolecules. https://doi.org/10.1016/j.ijbiomac.2024.129611

Picture

Cómo se deben embalar los champiñones para su distribución y exportación, http://flejadoras.reisopack.com/2015/05/como-se-deben-embalar-los-champinones.html