Packaging

Ecogiró Program: Sustainability at the center of the packaging strategy

Considering the changes that the packaging sector is undergoing, GIRÓ GROUP has placed at the center of its strategy the power to offer a range of products that adapt to the needs of most clients and legislations. For this reason, the range of products has been extended in such a way that alternatives can be offered to our customers based on 2 main pillars: optimization of the use of plastic and use of alternative materials.

29 November, 2022

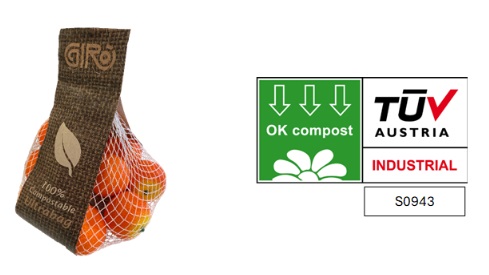

Considering the changes that the packaging sector is undergoing, GIRÓ GROUP has placed at the center of its strategy the power to offer a range of products that adapt to the needs of most clients and legislations. For this reason, the range of products has been extended in such a way that alternatives can be offered to our customers based on 2 main pillars: optimization of the use of plastic and use of alternative materials. 1. Optimization of the use of plasticFocused on those customers where the main material of the packaging they use is plastic and they believe that the solution is to lighten the packaging, reduce plastic waste to more reasonable levels, avoid mixing different plastics and facilitate recycling to enter the model named Circular Model. For these customers, the optimization of materials has not only allowed them to offer optimized packaging with less plastic but also to reduce costs. The main methods of materials optimization are: 2. Use of alternative materialsDuring the last few years, there has been an increased interest by society and governments in packages made from alternative materials. At Giró we see the virtues of plastic, but we also understand the negative effects of living in a world where single-use materials are so present. For this reason, Giró also has two ranges of solutions based on alternative materials without plastic: 100% organic solutions and our main innovation of 2021, 100% Cellulosic solutions. 2.1. 100% organic solutionsThis range is made up of the thermal-welded packages Girsac and Ultrabag with compostable film and net. The compostability of these materials allows them to be transformed back into organic matter (compost), thus promoting a circular model. The materials to produce compostable packaging have the TUV Austria certification 2.2. 100% cellulose solutionsGiró has launched in the market a third generation within the Ecogiró range, introducing the new 100% cellulose packages. This generation is based on materials of cellulose origin that allow thermal-welded packages (Girsac and Ultrabag) to be made, or clipped packages (WG and C2C). Clipped cellulose package:This package is comprised of a cellulose net, with a HOME COMPOST certificate, and a paper label that its clipped to the net. Once at home, the label can be easily separated from the net and placed in the paper bin for further recycling, while the cellulose net can be put in the organic bin. Thermal-Welded cellulose Package:In this case, the package is comprised of a cellulose net and a printed film of paper. The bag is sealed using a novel thermal-welded system. Once the package is made, it is not easy to separate the paper from the net, but as the weight of the paper is considerably higher than the weight of the net, the recommendation is to discard the entire package in the paper or cardboard bin.

.jpg)