Wyma Solutions

Conditioning , Cooling and CA , Packaging , Processing

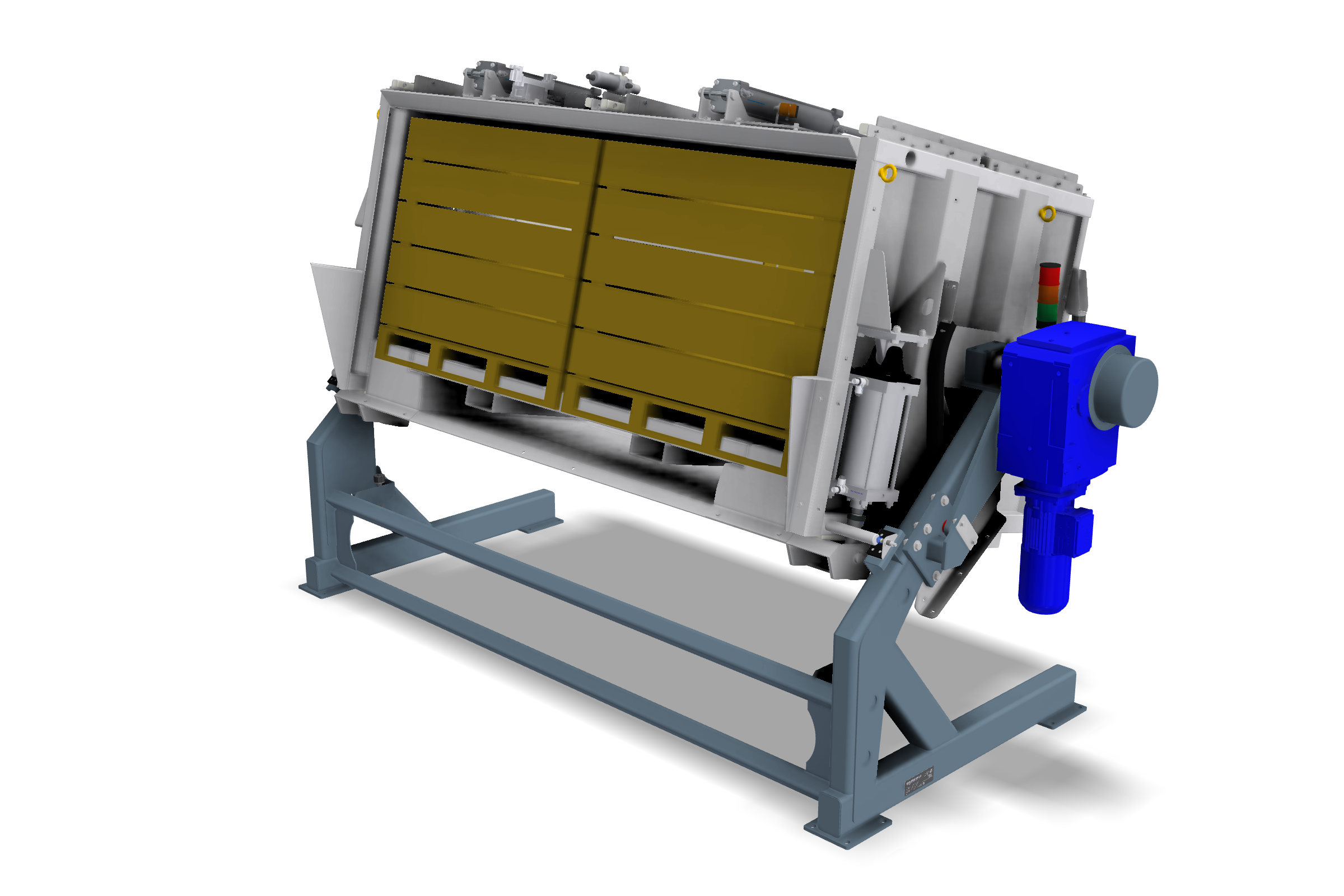

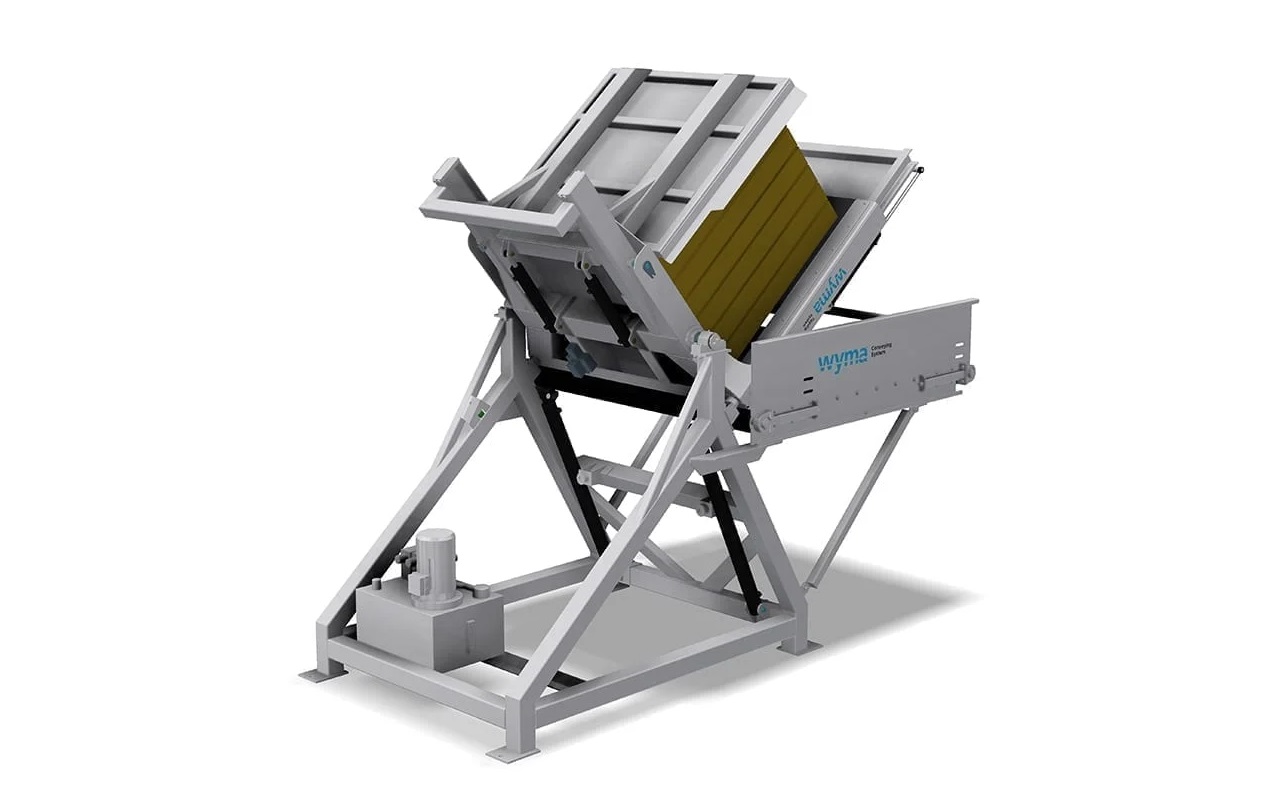

Evenflow

Wyma´s Evenflow Hopper evenly supplies produce on-demand to the next stage in your line, converting an irregular infeed to a constant outfeed flow.

Wyma’s Evenflow Hopper is a combination conveyor and hopper. It evenly supplies produce to the next piece of equipment in your line (in a continuous process). It converts an irregular infeed supply to a constant outfeed flow. It can also provide buffer storage.

The Evenflow Hopper starts in a raised position with the infeed end of the conveyor bed as high as it can go. When a sensor detects produce on the conveyor, the end of the conveyor lowers, creating a produce storage area. As produce backlog clears, the end of the conveyor lifts back up.

This sensor-controlled system can be set up so produce is only fed to the next piece of equipment as it is needed (on-demand).

There are two motors; one driving the conveyor and one driving the up-and-down movement.