Unitec Group

Conditioning

UNITEC: Innovation for 100 years and counting

At Fruit Logistica UNITEC Group presents its latest solutions for the fruit and vegetables industry. Research and experimentation continue incessantly, in strong connection with the market

It was 1924 when the first sorters by Dalle Vacche appeared in Massa Lombarda. In this historical company, through the integration of new entrepreneurial experiences, UNITEC has its roots. It immediately stands out for the development and application of new, non-destructive technologies for quality selection of fruit and vegetables, with the goal of providing concrete answers to satisfy the needs of fruit and vegetables companies. The company’s mission is explicitly stated in the payoff: “we work for your results”, which expresses a strong connection with Customers’ needs, constantly fueled by existing knowledge and driven towards finding new answers, to encourage market progress. This journey, started in the Twenties with Dalle Vacche company, characterized by research, analysis, experimentation and guided by a great passion for concreteness and a continuous pursue of perfection, where Customer results are the ultimate goal.

100 years of constant innovation in the sorting of internal and external quality of fruit and vegetables, as well as in all the other handling stages of packing houses, constantly engineering the most innovative technologies for the development of exclusive UNITEC solutions. An important milestone which frames the Group participation at the Berlin’s exhibition. A first turning point that propels UNITEC towards the future, following its vocation for innovation which is currently represented by the opportunities offered to the produce industry by robotics, from the field to the sales outlet, through the packing houses. UNITEC has already successfully sorted more than 50 types of fruit and vegetables and it is now getting ready to face the next challenges, leveraging the know-how built over the years.

Angelo Benedetti, President of UNITEC, states:

“One hundred years is a timeframe that could make one feel old, but this is not our case. The average age of the UNITEC Team is 35 years and the inspiration and the motivation that our Customers around the world give us every day, by trusting us, are a long life elixir for us. We frequently manage to build partnership paths that bring concrete benefits to Customers, and this is the positive energy that nourishes us, allowing us to look forward to the next 100 years. Thank you! Thank you! To every Customer who trusted us over these 100 years”.

At Fruit Logistica 2024, UNITEC Group is showcasing some of its solutions on its three booths, dedicated to its various fields of specializations.

UNITEC – Hall 4.1 / A-10

- UNI Smart Tray Filler

Automatic filler which allows to pack different varieties of fruit such as peaches, nectarines and apples in trays or in trays inside crates. Fruit gathering and placing in trays thanks to an innovative robot with a pick and place function, that can adjust the coordinates of gathering/placing based on the size and format of the package in handling.

- UNICAL 200 Cherry: Cherry Vision 3.5 Ai

Cherry Vision 3.5 Ai is UNITEC innovative technological solution that, thanks to the use of state-ofthe-art Artificial Intelligence models and to the strong connection of UNITEC to the global cherry sector, allows to accurately detect recent cuts and cracks on cherries. Cherry Vision 3.5 Ai is the solution, entirely developed inside UNITEC Research and Development Department, which can help Packing Houses especially in very rainy seasons.

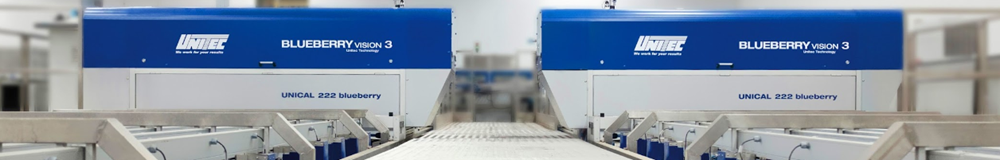

- UNICAL 222 Berry

Also exhibited in UNITEC booth is the technology for blueberry quality selection, equipped with Blueberry Vision 3 and UNIQ Blueberry. These systems can completely scan every blueberry, for even better, precise and reliable external and internal quality selection, to enhance the organoleptic characteristics of this fruit while fully preserving its integrity.

- UNIQ solutions for the internal quality selection dedicated to every single fruit

Many innovations on internal quality selection systems, all entirely created by the company’s R&D department, dedicated to specific fruit of the UNIQ range (UNIQ Kiwi, UNIQ Apples, UNIQ Peach, UNIQ Plum, UNIQ Blueberry, UNIQ Cherry, UNIQ Apricot, UNIQ Melon, UNIQ Pomegranate, UNIQ Cherry Tomato, UNIQ Pears, UNIQ Avocados, UNIQ Onions, UNIQ Dates, etc.).

- UNICAL 222 HAZELNUT

UNITEC has also developed solutions for hazelnut sorting: Hazelnut Vision system provides great benefits to the handling process and quality selection of hazelnuts (with or without shell, raw or roasted), detecting their defects besides their shape, size and color.

UNISORTING – Hall 4.1 / A-20

- UNI INTELLIGENT PACK DATES

Robotic solution to pack dates inside punnets. This totally automatic system increases efficiency in the packing stage and allows great cost optimization by drastically reducing labor costs.

- UNI FLOW GENTLE PACKER

Patented solution by UNISORTING that maximizes efficiency and automatic packing capacity of apples through a continuous and gentle transfer of fruit inside trays. All this while preserving the integrity of every fruit, thanks to the use of extremely gentle suction cups individually dedicated to each apple. UNI ROBOTICS – Hall 4.1 / B-10

- UNI SMART PAL ROBOT (robotic cell for high efficiency automated palletization)

This solution can maximize efficiency and capacity of the back-end phase. Thanks to anthropomorphic robots, it allows to palletize numerous formats automatically with no mechanical regulations. It can compose multiple types of mosaics, including different patterns on the same pallet, to improve stability.