TOMRA Food

Conditioning

TOMRA Food strengthens its AI technology offering and highlights Valencia HQ at Fruit Attraction 2024

TOMRA Food participated in the opening day of the 25 th edition of Fruit Attraction, the premier international trade fair gathering the leading companies in the fruit and vegetable sector, held from October 8-10 at IFEMA (Madrid, Spain). At the event, the company showcased the latest advancements in its LUCAi™ AI solution and hinted that the technology will shortly be available for the citrus category, and introduced the benefits of its new regional structure with a new headquarters in Valencia. This reorganization strengthens customer proximity and enhances its ability to deliver comprehensive technical and sales support

TOMRA Food used the highly-anticipated 25th Fruit Attraction event in Madrid to unveil its renewed investment and support for the global fruit industry. With a new headquarters in Valencia and the chance to take a sneak peek at the soon-to-be-released LUCAi application for citrus fruits, plus the TOMRA 5A, our bulk sorting solution for whole products like potatoes, carrots and peppers.

David del Castillo, Regional Sales Director for Southern Europe, said:

“The food sector is experiencing continuous growth, driven by clear factors such as demographics. In particular, the fruit and vegetable sector has seen a significant surge recently. Market players have had to face new challenges to deliver quality without sacrificing speed. This is largely due to increased awareness among younger generations about the importance of healthy eating, a trend that older generations are also adopting, along with the instant gratification consumers now expect from online shopping”.

David del Castillo said:

“The citrus industry clearly needs more efficient and user-friendly sorting systems. Given the wide variety of citrus fruits – oranges, mandarins, lemons, clementines, limes, grapefruits – and the numerous varieties within each type, LUCAi™ Citrus will play a pivotal role. While it has required substantial effort from TOMRA, we are now in the final stages and will soon demonstrate the remarkable results we can achieve. We are confident this will be a game changer in the market and redefine the way those looking to stay competitive will work”.

Fruit Attraction attendees among first to experience LUCAi™ for citrus

The new LUCAi™ citrus application will integrate TOMRA’s latest advancements in AI technology based on Deep Learning. Developed by a team of leading scientists, engineers, researchers and industry experts, LUCAi™ uses pre-trained models to teach computers how to process data, including complex image patterns to achieve unprecedented sorting accuracy across an expanding range of fruits. It follows several pioneering launches. In 2018, TOMRA Food launched LUCAi for blueberries on the KATO 260 blueberry grader, which was the world’s first deep learning program for fruit sorting. LUCAi™ deep learning for apples followed on the TOMRA Spectrim machine. In 2023, TOMRA added a cherries application to the LUCAi™ portfolio, which is now available on the InVision2, and there are other categories currently being worked on.

David del Castillo asserted:

“A key pillar of our strategy is maintaining our technology leadership. We want to share with the industry the outstanding results our customers are achieving by integrating LUCAi™ Artificial Intelligence into their sorting systems for blueberries, apples, cherries, and soon citrus, along with other commodities. There are already over 500 processing lanes now powered by LUCAI™, and the results have been outstanding in terms of performance, improved batch quality, and greater ease of use for operators.”

“We have already installed the first trial units in all citrus growing regions in both the Northern and Southern Hemispheres. Specifically, in Spain, we have two units operational for the upcoming citrus season and expect strong demand for this solution in several countries".

TOMRA Food welcomes customers, partners, and investors to new Valencia HQ

David del Castillo also emphasized the positive results the company is achieving with its new regional structure, which enables closer relationships with customers.

“The new regional organization enables us to respond to our clients’ needs more quickly and efficiently. While we maintain our global presence, we engage with our customers on a local level. A key component of our EMEA strategy is the TOMRA Food Center in Valencia, which celebrated its first anniversary in September. This facility enables us to eliminate intermediaries and interact directly with customers in Spain, addressing their commercial and technical support needs. Additionally, we offer training programs for new and existing clients, as well as a demonstration hall where we can showcase the advantages of our equipment firsthand.”

Roberto Ricci, Director Channel Partner Management at TOMRA Food, underscored the effectiveness of the partnership with ICOEL, stating:

“ICOEL has emerged as a strategic partner in advancing TOMRA’s business development. They recently completed a significant expansion of their facilities in Fondi, Italy, increasing their production capacity, R&D capabilities, and spare parts inventory. Together, we have successfully completed several installations for citrus, apples, and stone fruits, particularly in Italy and Turkey. ICOEL’s on-site support for our engineers was crucial for the validation and implementation of LUCAi™ for cherries last summer. Thanks to this work, we have already secured orders for new LUCAi™ upgrades for cherry lines in Italy for the upcoming season, and we plan to replicate this success for the upcoming citrus season.”

