Packaging , Processing , Services

Automated processes due to networked identification

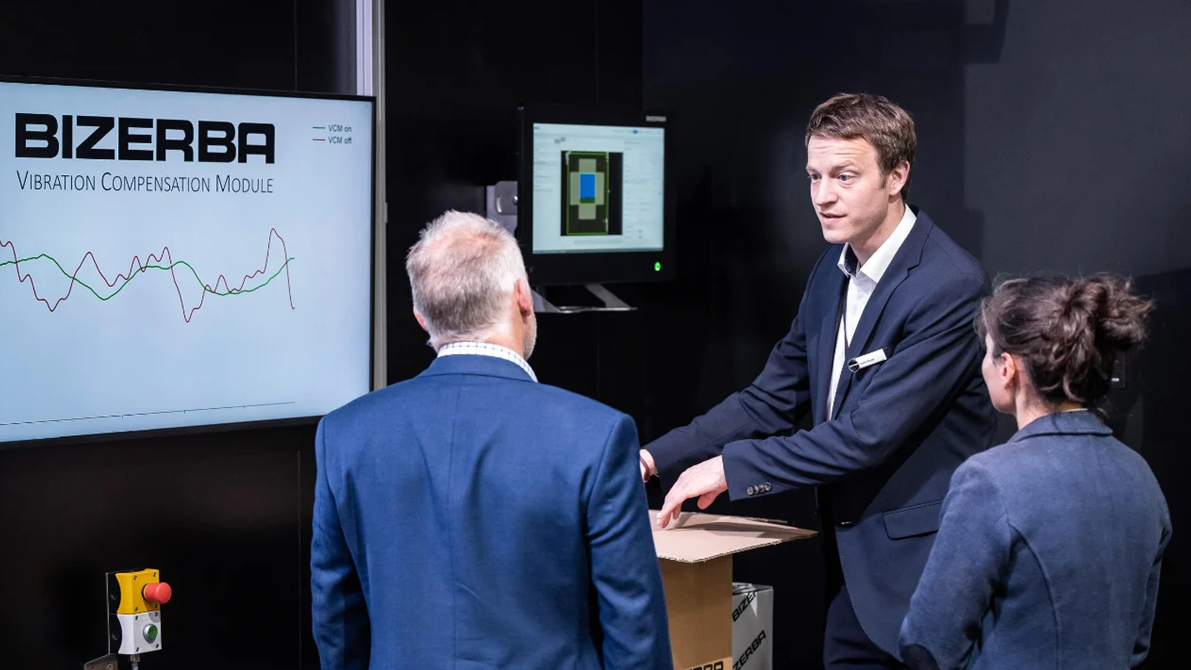

Start your automated processes now with future-proof BIZERBA vision inspection systems. The digital solutions ensure a networked, smooth workflow and flow of data along your production. Your processes automatically become more economic, transparent and completely traceable. 4 strong competitive advantages in the competitive food industry. Broad and flexible range of applications Automatic product recognition offers you a broad range of applications like during chaotic production The Bizerba vision inspection system is intelligent. It downstream product inspections automatically adapt to current products. Automatic control, which saves you time and avoids manual errors. And yet another highlight for you: You deploy qualified personnel for more value-adding processes.

08 April, 2021

Start your automated processes now with future-proof BIZERBA vision inspection systems. The digital solutions ensure a networked, smooth workflow and flow of data along your production. Your processes automatically become more economic, transparent and completely traceable. 4 strong competitive advantages in the competitive food industry. Broad and flexible range of applicationsAutomatic product recognition offers you a broad range of applications like during chaotic production The Bizerba vision inspection system is intelligent. It downstream product inspections automatically adapt to current products. Automatic control, which saves you time and avoids manual errors. And yet another highlight for you: You deploy qualified personnel for more value-adding processes. Your data-based Bizerba solution offers you more performance. It recognizes products in real time, inspects, verifies, classifies and sorts them qualitatively and/or quantitatively. You digitally define parameters and quality criteria matching your products: - Automatically check, for instance, if your convenience product includes all components.- Make sure that only correctly packaged products (in terms of quantity or mixture) enter the packaging station.- Check the appearance of your products such as visual appearance or size. This broad spectrum also supports your quality management in warehouse logistics, from goods receiving and intermediate storage to final storage. Protecting the environment and saving resourcesAutomatic product recognition has a positive effect on your balance sheet ecologically and financially. In other words, you save valuable resources such as food, packaging material, energy, time and costs with your Bizerba vision inspection solution. Here are only 3 of numerous examples: - Reduce food waste. Process products visually not meeting your criteria in other products.- Save labels by labeling only flawless packages.- Reduce your packaging waste. Not conforming products are rejected before being packaged. About BizerbaBizerba offers its customers in industry, trade, and logistics a globally unique solutions portfolio of hardware and software around the central value "weight". This portfolio includes products and solutions related to slicing, processing, weighing, cashing, checking, commissioning and labeling. A wide range of services from consulting and service, labels and consumables to leasing complete the portfolio. Since 1866 Bizerba has made a significant contribution to the developments in the area of weighing technology and today is represented in 120 countries. The customer base includes globally operating companies in trade and industry as well as retailers, bakeries and butcheries. With around 4.300 employees worldwide and with its headquarters in Balingen, Baden Wuerttemberg, Bizerba has been in the same family for five generations. Additional production facilities are located in Germany, Austria, Switzerland, Italy, France, Spain, China and USA. Bizerba also has a global network of sales and service locations.