Measurements

Analytic Texturometer for deep analysis of food and soft materials

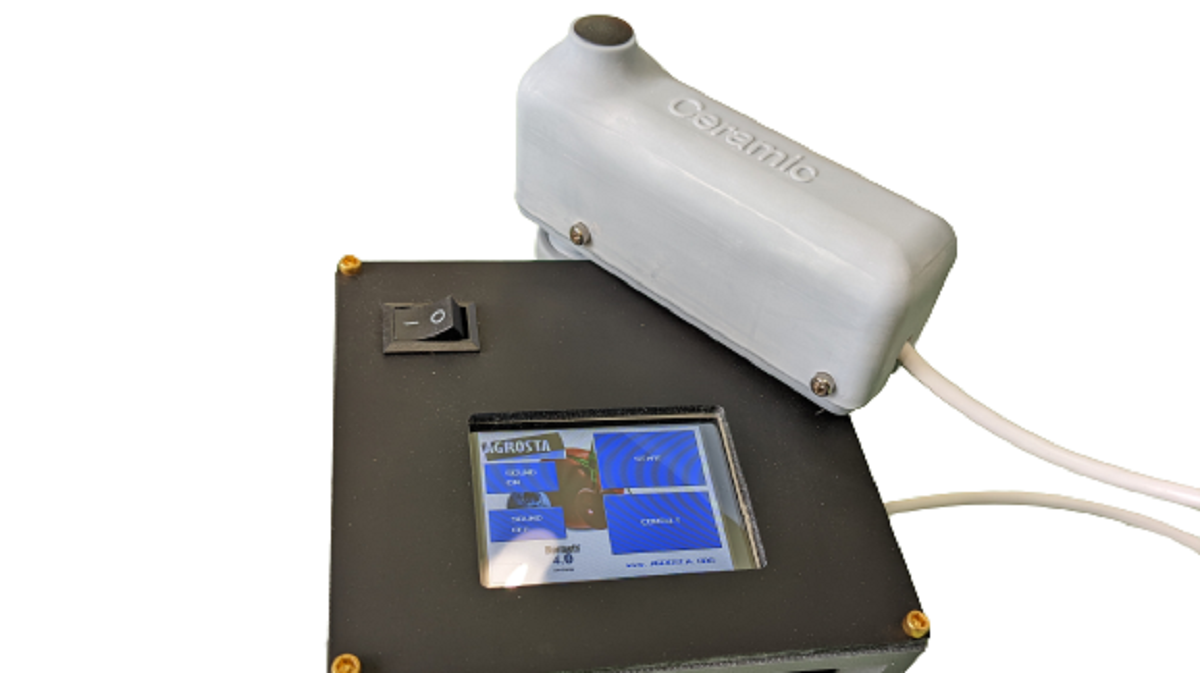

The Agrosta®Texturometer Version 2 has been designed in 2016 by AGROSTA, it is a simple and reliable tool to determine : freshness, spreadability, tenderness, springiness, gumminess, hardness, firmness, consistency, fracturability, creaminess, mouthfeel, consistency, tackiness, drip point, springback, adherence, pliability, coherence, viscosity, creep, breaking point, compressibility, rubberiness, bloom strehgth, crispiness, density, lumpiness, needle sharpness, slipperiness, smoothness, softness, surface rupture, structural memory, relaxation under load, polymer cure, etc. of a wide variety of Food Products, packagings and soft materials.

16 February, 2017

The Agrosta®Texturometer Version 2 has been designed in 2016 by AGROSTA, it is a simple and reliable tool to determine : freshness, spreadability, tenderness, springiness, gumminess, hardness, firmness, consistency, fracturability, creaminess, mouthfeel, consistency, tackiness, drip point, springback, adherence, pliability, coherence, viscosity, creep, breaking point, compressibility, rubberiness, bloom strehgth, crispiness, density, lumpiness, needle sharpness, slipperiness, smoothness, softness, surface rupture, structural memory, relaxation under load, polymer cure, etc. of a wide variety of Food Products, packagings and soft materials. We have designed this machine in order to provide a very simple and efficient tool for a reasonable cost. You can adjust and select the following parameters with the software :- a: + fast speed in microseconds (microseconds between 2 steps of motor, 320 steps for 1mm stroke, minimum 50µs) - b: + slow speed after first contact with the sample, in microseconds- c: + stroke after first contact with sample in 1/10 of mm- d: + threshold in grams (For how many grams does the machine consider that the tip is in contact with sample), we recommend a minimum of 50 grams- e: + first return speed in µs f + backlash compensation in 1/10 of mm (Mechanical clearance compensation) - g: + second slow speed in µs, if not indicated, the machine does not make a second cycle (Second cycle is used to determine springiness) - h: + second stroke in 1/10 of mm - k: + return stroke between first and second pressure, in 1/10 of mm - j1: To start the cyclel1Tare From research point of vue (deep analysis of few samples)The software, collects the pressure each 10 milliseconds, records them in a chart that can be exported to Excel, and displays a curve. This is the texture analysis philosophy. From production / quality control point of vueWith the same software, you can decide to collect only the maximum pressure of each sample, classify the data by batch, and calculate statistics for each batch. This is the batch control philosophy. A voltage booster has been embedded in this last version in order to keep accuracy even with low battery levels of laptops or tablets. Pressure capacity : from 50 grams to 20 Kg (Can be configured in Grams and Lb). Provided with:- A software for Windows XP, 7, 8, 10- 1 Beaker- One plate (You can choose to use a beaker or a plate)- 5 different tips according to your requests (We have more than 100 tips designs)- A power supply & a USB cable- A certificate of conformity- A manual Improvements in November 2016: Bloom test, and reinforced rigidityWith a specific button in the software, the machine is now able to perform the bloom test, which consists in calculating the force in grams needed by a 0.5 inch plunger to depress the surface of the gel by 4mm without breaking - Specific test for gel, jelly, gelatins, glues... When used to perform the bloom test on gelatin or gel, the machine is configured with a load cell having a capacity of 5 Kg instead of 20 Kg, and a specific software is provided. More information

https://youtu.be/NmhXsxsEJs4