Maf Roda

Conditioning

Turnkey solutions for cherry handling and packaging

MAF RODA has been leading the constant technological evolution linked to the processing of fresh fruits and vegetables since 1905. We develop tailor-made projects for you. With our excellence and technological quality, we are capable of providing you with a global solution that addresses every step of the process, from fruit reception to final palletizing and strapping.

The tomato family presents a significant diversity of varieties, both in size, shape, and color. MAF RODA AGROBOTIC has designed machines that will allow you to carry out the classification and packaging of all types of tomatoes, from the smallest cherry tomatoes to the largest beef tomatoes, including tomatoes in bunches.

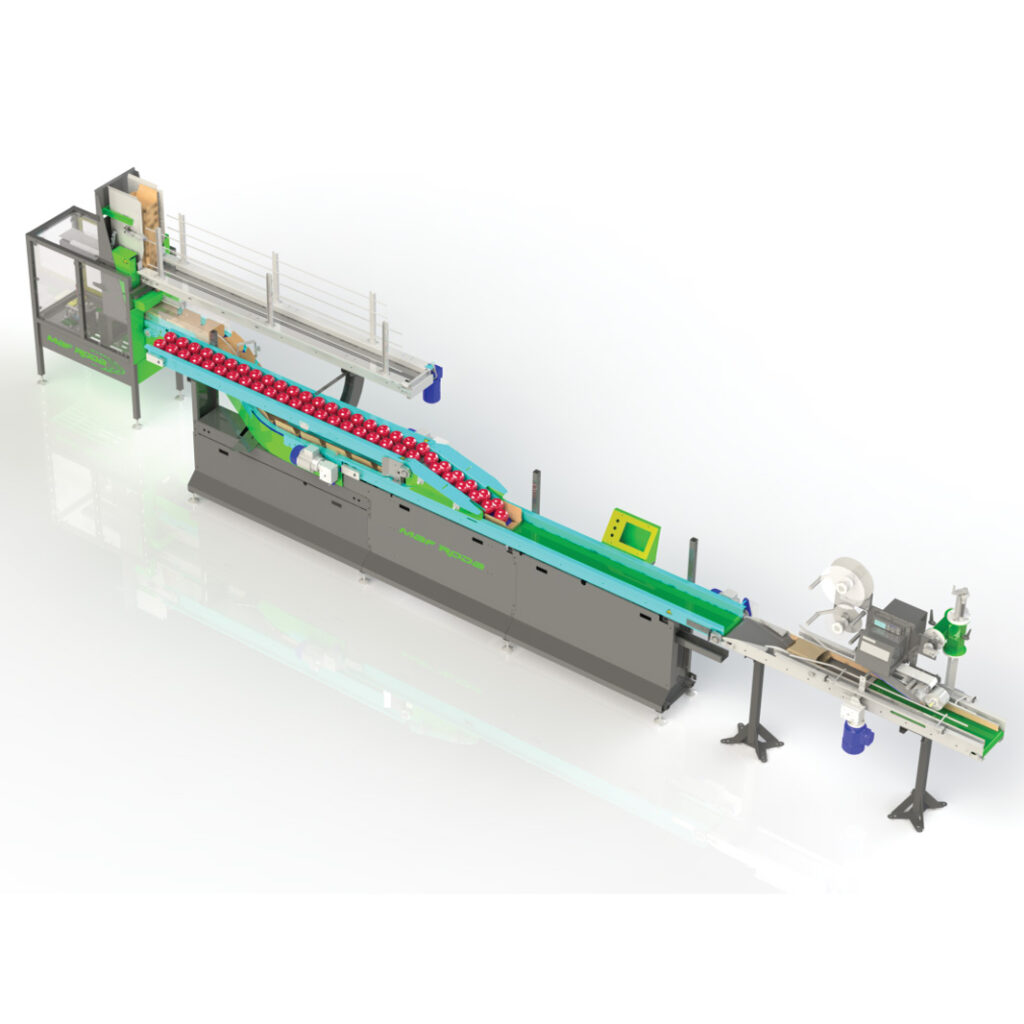

Automatic feeding systems

MAF RODA's automatic feeding systems aim to optimize production and line performance with continuous and homogeneous dumping, achieving a high filling rate.

