Measurements

Optimizing long-term potato storage with ethylene measurement

A group of scientists who were developing the optimum method of ventilation had to monitor gas exchanges in an effort to provide a commercially attractive balance of power consumption and potato quality preservation. Using the Felix F-900, they were able to make confident, data-driven reccomendations. Ventilation Can Control Ethylene Gas and Respiration in Controlled Atmospheres Potato (Solanum tuberosum L.) is the fourth most important food crop and a staple in many regions of the world. To make potatoes available year round, the tuber is stored in controlled atmosphere conditions. Temperatures higher than 2oC can lead to increased respiration and transpiration, which causes potatoes to lose around 5?8% weight in an 8-10 month storage period. Temperature also triggers ethylene production, which can alter the chemical composition of potatoes and, in later storage periods, enhance the sprouting of the tubers.

19 May, 2021

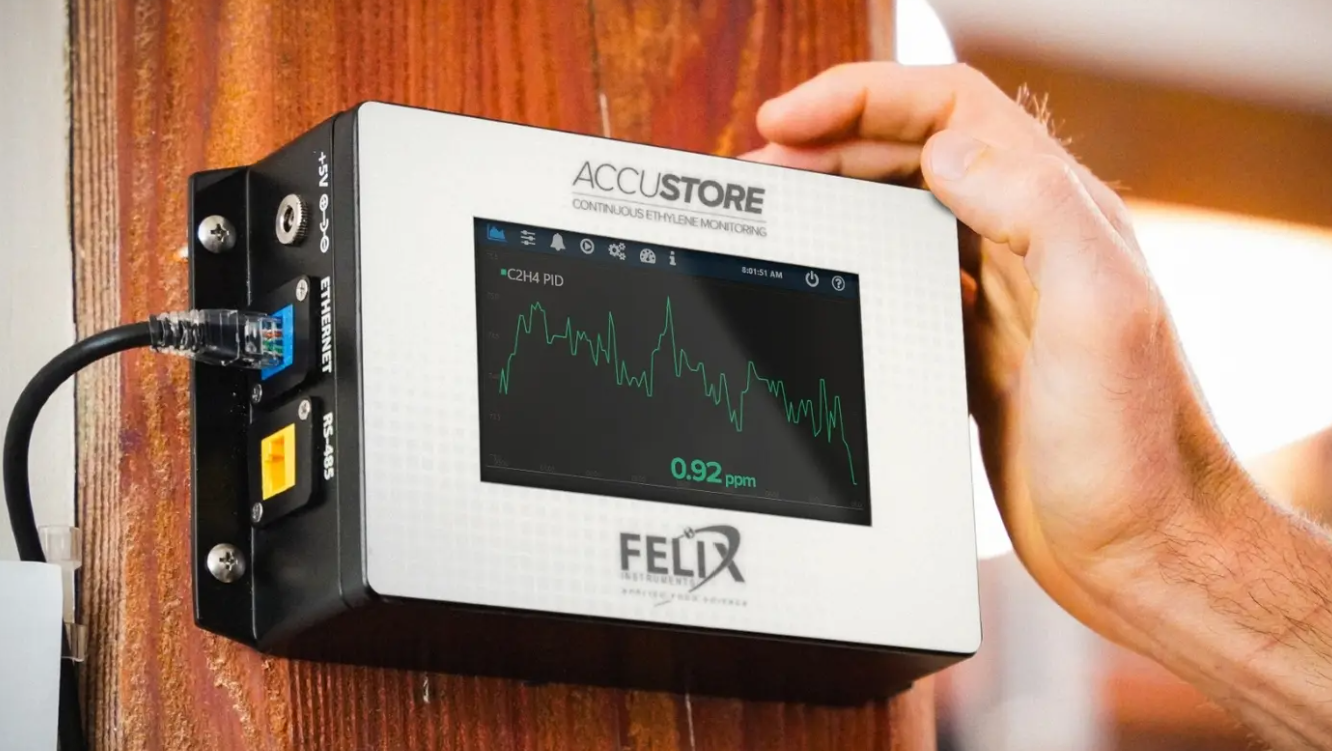

A group of scientists who were developing the optimum method of ventilation had to monitor gas exchanges in an effort to provide a commercially attractive balance of power consumption and potato quality preservation. Using the Felix F-900 of FELIX INSTRUMENTS, they were able to make confident, data-driven reccomendations. Ventilation Can Control Ethylene Gas and Respiration in Controlled AtmospheresPotato (Solanum tuberosum L.) is the fourth most important food crop and a staple in many regions of the world. To make potatoes available year round, the tuber is stored in controlled atmosphere conditions. Temperatures higher than 20ºC can lead to increased respiration and transpiration, which causes potatoes to lose around 58% weight in an 8-10 month storage period. Temperature also triggers ethylene production, which can alter the chemical composition of potatoes and, in later storage periods, enhance the sprouting of the tubers. During the warm summer months in North America, refrigeration is necessary to keep temperatures low, so potatoes are stored in controlled atmosphere conditions. The closed rooms must have good ventilation to prevent the build-up of ethylene gas, carbon dioxide, and respiration heat, while maintaining the right relative humidity to prevent weight loss and sprouting. Usually, fans are used to ventilate the cold storage facilities. Three scientistsEmragia, Sathuvalli, and Jayantwanted to find the fan speed and duration of use that would ensure ideal ventilation in potatoes while using less power consumption, as there was little research on this topic. Proper ventilation could prevent ethylene production and microbial spoilage of potatoes. Challenge: Measuring Ethylene Gas Production