Packaging

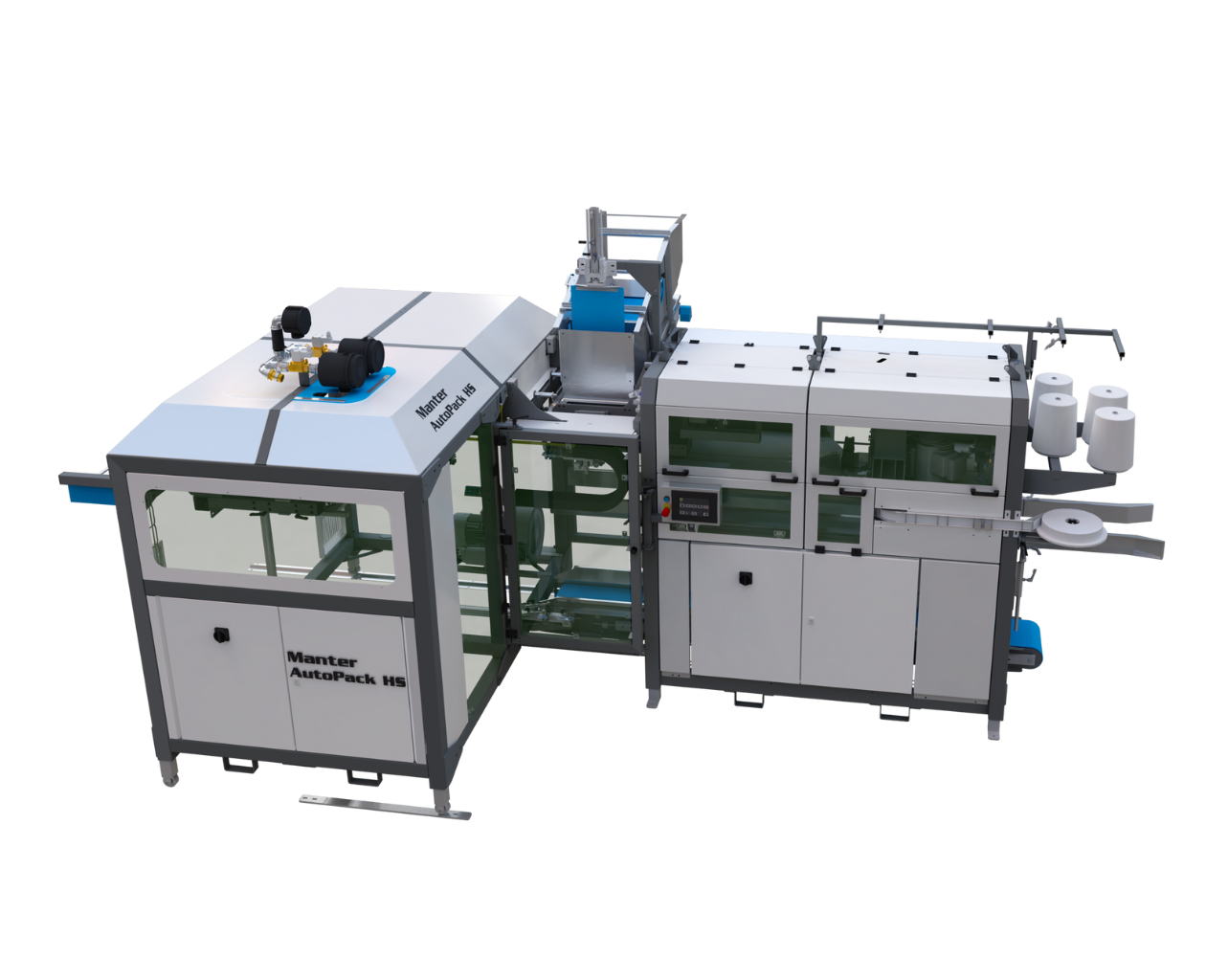

Manter upgrades AutoPack HS

Redaccion

Manter continues to enhance the already successful AutoPack HS (High Speed) in its ongoing effort to provide added value for its customers. The widely sold AutoPack HS has undergone significant improvements in the system responsible for separating and filling bags. These innovations result in a substantial increase in reliability and lead to higher output. The upgrade can be divided into three key improvements.

