Unitec Group

Conditioning

UNITEC: Listening and Dialogue at the heart of Fruit Logistica 2025 - Hall 4.1, stand A-10 / A-20 / B-10

Artificial Intelligence and robotics lead the innovations presented by the three divisions of the Group at the Berlin trade show

Connection to the produce industry, operations across more than 50 types of fruit, development and continuous updating of entirely “home-made” technologies: these are the distinctive features that give substance to its mission “We Work for Your Results”.

Nour Abdrabbo, Global Sales Director of the UNITEC Group, introduces the participation of the three divisions of the company to the Berlin kermesse:

“Fruit Logistica represents an excellent opportunity for us to listen to the needs of the fruit and vegetables industry and to engage directly with its key players. It is also an occasion to showcase our innovations dedicated to Packing Houses all over the world”.

“The ongoing dialogue with our current and potential Customers about their present and future needs is the ‘nourishment’ of our innovation and allows us to strengthen our connection with the fruit and vegetable industry, which is the mantra of UNITEC - a fundamental value embodied in our Brand’s pay-off: ‘We Work for Your Results’”.

“Our enthusiasm in tackling new challenges – from the impact of climate change, which increases qualitative variability of harvests, to international instability, which extends transit times to destination markets - stems from our passion for research and our dedication to Customer service”.

The President of UNITEC, Angelo Benedetti, emphasizes:

“Our determination to achieve results, in turn, originates from the awareness that we can bring into play one hundred years of experience on more than 50 types of fruit and an unparalleled Research and Development division in the industry. This allows us - with UNITEC and UNISORTING - to develop in-house all our solutions for external and internal quality selection of fruits. Alongside these solutions, we integrate automation with robotization of the upstream and downstream stages designed by UNI ROBOTICS to increase process efficiency and reduce labor costs and needs”.

In Berlin, the Group presents several innovations across all these fields, described below, with a focus on the increasingly advanced integration of the latest generation of Artificial Intelligence, to perfect and customize system performance. This is made possible by solid foundations in hardware and in vision technology that UNITEC has developed in-house and, because of this, has constantly improved over time.

Innovations of the Unitec Group showcased at Fruit Logistica 2025, Hall 4.1, stand A-10 / A-20 / B-10

UNITEC TECHNOLOGIES

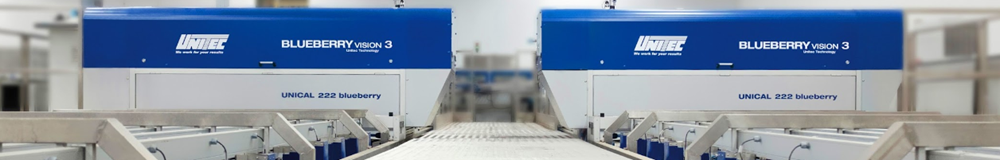

Blueberries Sampling Machine UNICAL 222

Blueberries sampling line with ultra-compact design. Thanks to its reduced size, it can be easily used in a pre-sorting sampling context, with the possibility of providing a preview of the characteristics of product batches, making it easier to check the average quality of the fruits entering the Packing House and therefore helping to define the best sorting options and how to best use the product, according to the needs of the final Client.

Thanks to the integrated high technology for external quality selection with Blueberry Vision 3 and for internal quality selection with UNIQ Blueberry - which allows Brix degree and acidity detection too - it can also be used to develop new varieties ("breeding") to collect data more rapidly and efficiently, which is useful to validate the external and internal characteristics of the fruit.

UNICAL 200 Cherry sorter with Cherry Vision 3.5 AI

Cherry Vision 3.5 AI is the innovative technological solution of UNITEC that, thanks to the use of cutting-edge Artificial Intelligence models allows accurate detection of recent cuts and crackings on cherries. Cherry Vision 3.5 AI is the solution, entirely developed within the UNITEC Research and Development department, that can help Packing Houses especially in particularly rainy seasons.

