Marvil Engineering

Cooling and CA

Breakthroughs in Controlled Atmosphere: Revolutionizing Fresh Produce Preservation

Marvil is renowned as a reliable, innovative, and expert partner in the fresh produce preservation industry

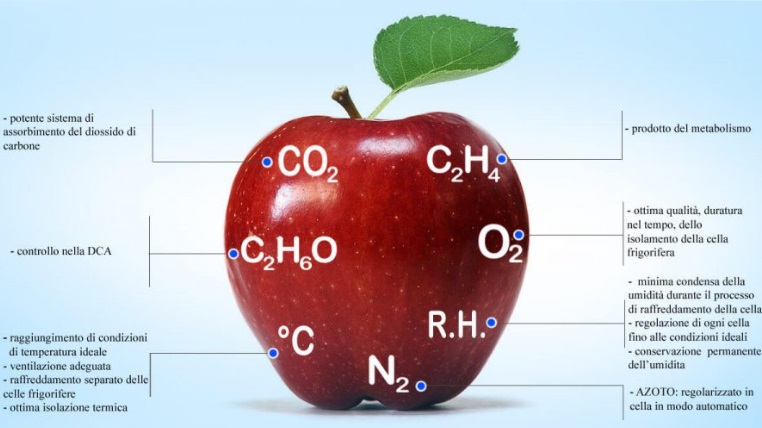

Fruits and vegetables continue to live and undergo metabolic processes even after they are harvested, consuming oxygen from the environment and producing carbon dioxide, water vapor, and various volatile compounds. Among these gases, ethylene plays a crucial role as a plant hormone that regulates the ripening process. As produce respites, its chemical composition changes, which can affect its flavor, texture, and nutritional value. This ongoing biological activity explains why fresh produce continues to evolve after harvest, impacting its shelf life and quality. Understanding these processes is vital for improving storage methods and preserving the freshness and quality of produce during transportation and at home.

Controlled Atmosphere: The Key to Prolonged Freshness

The management of these gases during cold-room storage is known as Controlled Atmosphere (CA). By carefully regulating temperature and relative humidity, CA provides optimal, natural preservation of fresh produce without the need for chemical additives. This process slows the metabolism of the produce, helping it retain its freshness and vitality, so it arrives on our tables looking and tasting as fresh as when it was harvested.

Slowing down the metabolism during the conservation process is crucial, beginning right from harvest. Therefore, it is essential that fruits reach the storage facility promptly and undergo the correct treatment to ensure proper preservation, maintaining their quality and freshness throughout the storage period.

Marvil's rooms, equipment, and technologies are designed to keep fruits as fresh as if they were just harvested, even after months of storage. With years of experience, Marvil's specialized technicians are well-equipped to recommend the most effective and precise methods for preserving your products, delivering results that exceed expectations.

Cutting-Edge Automation

Typically, Marvil's cold storage rooms are gas-tight, creating sealed environments where the levels of O2, CO2, nitrogen, and ethylene can be precisely controlled.

Thanks to the plant's full automation, the simplicity of its control system, parameter recording, and intuitive display, combined with user-friendly man-machine interfaces, remote control capabilities via a smartphone app, and an open data transmission system accessible to third-party control programs, Marvil's systems are regarded as some of the simplest and most reliable on the market.

Innovations in Dynamic Controlled Atmosphere (DCA) - ILOS PLUS-DCA

In recent years, a variety of advanced techniques have been developed to achieve increasingly lower oxygen and carbon dioxide levels during produce storage. Following the ULO (Ultra Low Oxygen) system, which was the dominant method in the previous century, the DCA (Dynamic Controlled Atmosphere) method emerged in the 2000s as an evolution of the ILOS (Initial Low Oxygen Stress) system. This innovative approach was designed to address a storage-related disorder known as superficial scald—a condition commonly observed in certain apple and pear varieties that occurs after prolonged storage—without the use of chemicals.

The DCA method works by reducing the oxygen content to near-anoxic levels. While this can be potentially harmful and, if uncontrolled, may lead to the death of the fruit, when carefully managed, it triggers a stress response in the fruit. This metabolic slowdown acts as a protective mechanism, significantly extending the fruit's shelf life while maintaining its freshness, all without relying on chemical treatments.

Marvil's Reliable DCA Systems

With Marvil's technology, the risks associated with this technique are mitigated, delivering excellent results. The superficial scald issue is fully eliminated, and the shelf life of the fruit is extended after it leaves the storage facility. This process involves a significant slowing of the fruit's metabolism during storage, followed by a carefully controlled reintroduction of normal atmospheric conditions and temperatures. This gradual restoration allows the fruit's natural metabolic processes to resume, enabling controlled ripening, resulting in fruit that is full of flavor and ready to be enjoyed.

Marvil’s systems integrate nitrogen generators, CO2 absorbers, and ethylene converters within fully or partially automated systems. These systems are complemented by advanced computerized analysis, ensuring high-quality results and efficient processing. This natural technique, based solely on regulating the composition of the room air, requires no chemical additives, offering an eco-friendly and effective solution for preserving the freshness and quality of produce.

To monitor and control the dynamics of the process, Marvil employs two advanced devices. First, a sampling and analysis system measures the ethanol produced in the fruit's pulp, offering valuable insights into the metabolic activity of the fruit. Second, the SDS system, equipped with a specialized electronic device, measures the gases released during metabolism. This system also includes an index to assess the stress levels of the fruit, enabling precise monitoring and management of the conservation process.

Flexible Solutions for Smaller Quantities

For smaller quantities or products typically found in small-sized batches, such as cherries or mushrooms, a practical solution is the CA or ULO system in pallets.

These products are placed on special boards and bagged in thick polyethylene sacks. The pallets are then connected in a closed-loop system. An automatic control system regulates the gases inside the pallets, ensuring optimal preservation through a simple and efficient method.

This approach eliminates the need to fill an entire room with product. Instead, it allows for flexible, daily storage in the controlled atmosphere. Additionally, individual pallets can be easily detached from the circuit at any time without disrupting the preservation of other pallets, offering both convenience and efficiency.

Quick Cooling for Overseas Shipping

In the conservation chain, it is crucial to begin cooling immediately after harvest and processing, particularly when prepearing for overseas shipping.

Marvil has perfected a movable, low-impact quick cooling system designed for installation in existing cold storage units. This system significantly reduces cooling time, even within completely sealed or poorly ventilated packages, ensuring optimal preservation of the produce throughout its journey.