Marvil Engineering

Cooling and CA

Revolutionary Advances in Berry Preservation and Banana Ripening at Fruit Logistica 2025

Marvil Engineering Unveils Cutting-Edge Innovations at Fruit Logistica 2025: Advanced Berry Preservation with CA and the Next-Generation Ripening Cycle Scheduler

Marvil Engineering, a global leader in Controlled Atmosphere (CA) technologies, made a significant impact at Fruit Logistica 2025, presenting two of its most innovative solutions: berry preservation in individual pallets with CA and the new Ripening Cycle Scheduler. These advancements reinforce Marvil Engineering’s commitment to enhancing fruit storage, extending shelf life, and optimizing ripening processes through state-of-the-art technology.

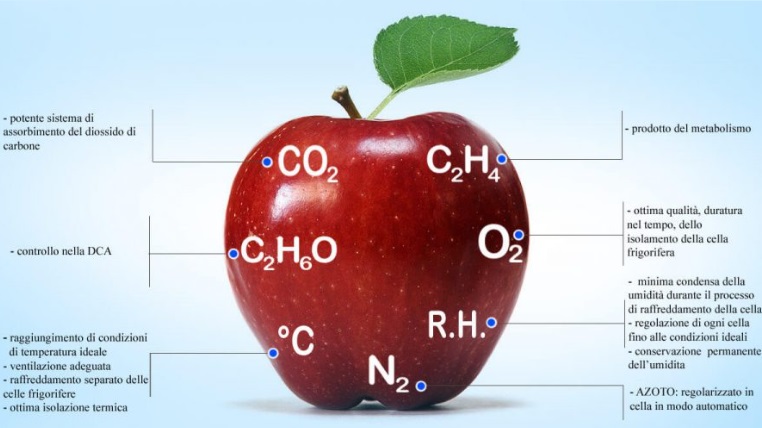

Pioneering Excellence in Controlled Atmosphere Technologies

Founded in 2003 in South Tyrol (Bolzano, Italy), Marvil Engineering has built a strong reputation for innovation, reliability, and expertise in the field of fruit storage. With over 550 installations worldwide, including in Europe, South America, Asia, and the world’s leading fruit-producing regions, Marvil continues to set new standards in the industry. More than 400 of these installations utilize Dynamic Controlled Atmosphere (DCA) technology, ensuring superior preservation, extended freshness, and exceptional fruit quality.

Marvil Engineering provides cutting-edge solutions tailored to the modern fresh produce industry, including:

-

Fresh produce conservation – AC, ULO, and Dynamic Controlled Atmosphere (ILOS PLUS-DCA) for optimal preservation.

-

Pallet ripening systems – Precision-engineered solutions for efficient, uniform ripening.

Berry Preservation in Individual Pallets with CA

Marvil Engineering showcased its advanced berry preservation technology, specifically designed for individual pallet storage using Controlled Atmosphere (CA).

Berries possess exceptional nutritional and organoleptic qualities but are also among the most delicate and perishable fruits. Their increasing global demand presents a challenge for producers who must ensure consistent freshness and quality.

Marvil’s specialized CA storage system provides an effective and economical solution for prolonging the shelf life of berries while preserving their flavor, texture, and market value.

Key Advantages:

- Maximum flexibility in product management and sales

- Ideal for small product quantities

- Practical and cost-effective

- Adaptable to any cold storage facility

- Superior preservation and extended shelf life

By enabling sequenced product sales, Marvil ensures that berries consistently reach the market in peak condition, reducing waste and maximizing profitability for producers and distributors.

Revolutionizing Banana Ripening with the Ripening Cycle Scheduler

Another highlight of Marvil Engineering’s showcase was its Ripening Cycle Scheduler, a highly sophisticated system for optimizing banana and tropical fruit ripening. This innovative solution is designed for seamless integration across various ripening setups, from mini chambers to large-scale ripening rooms.

Advanced Features and Benefits:

-

Precision ripening control: Ensures optimal degreening, astringency removal, and batch-specific treatments.

-

Network connectivity: Secure remote access allows for real-time monitoring and centralized control.

-

Optimized efficiency: Enables producers to adjust cycles based on environmental conditions, fruit quality, and origin.

-

Sustainability-focused: Minimizes waste and enhances product consistency, delivering higher economic returns.

By offering a fully connected and automated system, Marvil’s Ripening Cycle Scheduler provides producers with unprecedented control and efficiency, redefining industry standards for banana ripening.

Shaping the Future of Fruit Storage and Ripening

Marvil Engineering’s participation in Fruit Logistica 2025 underscores its role as a pioneer in CA and ripening solutions. With its ongoing commitment to research and development, Marvil continues to deliver technologies that enhance efficiency, sustainability, and profitability for the global fruit industry.