Packaging , Processing , Services

Predictive Maintenance, will allow to improve the performance or speed of a machine in its day to day operation

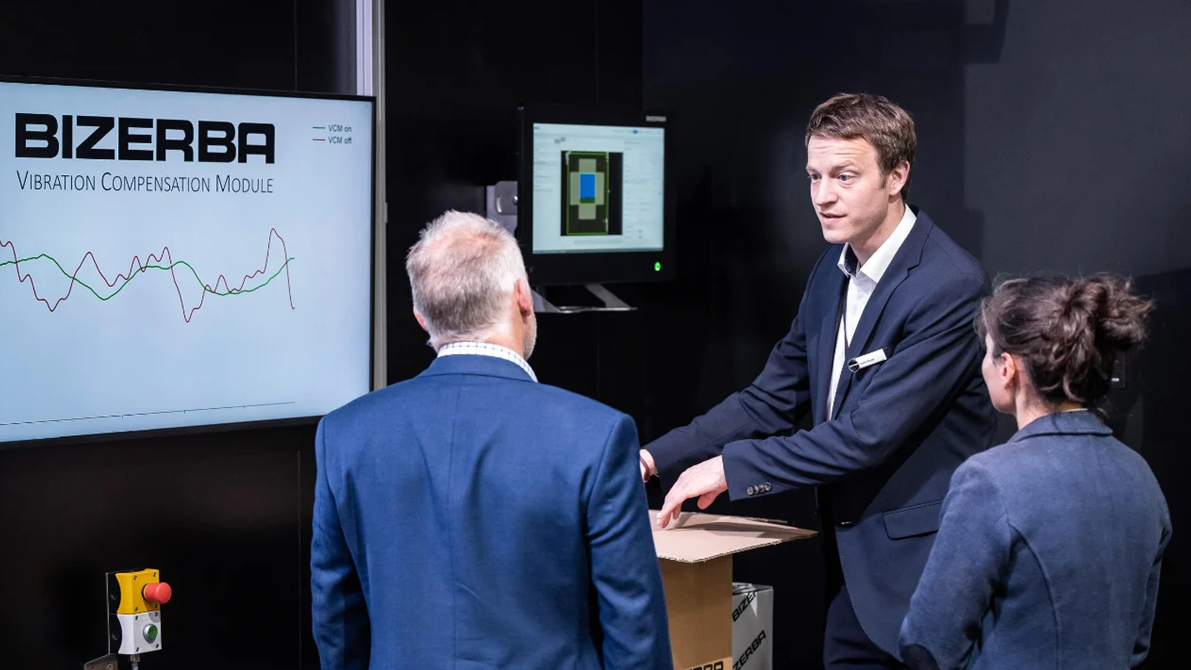

Cooperating with different partners and using multiple pilot projects in the area of labeling technology, Bizerba is testing the optimum use and seamless implementation of predictive maintenance in existing processes and systems. This is done to gain insight that enables predictive maintenance and therefore provides additional value to the company. In the future, predictive maintenance is supposed to improve the performance or speed of a machine in its day to day operation. Product quality is expected to improve thanks to an optimally adjusted machine, while availability is ensured by optimum maintenance. To reach this goal, the collected information must be relevant and meaningful. Sensors log operational data of machines on-site at the customer?s premises and forward them to a local computer using Bizerba?s BRAIN2 software. BRAIN2 collects and buffers the data before forwarding them to the Bizerba cloud for later analysis. Bizerba?s cloud platform can subsequently inspect the different parameters including start-up time or the

04 April, 2018

Cooperating with different partners and using multiple pilot projects in the area of labeling technology, Bizerba is testing the optimum use and seamless implementation of predictive maintenance in existing processes and systems. This is done to gain insight that enables predictive maintenance and therefore provides additional value to the company. In the future, predictive maintenance is supposed to improve the performance or speed of a machine in its day to day operation. Product quality is expected to improve thanks to an optimally adjusted machine, while availability is ensured by optimum maintenance. To reach this goal, the collected information must be relevant and meaningful. Sensors log operational data of machines on-site at the customers premises and forward them to a local computer using Bizerbas BRAIN2 software. BRAIN2 collects and buffers the data before forwarding them to the Bizerba cloud for later analysis. Bizerbas cloud platform can subsequently inspect the different parameters including start-up time or the overall runtime of the machines. Therefore, it is possible to track when the device is manufacturing and at which temperature it operates. If any deviations from the normal values should be detected during the inspection, a service ticket can be created to initiate immediate countermeasures which can be implemented by the machine itself, the installed software, a service technician, the customer or an alert on the Bizerba cloud platform. About BizerbaBizerba offers its customers in industry, trade, and logistics a globally unique solutions portfolio of hardware and software around the central value "weight". This portfolio includes products and solutions related to slicing, processing, weighing, cashing, checking, commissioning, filling and labelling. A wide range of services from consulting and service, labels and consumables to leasing complete the portfolio. Since 1866 Bizerba has made a significant contribution to the developments in the area of weighing technology and today is represented in 120 countries. The customer base includes globally operating companies in trade and industry as well as retailers, bakeries and butcheries. With 3,900 employees worldwide and with its headquarters in Balingen, Baden Wuerttemberg, Bizerba has been in the same family for five generations. As a globally operating technology company Bizerba is guided by the goal and commitment to achieve maximum results in terms of efficiency, hygiene and safety. Bizerba works every day to improve its products and solutions together with its customers and in the light of technological progress. The results are innovations, which become new standards. In order to meet this demand, Bizerba focuses on highest quality standards and globally valid technology standards in development and production. It is Bizerbas goal to provide users with products, which are easy to operate, and optimized for individual applications. In this way Bizerba supports its customers in the best possible way to ensure highest efficiency and effectiveness. Production facilities are located in Germany, Austria, Switzerland, Italy, France, Spain, China, Canada and USA. Bizerba also has a global network of sales and service locations. Source

https://youtu.be/qnQ8Xw_0Yc8