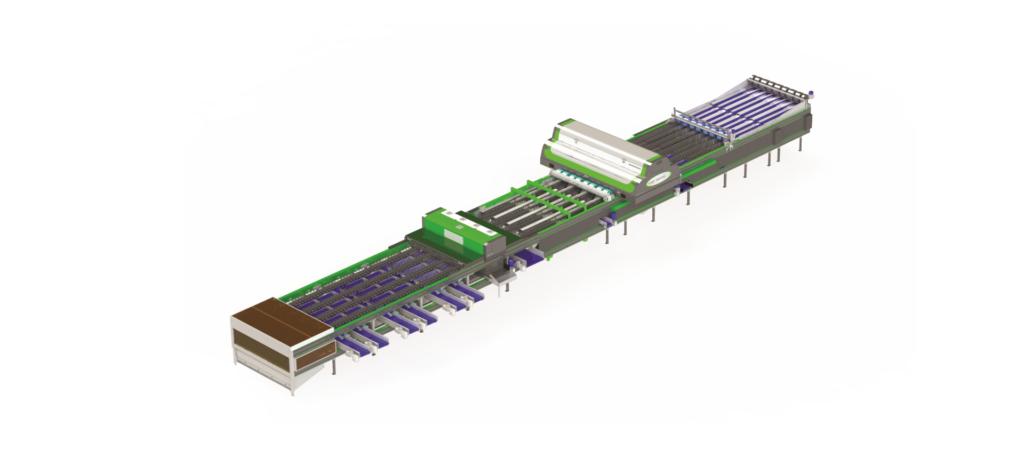

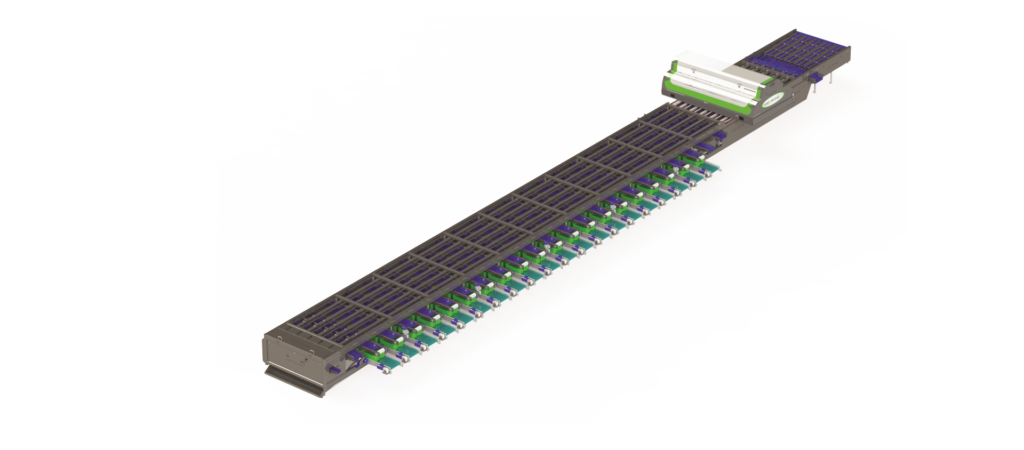

Calibration and sorting systems for tomatoes

Our calibrator, POMONE, is renowned for its versatility and for handling fruit with extreme gentleness. The ergonomic design of the transport hands allows for precise weight and fruit distribution towards the exits gently and delicately.