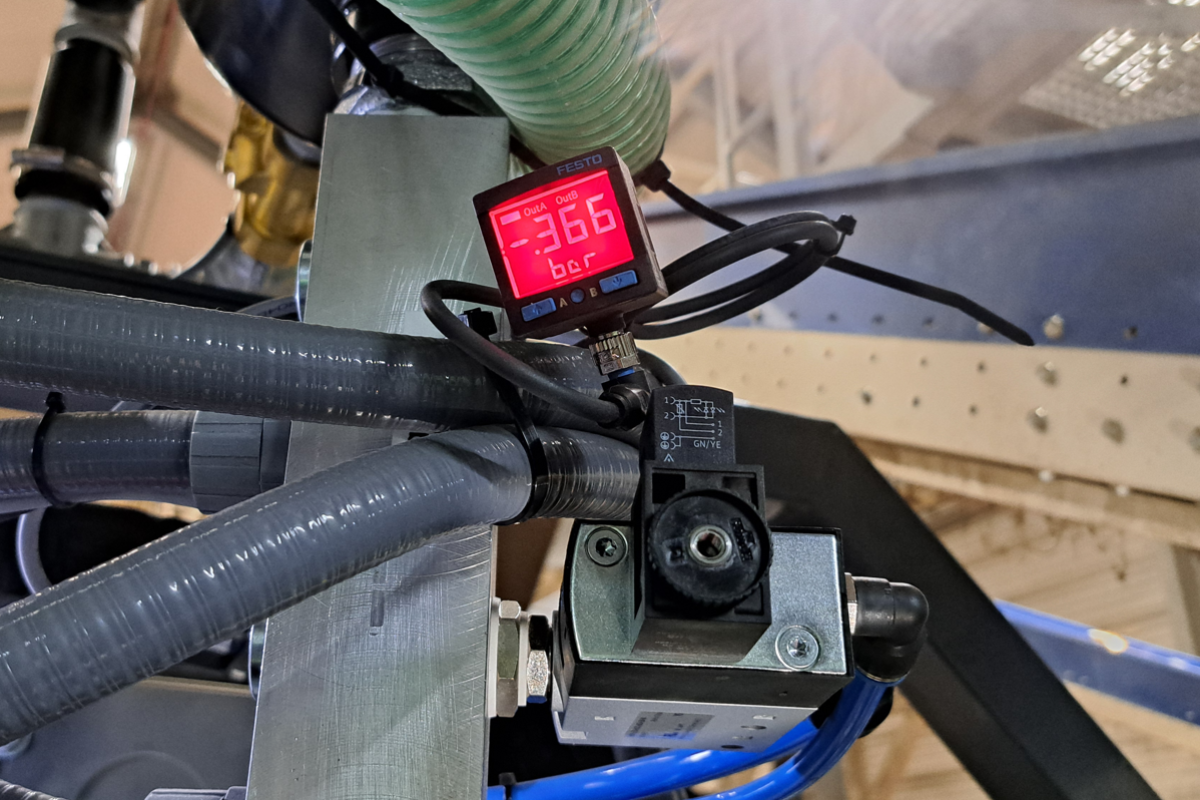

1. Vacuum System: Greater Suction Power, Less Loss

A major upgrade to the AutoPack HS is the new vacuum pump with three times the suction power. This ensures that the machine holds the bag more securely, even if the bag quality is lower. Additionally, the reliability of correctly positioning and sealing the bags under the filling head is significantly improved, resulting in higher output per hour.

Gert-Jan van der Laan, R&D Engineer at Manter, explains:

"By switching to a more powerful vacuum system, we have not only improved performance but also reduced maintenance needs. This directly contributes to higher uptime and lower operational costs for our customers."

