TOMRA Food

Conditioning

TOMRA LUCAi® technology transforms Freshco’s apple grading, tackling stem splits and punctures with precision

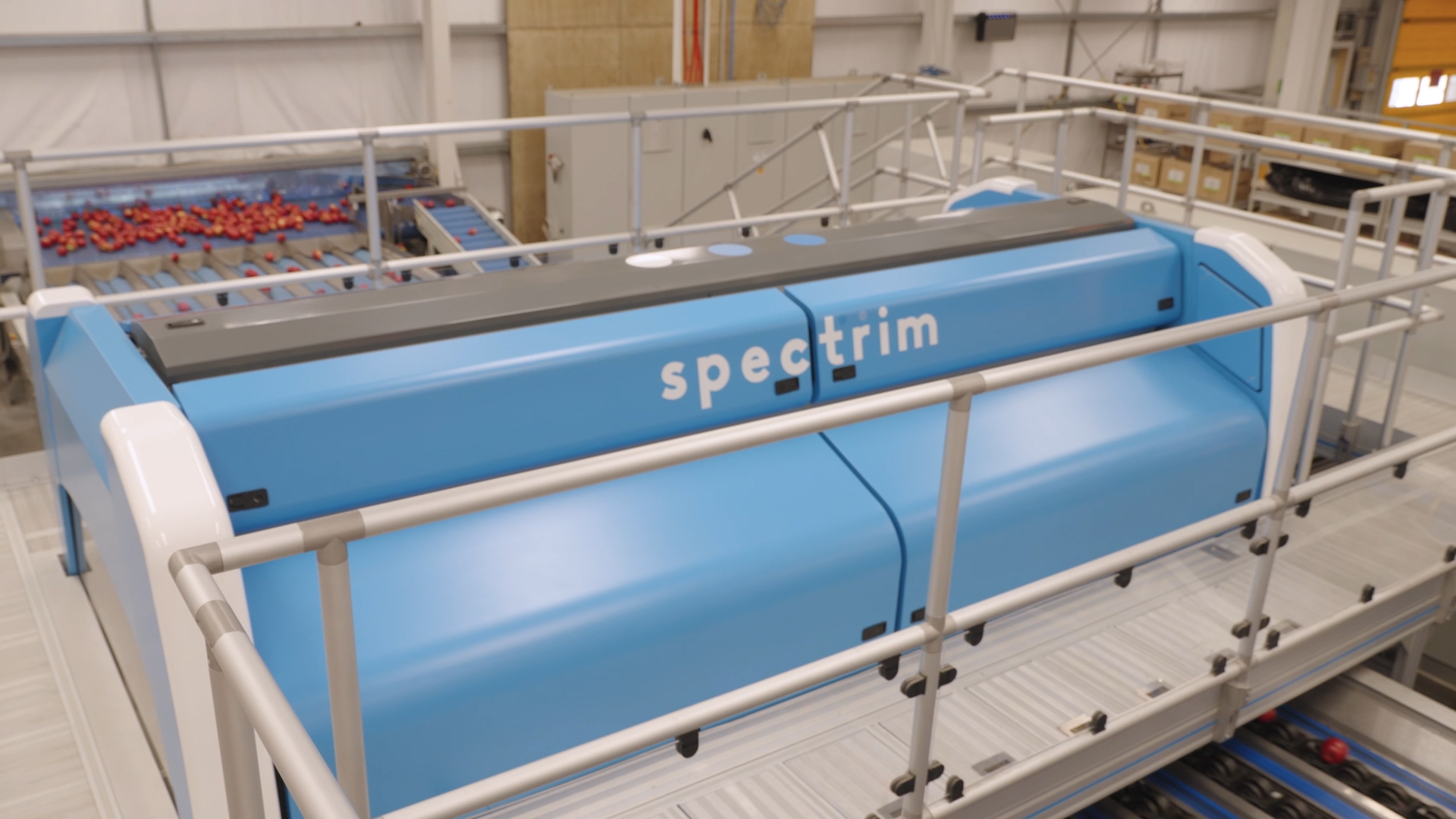

Leading apple grower and exporter Freshco dramatically improved the efficiency and accuracy of the grading process at their packing operation with TOMRA’s Spectrim LUCAi® upgrade package

Founded in 1989, the Fresh Fruit Company of New Zealand (Freshco) is a leading fruit and vegetable exporter based in Auckland, New Zealand, with orchards, packing houses, cool stores and offices in key growing locations throughout the country. It grows and sources high-quality apples that meet the stringent quality and safety requirements of its demanding customers around the world.