Besides, Cherry Vision 3.5 AI allows:

- identifying soft fruits with reliability, thanks to the inclusion of UNI AI SOFT technology;

- detecting with very high precision the external defects in stemless fruit and in fruit with a noticeable suture line;

- sort each cherry with precision in case of fruit with irregular, not spherical shape and with flowers.

UNICAL 10.0 sorter with Avocados Sort and UNIQ Avocados

Solution designed to allow the handling of different types of fruit, even with different sizes and shapes, such as avocados, oranges or flat peaches. The fruit is sorted in a non-invasive way and without causing any mechanical damage to the product. The presented solution is the one to handle avocados.

Internal quality selection systems – “UNIQ”

Many new developments in the internal quality detection systems, entirely developed by the UNITEC R&D Department and dedicated to specific fruits of the UNIQ range, of which this year we present: UNIQ Blueberry, UNIQ Cherry Tomato, UNIQ Kiwi, UNIQ Peach, UNIQ Mandarin, UNIQ Plum, UNIQ Cherry, UNIQ Apricot, UNIQ Orange, UNIQ Pomegranate.

UNICAL 222 technology with Hazelnut Vision 4.0 AI

UNITEC has introduced innovations again into the solutions for hazelnut sorting with the Hazelnut Vision 4.0 AI system, which uses Artificial Intelligence models developed in-house, in order to sort with precision hazelnuts with or without shell, raw or roasted. The system detects defects more accurately, besides shape, size and color.

UNISORTING brand of UNITEC TECNOLOGIES

UNI SMART TRAY FILLER – Solution for automatic packing

Automatic filler which allows to pack different varieties of fruit such as peaches, nectarines and apples in trays or in trays inside crates. Fruit gathering and placement in trays is performed thanks to a multiheaded robot with a “pick and place” function, that can adjust the coordinates of gathering/placement based on the size and format of the package being handled. Incoming fruits are channeled and singularized on a transport system: thanks to the integrated vision system, they are correctly oriented and prepared to be collected. This technology is characterized by high capacity (number of fruits per minute) and optimization of the use of space.

UNICAL 244 DATES sorter with Dates Sort 3 and UNIQ Dates

Electronic sorter dedicated to the handling of small and medium-sized products, such as damson plums, small tomatoes, jujubes, olives, radishes, chestnuts, walnuts and dates (the solution on display will be dedicated to the latter fruit).

Advantages:

- Cost reduction compared to manual handling;

- Possibility to use unskilled labor;

- Objective increase of efficiency in handling and in product quality;

- Cost-effectiveness of electronic and mechanical maintenance;

- High performance thanks to cutting-edge, easy to use software.

Internal quality selection systems – “UNIQ”

Many new developments in the internal quality detection systems, entirely developed by the UNITEC R&D Department and dedicated to specific fruits of the UNIQ range, of which this year we present: UNIQ Apples, UNIQ Pears, UNIQ Avocados, UNIQ Dates, UNIQ Onions.

UNI ROBOTICS brand of UNITEC TECHNOLOGIES

UNI SMART PACKER - Robot for clamshell and heat-sealed tray packing

UNI ROBOTICS brand of UNITEC, introduces an innovative packing solution, a stage where the use of robotics is becoming more and more common. Designed for clamshells and heat-sealed trays, UNI SMART PACKER ensures that the lid remains closed and minimizes the use of labor in repetitive and high-intensity tasks, guaranteeing constant production at the same time. This system combines efficiency and gentleness, protecting the package during handling. Besides, its flexibility allows switching rapidly from one size to another and adapting to different sizes of clamshells and heat sealed trays.

ROBOTIC CELL for depalletization, deposit and palletization for crates

UNI ROBOTICS brand of UNITEC introduces an innovative solution that, thanks to the use of robotics, can guarantee complete automatization, eliminating the use of labor and improving the efficiency of the entire production line. This innovative solution analyzes the crates on the pallet and calculates the optimal gripping point to ensure their correct handling and to protect the product inside them. The robotic cell is also equipped with a system that automatically scans the collection area, adapting to changes in the shape, position and height of the crates, through the intuitive graphic interface shown on the display.