Packaging , Processing , Services

Hygienic scales and weight control for untrained staff at the stand at Bizerba stand in Fruit Logistica

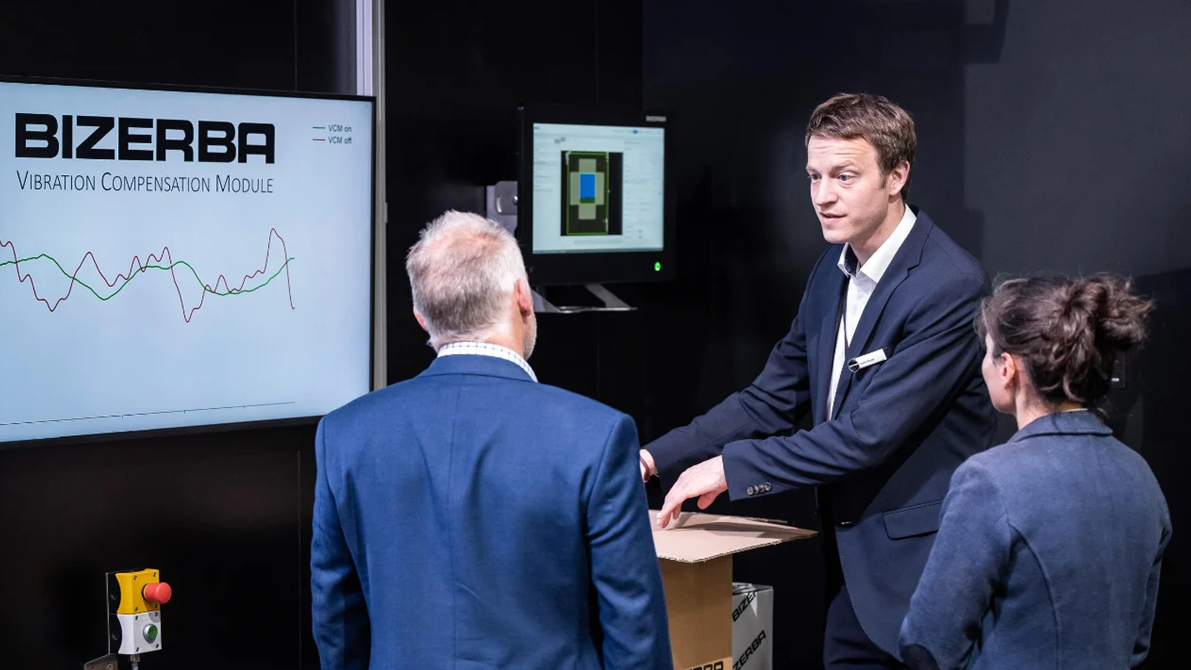

Bizerba showed on its stand at Fruit Logistica 2013 equipments like the CWE checkweigher, the automatic price labeler GLM-E 20/30, the box labeller GLM-B, the ray inspection systems XRE, the Statistics.Brain software, that records the entire process between the entry and exit of goods, and the LCE line converger, that optimizes package handling in material flow systems. They were joined by the production control system for trays

30 November, -0001

Bizerba showed on its stand at Fruit Logistica 2013 equipments like the CWE checkweigher, the automatic price labeler GLM-E 20/30, the box labeller GLM-B, the ray inspection systems XRE, the Statistics.Brain software, that records the entire process between the entry and exit of goods, and the LCE line converger, that optimizes package handling in material flow systems. They were joined by the production control system for trays developed in Spain for use in packaging plants with untrained staff, a bestseller among companies packaging strawberry and other berries and many other products such as grapes, mushrooms, chives, etc. An intuitive system based on light indicates whether the container is over or underweight; the Ethernet interface allows managing multiple working places, tracks the control statistics and allows an easy access to them at any moment (first image). Hygienic scales (2nd picture) are designed to work with fresh and allow perfect sanitation in all areas, so as to guarantee the absence of microorganisms causing quality losses and prevent potential health problems.