Wyma Solutions

Conditioning

The OptiClean Initiative's Fight Against Food Waste

The OptiClean project enhances the washing and polishing of root vegetables to reduce food waste by extending their shelf life, supported by Denmark's Green Development and Demonstration Programme

The OptiClean initiative, supported by a 5.5 million DKK grant from Denmark's Green Development and Demonstration Programme (GUDP), aims to tackle the problem of half-rotten carrots in consumers’ vegetable drawers. By optimizing the washing and polishing processes, the project seeks to reduce food waste across the industry, retail chains, and consumers. Wyma was fortunate enough to be invited to participate in this project, offering decades of vegetable washing and polishing experience.

Background

Food waste in the fruit and vegetable industry ranks among the highest in terms of wasted crop. Many of us are familiar with the scenario of checking the fridge or pantry only to find forgotten, half-rotten produce destined for the compost bin. Consumers' preference for flawless, fresh produce, combined with the short shelf life of fruits and vegetables, leads to nearly 100,000 tonnes of waste in Danish households each year. This necessitates a closer examination of handling methods to improve shelf life.

A crucial aspect of handling root vegetables, such as carrots, beetroot, and potatoes, is the washing process. When you walk into a grocery store today, the sight of root vegetables is far different from what you would see in the fields where they were harvested. Most root vegetables undergo washing before reaching consumers to appear clean and appealing on the shelf and to make them easier to handle in the kitchen. However, while this practice boosts consumption, it also shortens shelf life. The washing process removes soil but introduces microorganisms from the soil into the water. These microorganisms aren't harmful but can promote rotting and reduce shelf life, especially during the subsequent polishing step. Polishing removes the remaining soil but can also damage the vegetable peel. If the peel cells break and aren't repaired, it creates an environment for microorganisms to thrive.

The Project

To address these issues, the OptiClean project, led by Merete Edelenbos, aims to optimize the washing process to increase the shelf life of root vegetables by 7-10 days, thereby reducing food waste. The project will evaluate different brushing techniques and their effects on carrot durability. Additionally, it will explore non-chemical solutions, such as ozone, to improve the quality of the process water used in washing.