and Respiration Rate Non-DestructivelyThe scientists experimented on Rio Grande Russet potatoes stored in plastic drums for two seasons. The stored potatoes were exposed to continuous and intermittent ventilation with fans operating at speeds of 52?cubic feet per minute (CFM), 13 CFM, and 0.6 CFM; these potatoes were compared to a control with zero ventilation. The weight of potato drums was taken at the start of the experiment and after three and six months. At this time, the firmness of the tubers, sprouting rate, ethylene production, and respiration rate were also recorded. The researchers also calculated power consumption for six months in each of the six treatments; see Figure 1. The scientists needed a tool that could take non-destructive measurements of ethylene, oxygen (O2), and carbon dioxide (CO2) so that no potatoes were sacrificed during the experiment, as the initial and end weight of the whole potato batch was important. Removing tubers three times would make a difference to the weight of the five-gallon drum used for experiments. Traditional flow and closed systems, which measure the oxygen used for respiration and carbon dioxide produced by respiration, are destructive. The closed system needs at least an hour and can affect the rate of respiration and ethylene production, while the flow system is difficult for low respiring fresh produce. There are a few non-destructive methods, such as the micro gas chromatography detectors, to measure both ethylene and carbon dioxide. However, these methods are sensitive to changes in the atmosphere that could occur during three repeat measurements. The optical gas detectors accuracy in measuring ethylene depends on the type of sensors used, and both instruments are expensive. As shown in Figure 1, to record gas exchanges for six treatments and replicates, the scientists needed a method that was accurate and simple to use, yet robust enough to be used in a wide range of environmental conditions. Solution: Felix F-900 Portable Ethylene Analyzer Measures Ethylene, O2, and CO2By choosing the F-900 Portable Ethylene Analyzer, the scientists found a tool that made non-destructive measurements of not only ethylene, but also O2 and CO2. They were able to overcome the problem of low volumes of gases associated with flow systems by using F-900, whose high resolution sensors could detect concentrations as little as 0.025 ppm (25 ppb). The scientists placed three tubers in a one-gallon jar after weighing them. The F-900 was connected to the jar to measure ethylene gas and respiration rate as the ratio of O2 and CO2. Three tests were conducted for each set of treatments at the three designated data collection times: at the start of the experiment and three and six months into the experiment.