Freshco recently implemented the new LUCAi® upgrade package on its TOMRA Spectrim grading platform and found it to be a game-changer. It allows Freshco to not only tackle laborious stem split and puncture defects, but to move seamlessly between varieties without making adjustments.

LUCAi® identifies apple splits and punctures with precision out-of-the-box

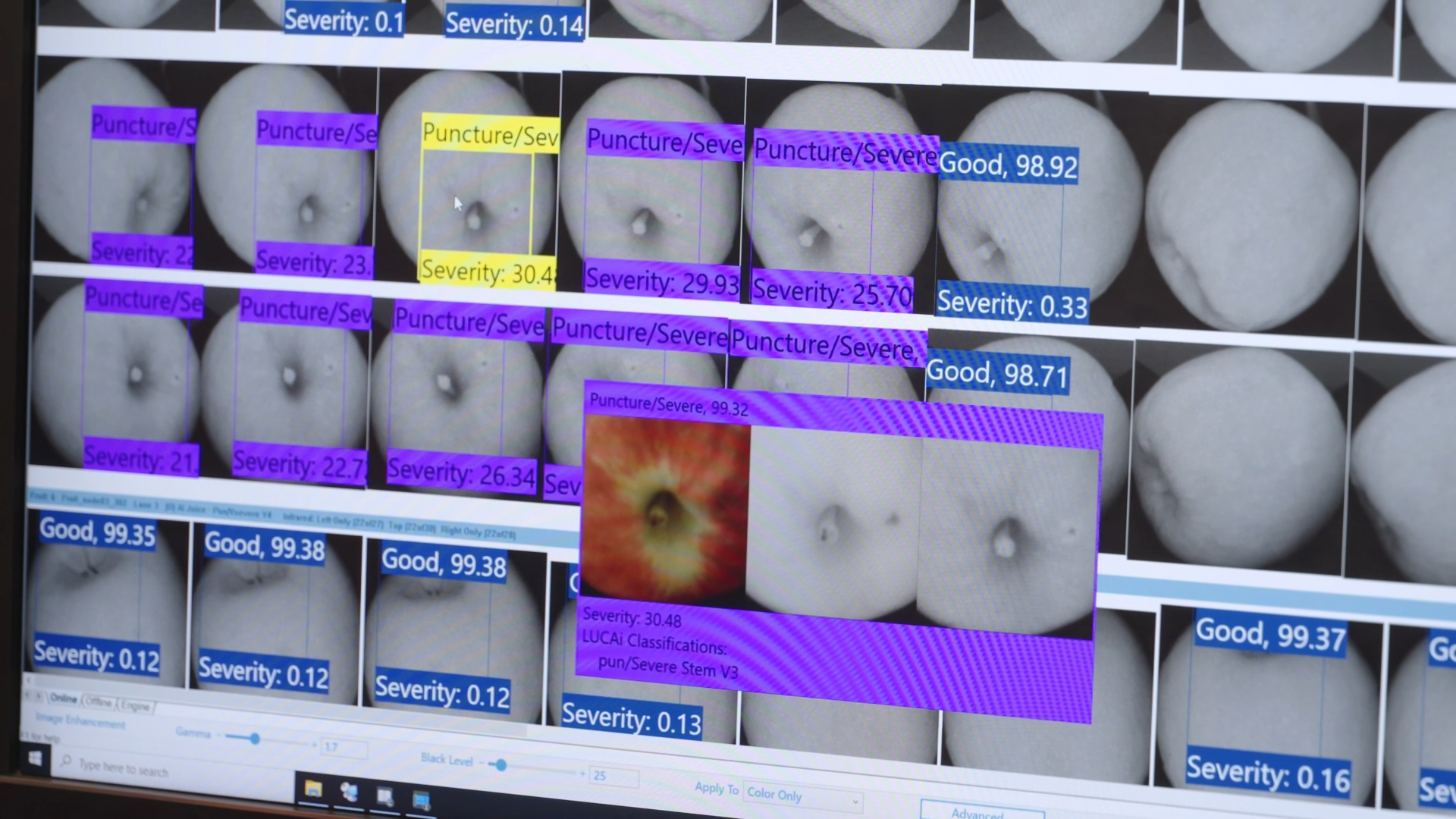

The LUCAi® upgrade package for Spectrim includes Deep Learning models, pre-trained by vast datasets captured from TOMRA machines across the world and precisely labelled by TOMRA’s Data Science Team. With LUCAi®, the Spectrim X assesses thousands of high-resolution, multi-channel fruit images every second and cross-references them with these datasets to make grading decisions. It is able to precisely detect and classify even the trickiest apple defects, such as splits and punctures across multiple varieties.

Robin Mudgway, Technology & Machinery Manager at Freshco, explains:

“The main defects are around the stem area. The splits are really hard to get around the stem, and you’re forever working on the splits and punctures. With LUCAi® we get a model from TOMRA and then we just put our own severity and confidence into it.”

LUCAi® enables the operator to seamlessly switch varieties without slowing down the process. Glen Kaunds, TOMRA Food Senior Application Engineer, says:

“You can use a model that is doing stem split and stem punctures, for example, on Gala apples. Then you can move to another variety that has the same defect and it just works. You don’t have to make any adjustments to it”.

Spectrim with LUCAi® allows customers to easily adjust the severity of grading parameters – something which previously had to be done by experienced operators – to cater to seasonal dynamics and market preferences.

“We deal with a lot of Royal Gala and Breeze apples, and they tend to have a lot of splits. LUCAi™ made it really easy to control that. Production was not slowed down at all like it would have in the past. This means that throughput stays at a good pace within the shed.”