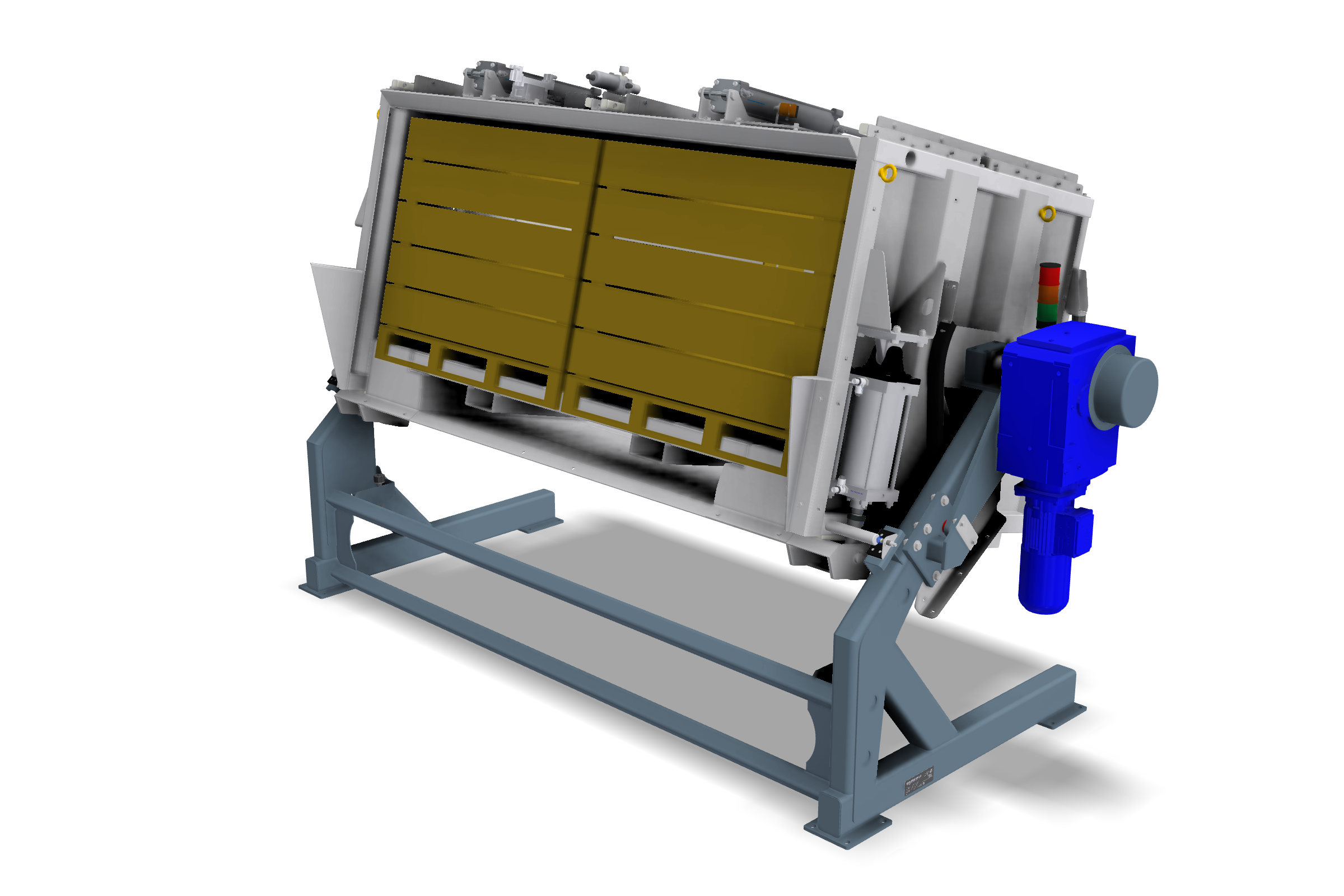

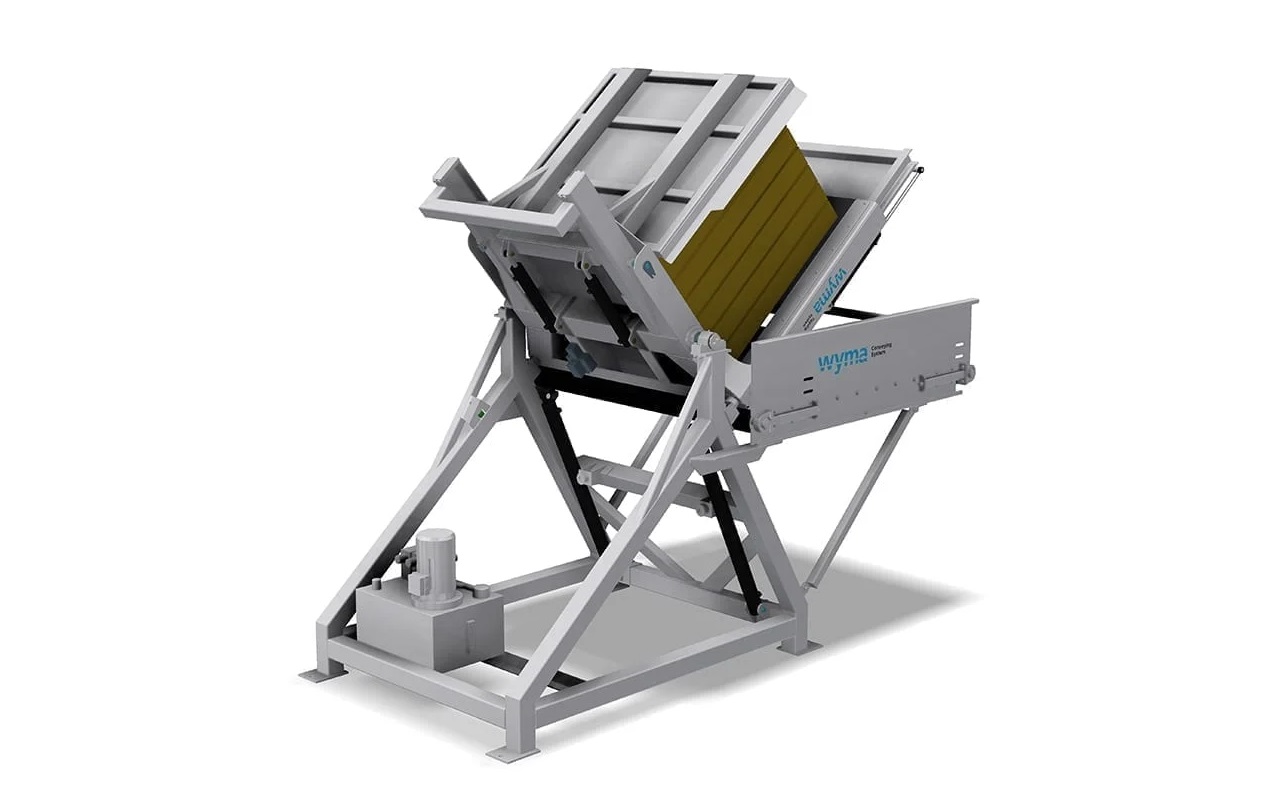

Respected globally as the vegetable cleaning experts, our team was asked to join the OptiClean project. Along with years of manufacturing and R&D experience, Wyma has provided the project with a test rig polisher, which processes carrots at various speeds and harshness to determine an optimal level of cleaning and polishing by examining skin damage.

We hope that being involved in this project will allow us to actively contribute to the sustainability and future of our industry. It helps us improve our own products, offering the market better solutions that improve yield, reduce produce waste, and ultimately lower the overall carbon footprint by reducing emissions and land requirements.

If successful, OptiClean's efforts will benefit processors, suppliers, retailers, and consumers, who will notice fresher produce lasting longer in their refrigerators or pantries. The project, funded by a 5,465,865 DKK grant from GUDP, is scheduled to run until the end of 2025.