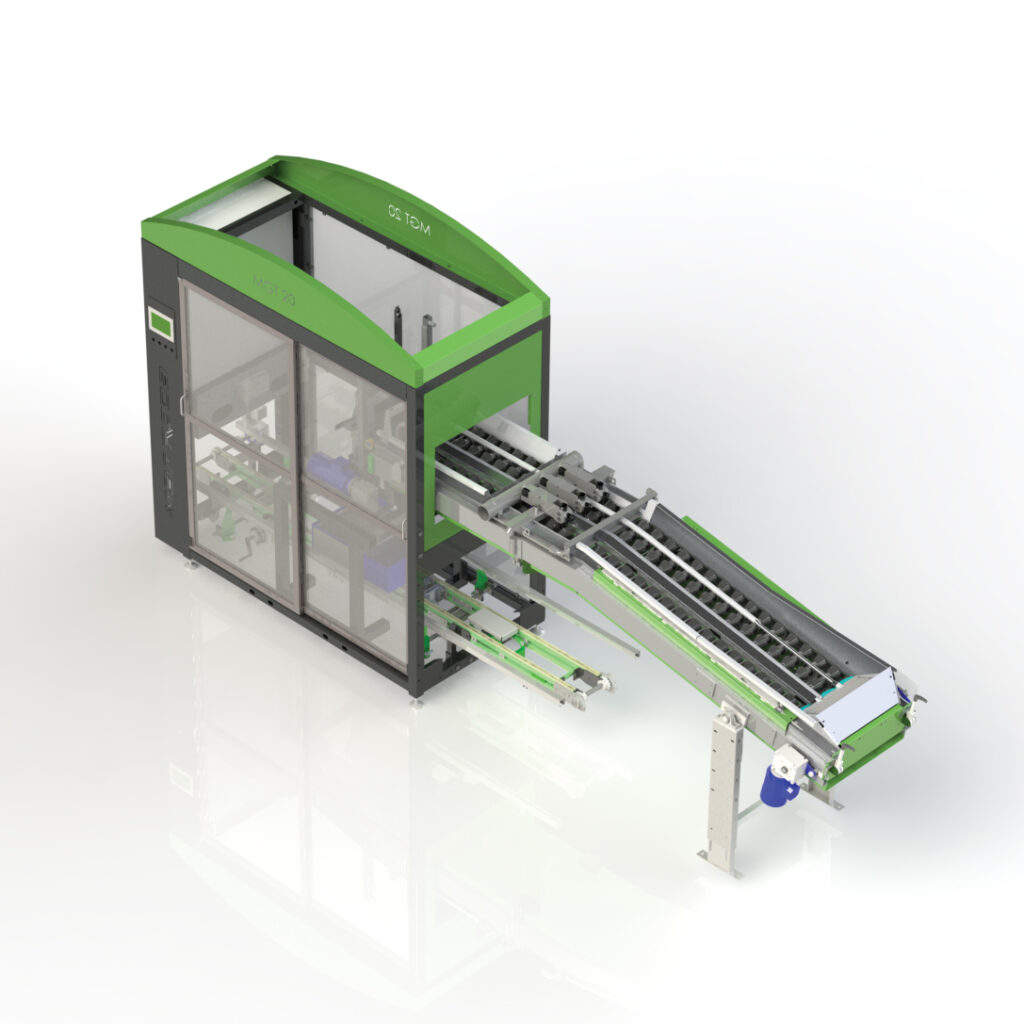

Calibration and sorting systems for cherry tomatoes

CHERRYWAY IV represents a significant advancement in optimizing and efficiency in cherry tomato processing thanks to its adaptability to elongated cherry varieties and the patented rotation system.

Sorting and quality systems

GLOBALSCAN 7 is an electronic system for external fruit quality analysis. High-resolution images obtained with multispectral cameras, along with the new patented rotation system*, ensure a complete vision for precise analysis.

*Patented rotation system exclusive for cherry tomatoes.

Automatic packaging and palletizing systems

Our catalog offers a wide variety of automated filling and bulk packaging systems with built-in scales. These solutions are adapted to the new plastic-free regulations and range from bulk containers to individual baskets.