Packaging

Research focused on sustainable packaging

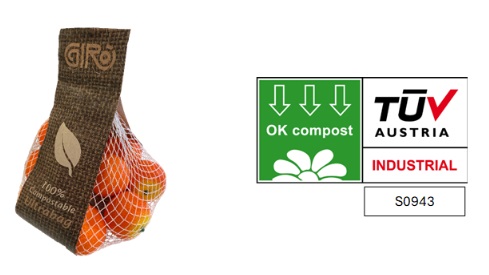

Franco Locati, sales manager of Girò Italia (in the picture): "Our qualified R&D team is focusing a lot on research, in order to improve the consumables in terms of environmental sustainability". "With regard to innovation, our goal is to develop new packaging systems involving sustainable technology and materials to produce resistant and 100% recyclable mesh bags. At the moment, our products involve materials whose minimum weight is between 3 and 12 grams, and that can contain up to 5 kg of fruit ". Girò is a multinational group based in Spain that works in 50 countries on 5 continents. It is recognized worldwide as a leading company in the production of packaging machines and consumables (mesh and printed films) suitable for producing bags for fruit and vegetables, providing great service and quality. In terms of sustainability, the company is focusing on reducing "emissions" in its offices and production centres. Locati: "The versatility of our machines allows the production of different types of packaging, to meet all the needs of the market. The biggest large-scale distributors rely on our packaging systems, where we market 2.5 billion packs a year. The core business of the company is the production and distribution of woven mesh for fruit and vegetable packaging, and the production of printed films and machines used for our products ". About a year ago, Girò inaugurated its first Italian headquarters in Milan. The branch will cover the Italian territory, in particular, the continental zone and the area of Sicily, for the important citrus production. Approximately 1.5 billion meters of printed band and 1.2 billion labels are produced annually in the two printing factories of the company. The production of machinery for packaging and weighing completes the packaging system. The pieces of machinery include: heat sealing packaging machines, netting machines, weighers, weight control and automatic canning systems. The brand counts a total of over 8000 packaging machines and 2000 weighers, and can offer multifunctional services on the market (one machine can produce 10 different packagings) together with the optimization of resources.

07 January, 2019

Franco Locati, sales manager of GIRÒ Italia: "Our qualified R&D team is focusing a lot on research, in order to improve the consumables in terms of environmental sustainability". "With regard to innovation, our goal is to develop new packaging systems involving sustainable technology and materials to produce resistant and 100% recyclable mesh bags. At the moment, our products involve materials whose minimum weight is between 3 and 12 grams, and that can contain up to 5 kg of fruit". Girò is a multinational group based in Spain that works in 50 countries on 5 continents. It is recognized worldwide as a leading company in the production of packaging machines and consumables (mesh and printed films) suitable for producing bags for fruit and vegetables, providing great service and quality. In terms of sustainability, the company is focusing on reducing "emissions" in its offices and production centres. Locati: "The versatility of our machines allows the production of different types of packaging, to meet all the needs of the market. The biggest large-scale distributors rely on our packaging systems, where we market 2.5 billion packs a year. The core business of the company is the production and distribution of woven mesh for fruit and vegetable packaging, and the production of printed films and machines used for our products". About a year ago, Girò inaugurated its first Italian headquarters in Milan. The branch will cover the Italian territory, in particular, the continental zone and the area of Sicily, for the important citrus production. Approximately 1.5 billion meters of printed band and 1.2 billion labels are produced annually in the two printing factories of the company. The production of machinery for packaging and weighing completes the packaging system. The pieces of machinery include: heat sealing packaging machines, netting machines, weighers, weight control and automatic canning systems. The brand counts a total of over 8000 packaging machines and 2000 weighers, and can offer multifunctional services on the market (one machine can produce 10 different packagings) together with the optimization of resources.

.jpg)