Spectrim with LUCAi® is very easy to operate thanks to the user-friendly interface. Robin Mudgway concludes:

“The new User Interface is really beneficial for tracking grades. You can see more data and when you make changes, you can see the percentage change you’re making. The return on investment is a no brainer because your production’s not slowing down.”

About TOMRA Food

TOMRA Food designs and manufactures sensor-based sorting machines and integrated post-harvest solutions transforming global food production to maximize food safety and minimize food loss, by making sure Every Resource Counts TM .

The company has more than 13,800 units installed at food growers, packers and processors around the world for Confectionery, Fruit, Dried fruit, Grains and Seeds, Potatoes, Proteins, Nuts, and Vegetables.

These solutions include advanced grading, sorting, peeling and analytical technology to help businesses improve returns, gain operational efficiencies, and ensure a safe food supply.

TOMRA Food operates centers of excellence, regional offices and manufacturing locations within the United States, Europe, South America, Asia, Africa and Australasia.

Follow TOMRA Food on Facebook @TOMRA.Food, X @TOMRAFood, Instagram @TOMRAFood, LinkedIn at TOMRA Food and YouTube at TOMRA Food.

TOMRA Food is a division of TOMRA Group. TOMRA was founded in 1972 that began with the design, manufacturing and sale of reverse vending machines (RVMs) for automated collection of used beverage containers.

Today, TOMRA is leading the resource revolution to transform how the planet’s resources are obtained, used and reused to enable a world without waste. The company’s other business divisions are TOMRA Recycling and TOMRA Collection.

TOMRA has approximately 105,000 installations in over 100 markets worldwide and had total revenues of about 12 billion NOK in 2022. The Group employs 5,000 globally and is publicly listed on the Oslo Stock Exchange. The company headquarters are in Asker, Norway.

For further information about TOMRA, visit www.tomra.com.