Wyma Solutions

Conditioning

Revolutionizing Parsnip Processing: Frederick Hiam’s Journey to Automation

Frederick Hiam leads the way in vegetable processing innovation with Wyma’s Optical Roto-Cut, enhancing precision, reducing waste, and boosting efficiency

Frederick Hiam Limited has been a trusted name in fresh produce for nearly a century. As they approach their 100th anniversary, they continue to set new industry benchmarks in vegetable processing. Their latest venture—an ambitious modernization of their parsnip processing operations—demonstrates their commitment to efficiency, sustainability, and innovation.

Project Overview

Frederick Hiam partnered with Wyma Solutions to revolutionize their parsnip processing. This transformation was executed in two phases:

- Phase One: Installation of a new washing and intake line, which will significantly improve the initial handling of raw produce.

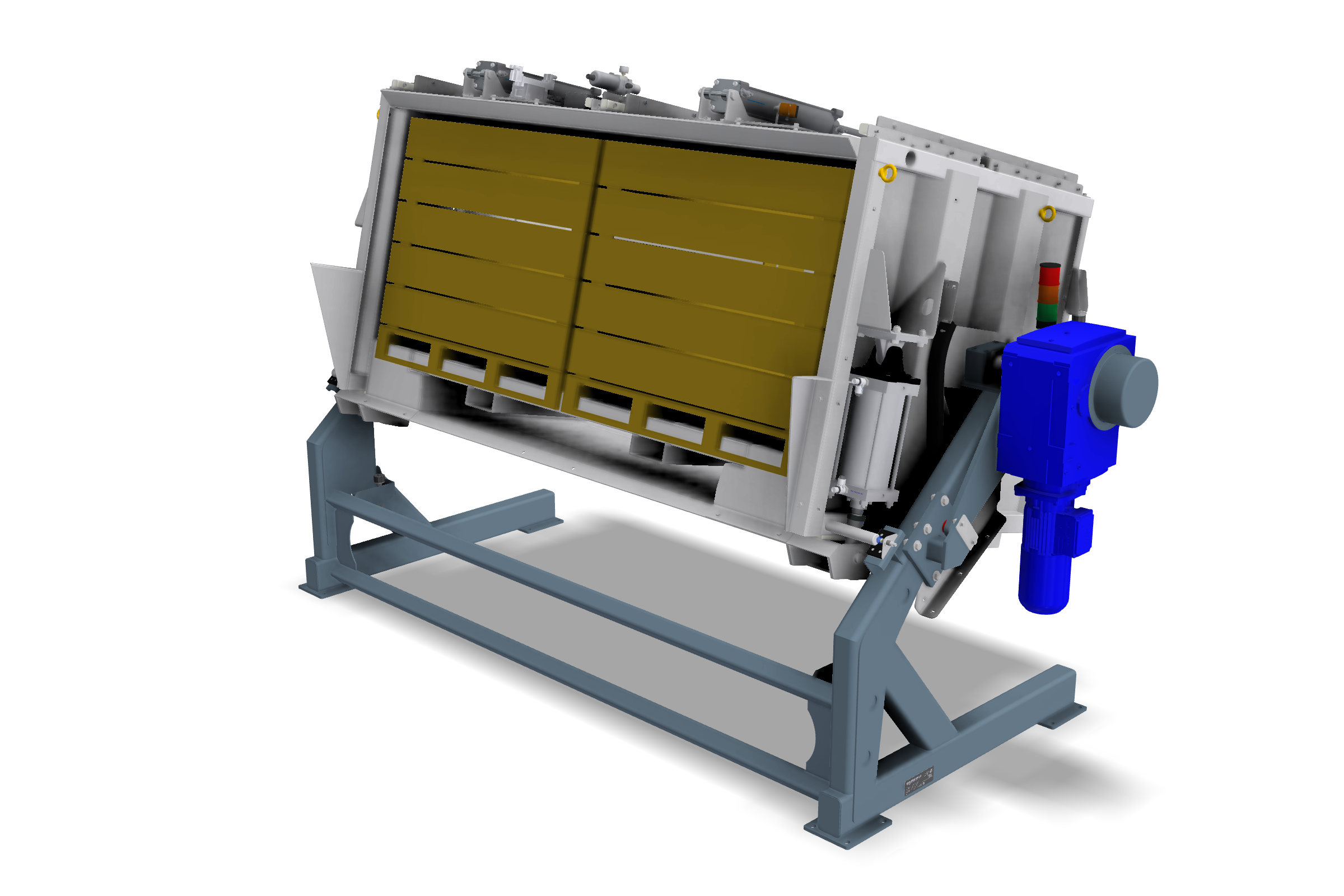

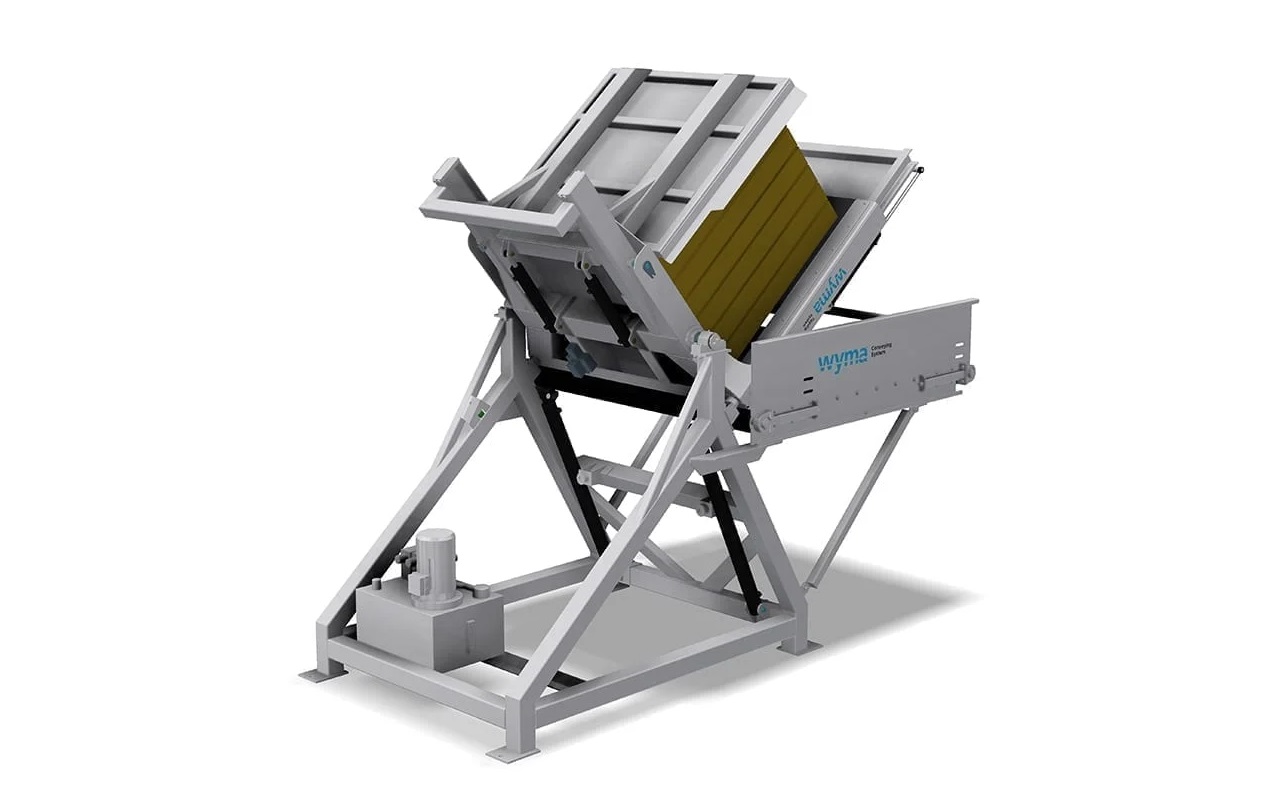

- Phase Two: Implementation of cutting-edge trimming technology, including Wyma’s innovative Optical Roto-Cut system.

This collaboration delivered measurable improvements in energy efficiency, labor reduction, and processing accuracy, ensuring Frederick Hiam remains at the forefront of modern food production.

Key Achievements

Energy and Water Efficiency

- 25% reduction in electricity usage, a crucial benefit amid rising energy costs.

- 25-30% savings in water consumption, ensuring compliance with increasingly stringent licensing regulations.

Labor Optimization

- Transitioned from 20 manual operators on the trimming line to just 2, significantly reducing labor dependency.

- Enabled a consistent throughput of 6 tonnes per hour, meeting the growing demand efficiently.

Precision and Productivity Gains

- Achieved 95% trimming accuracy, minimizing crop waste and ensuring product consistency.

