Paclife

Packaging

Packaging Solutions to Combat Pitting and Preserve Cherry Quality

The 2024 season is set to bring a 59% increase in cherry production in Chile, presenting both opportunities and challenges for the industry. Pitting, one of the biggest issues, requires solutions in both pre- and post-harvest stages, with packaging playing a crucial role. By Marcela Silva Acevedo, Agronomist - Postharvest Specialist at PacLife

.jpg)

This season’s significant increase in cherry production—59% more than estimated—will demand extensive efforts in both pre- and post-harvest to ensure high quality and condition despite overproduction.

Challenges of High Crop Load: Pitting and Firmness Issues

High crop loads lead to smaller sizes and softer fruits, making cherries more susceptible to mechanical damage like pitting. Pre-harvest practices, such as pruning and thinning, especially early thinning, are key to ensuring uniform harvests and high fruit quality. Late-stage chemical treatments can also be applied post-harvest to strengthen the fruit's skin.

Postharvest, careful handling is critical: transportation should be quick and gentle, using trays or dividers to reduce contact and pressure. Cherries must be kept at low temperatures with high humidity throughout the process, and careful management of processing lines is essential to prevent impacts on the fruit.

While varieties like Bing, Regina, Santina, and Lapins show resistance to pitting, all cherries are susceptible to some degree. Cherries have viscoelastic tissue, combining elasticity and plasticity, which allows them to recover from deformation—but not always completely. For instance, the Sweetheart variety is resistant but prone to deformation, making it sensitive to pitting. Lapins, the most widely grown variety in Chile, shares these characteristics. Studies with exporters have focused on the role of packaging in maintaining cherry quality during export.

Packaging as an Ally for Preservation

PacLife utilizes polymers like low-density polyethylene (LDPE) and biaxially oriented polypropylene (BOPP), which provide low to medium water vapor permeability. These materials reduce weight loss and maintain fruit firmness. Seasonal studies have shown that these polymers limit dehydration to less than 1% across various export species. In the 2023-24 season, blueberries showed a dehydration rate of 0.0–0.1% after 90 days, while cherries lost only 0.3–0.5% after 45 days. These results demonstrate a direct link between dehydration and pitting, highlighting the importance of secure packaging for preserving fruit condition.

A study conducted during the 2023-24 season with Lapins cherries showed clear differences between polymers. Packaging made with polyamides, nylon, or polyolefin blends allowed 3–90% higher water vapor permeability compared to LDPE or BOPP. This increased water loss led to greater susceptibility to pitting.

