Packaging

Easy Open: what the mesh packaging was missing to be ideal

The Easy Open system has established itself this year as one of GIRÓ's main innovations, and thanks to this easy-open system, the mesh packaging has taken the last qualitative leap forward it needed to be the definitive solution. Already offering great visibility, breathability and an easy transport grip, the last attribute that the mesh pack needed was an easy-opening system that would allow the consumer to access the contents using only their hands. Giró has therefore developed this new patented system which promises to revolutionise the fruit and vegetable sector.

20 April, 2021

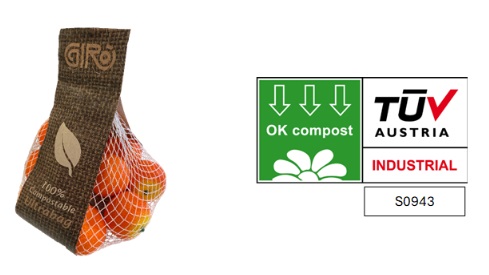

The Easy Open system has established itself this year as one of GIRÓ's main innovations, and thanks to this easy-open system, the mesh packaging has taken the last qualitative leap forward it needed to be the definitive solution. Already offering great visibility, breathability and an easy transport grip, the last attribute that the mesh pack needed was an easy-opening system that would allow the consumer to access the contents using only their hands. Giró has therefore developed this new patented system which promises to revolutionise the fruit and vegetable sector. Maximum utility, minimum complexityThrough in-depth research, Giró has found the perfect process to develop a practical and reliable easy-opening system for Ultrabag packaging. In other words, our UB-50, UB-60 and UB-65 packaging machines, both in first generation versions and in the new Speed Line generation, will be able to make this packaging. How do they do it?First of all, the packaging machine makes a small vertical cut in the mesh prior to the longitudinal sealing of the film. This film in turn incorporates a pre-cut window that is easy to tear, through which the consumer can easily access the contents of the pack. Thus, the consumer will open the film through the pre-cut area, which will reveal a window coinciding with the cut in the mesh, through which the contents of the pack can be extracted. By using the above system, Giró has developed two different types of easy-open systems: Open&CloseFirstly, we have the first Easy Open system developed by Giró called Open&Close. As its name suggests, this system allows the container to be opened and closed multiple times thanks to an adhesive label in the form of a tab applied to the pre-cut window. This window is designed so that, once part of the contents have been removed, it can be closed again, keeping the contents inside the pouch without them unintentionally coming out. In addition, this packaging can be used for a second use, e.g. compacting single-use plastic bags to be taken to the recycling bin. This saves a lot of waste space in the household. Another advantage is that, once used, it can be rolled up on itself and the label attached to compact it before recycling. Push&TearOn the other hand, there is the Push&Tear system, which makes the same vertical cut in the net, but superimposes a film with a different pre-cut design. The Push&Tear pre-die consists of a circle and a vertical line so that the consumer can access the contents by simply pressing the circle with their finger and tearing the vertical die downwards. This tabless die (and therefore, once opened, no longer closable), supports the pack structure without the need for added labels, so that we obtain a fully functional pack, with a system that is easy to open and just as sustainable as a normal net pack.

.jpg)