- Doubled throughput, improving efficiencies across the supply chain and enhancing both supplier and customer satisfaction.

A Tailored Approach to a Niche Challenge

Parsnips, a specialized crop, require precise handling. Off-the-shelf solutions were insufficient, so Frederick Hiam and Wyma Solutions co-developed the Optical Roto-Cut system, integrating advanced computer vision for precise trimming. The system was fine-tuned on-site, adapting to varying crop conditions to ensure optimal performance.

Wyma’s expertise facilitated the seamless integration of this new technology into Frederick Hiam’s existing factory setup, overcoming logistical challenges from the first phase of the project. Their collaborative and flexible approach ensured that every aspect of the system met Frederick Hiam’s specific operational needs.

Industry-First Innovation

Frederick Hiam now proudly operates the world’s first fully automated parsnip trimming line, setting a new industry standard in efficiency and technological advancement within the fresh produce sector.

Jamie Lockhart, Managing Director at Frederick Hiam, said:

“There are certain moments in business when you just know you’re on the right track. This partnership with Wyma has been transformative for us.”

Positioning for Future Growth

The success of this project has paved the way for further strategic advancements:

A new partnership with Burgess Farms, positioning Frederick Hiam as the leading processor of retail parsnips.

The establishment of a grower group, optimizing supply chain operations, and strengthening their position for long-term growth.

By embracing automation and sustainability, Frederick Hiam Limited continues to lead the way in fresh produce innovation, ensuring it remains a powerhouse in the industry for generations to come.