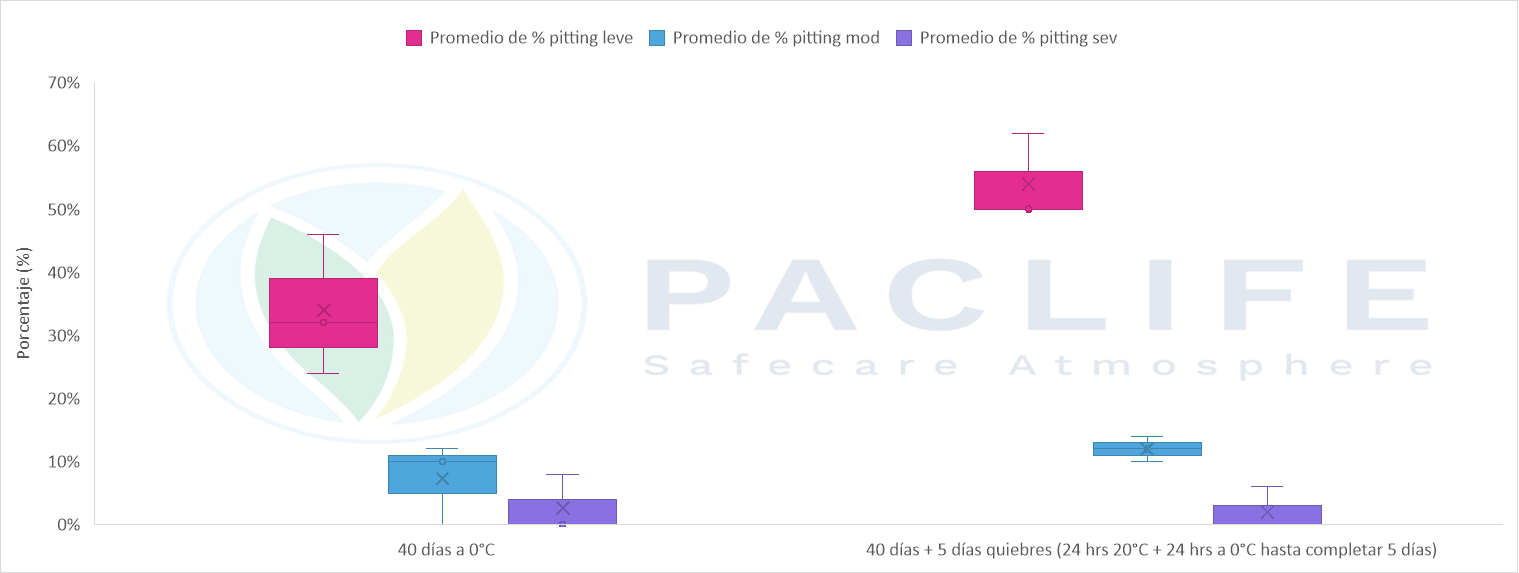

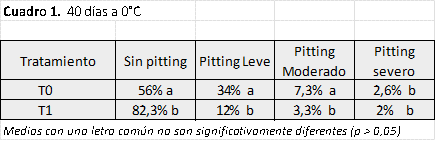

Figure 1: Pitting defect percentage for polyolefin/nylon-based packaging (40 days at 0°C, followed by 5 days of temperature fluctuation).

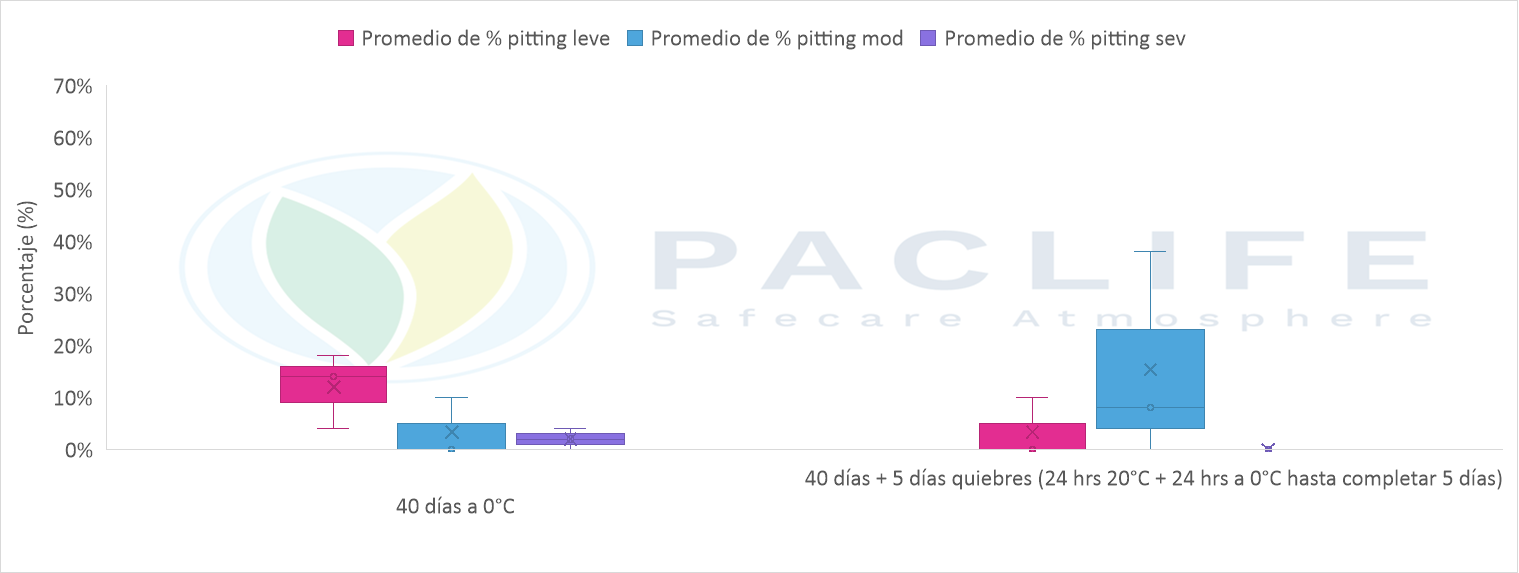

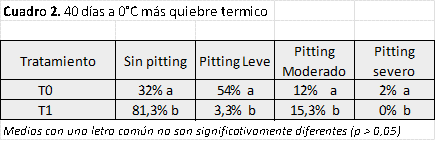

Figure 2: Pitting defect percentage for PacLife’s BOPP packaging under the same conditions.

Tables 1 and 2: Statistical analysis using Fisher’s LSD test (p≤0.05).

Virgin materials like polyethylene and polypropylene have lower water vapor permeability, helping maintain internal humidity. PacLife's solutions consistently limit dehydration to below 1%, reducing pitting risks.

A Path to Sustainability and Quality

Pitting is a significant challenge for the cherry industry, particularly for the Chinese market, which demands top-quality fruit. Effective strategies at each stage are crucial to reducing risks and maintaining fruit condition, ensuring high commercial value. Additionally, sustainability is increasingly important. Many industry players are adopting greener practices, and PacLife’s recyclable virgin materials provide a responsible, effective option for the export sector.