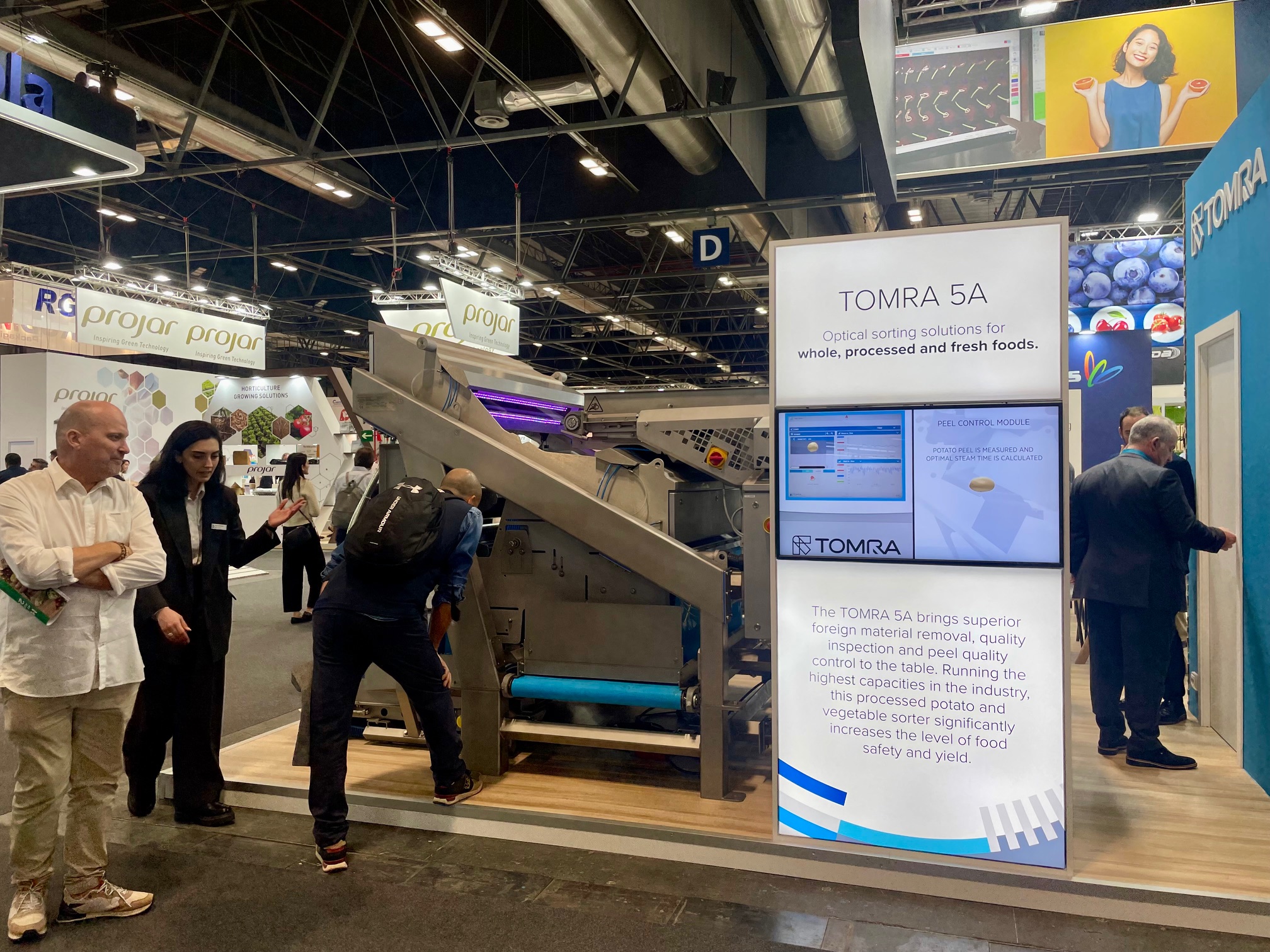

TOMRA 5A: efficiency and precision

The TOMRA 5A is a high-capacity sorting and grading machine, designed for large volumes, enabling the sorting of food while effectively removing a wide array of foreign materials. Equipped with pulsed LED technology, cameras and near-infrared (NIR) sensors, it guarantees exceptional detection and removal of defects. Initially focused on the potato sector, its applications have expanded to include carrots, peppers, and other vegetables due to increasing market demands for quality and the impracticality of manual sorting processes for large quantities. The TOMRA 5A also has a pre-sorting application for citrus fruits.

David del Castillo affirmed:

“The TOMRA 5A is a key component in the production line for eliminating impurities that could compromise food safety and removing quality defects”.

TOMRA Food’s present and future areas of focus

In light of market forecasts, TOMRA Food has already established its strategic focus. As David del Castillo explained:

“Sustainability will be an increasingly important priority in the industry, and TOMRA is fully committed to the circular economy. This commitment is in TOMRA’s DNA, which is reflected in our motto #EveryResourceCounts. Climate change can impact fruit production, affecting both prices and availability. To mitigate potential price increases, maximizing the efficiency of packing plants is essential, and TOMRA, with its technology, plays a crucial role in this effort. We will focus on specialized and premium products due to market segmentation; we will adapt to regulatory changes regarding food safety, labeling, and sustainability – areas in which TOMRA is already well-

aligned.”

About TOMRA Food

TOMRA Food designs and manufactures sensor-based sorting machines and integrated post-harvest solutions transforming global food production to maximize food safety and minimize food loss, by making sure Every Resource Counts TM .

The company has more than 13,800 units installed at food growers, packers and processors around the world for Confectionery, Fruit, Dried fruit, Grains and Seeds, Potatoes, Proteins, Nuts, and Vegetables.

These solutions include advanced grading, sorting, peeling and analytical technology to help businesses improve returns, gain operational efficiencies, and ensure a safe food supply.

TOMRA Food operates centers of excellence, regional offices and manufacturing locations within the United States, Europe, South America, Asia, Africa and Australasia.

Follow @TOMRA.Food, X @TOMRAFood, Instagram @TOMRAFood, LinkedIn at TOMRA Food and YouTube at TOMRA Food.

TOMRA Food is a division of TOMRA Group. TOMRA was founded in 1972 that began with the design, manufacturing and sale of reverse vending machines (RVMs) for automated collection of used beverage containers.

Today, TOMRA is leading the resource revolution to transform how the planet’s resources are obtained, used and reused to enable a world without waste. The company’s other business divisions are TOMRA Recycling and TOMRA Collection.

TOMRA has approximately 105,000 installations in over 100 markets worldwide and had total revenues of about 14.8 billion NOK in 2023. The Group employs 5,000 globally and is publicly listed on the Oslo Stock Exchange. The company headquarters are in Asker, Norway.

For further information about TOMRA, visit www.tomra.com.