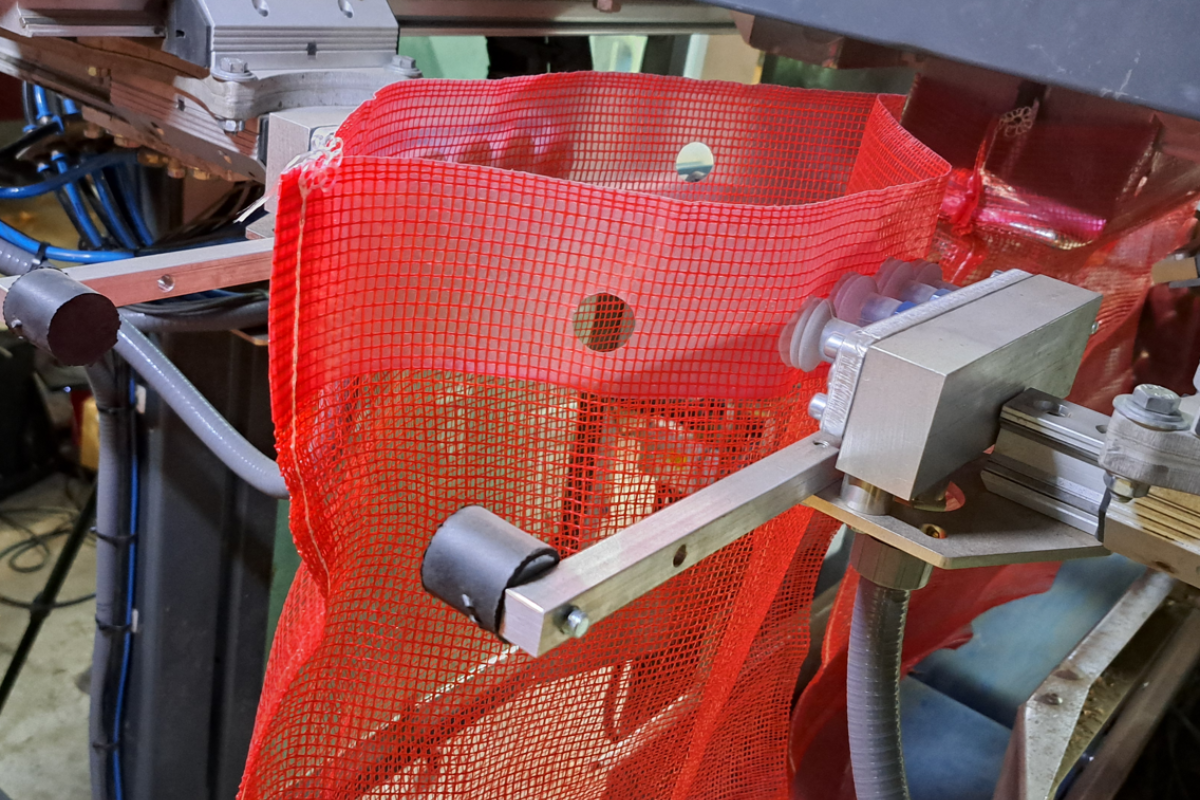

2. Improvements to the Singulator: More Bags in the Magazine

The design of the bag separator has been made more compact, creating additional space for more bags in the magazine. Additionally, larger suction cups have been installed to ensure a better grip and increased reliability.

Van der Laan adds:

"The adjustments to the singulator not only improve grip but also allow for more efficient operation. This means our customers can package faster and more reliably without added complexity."

3. Optimization of the Openers

The openers have also been equipped with larger hose diameters and fewer connections, resulting in reduced losses and smoother operation.

According to Van der Laan:

"Simplicity was key in developing these improvements. Fewer moving parts and an optimized airflow system mean fewer malfunctions and a longer machine lifespan."

.png)