Phytosanitaries

Researchers from IVIA Highlight the Benefits of Applying Commercial Coatings in the Postharvest of Citrus Fruits

Coatings extend the shelf life of citrus fruits, improve their quality, and allow for energy savings during transport, boosting competitiveness in international markets

Redaccion

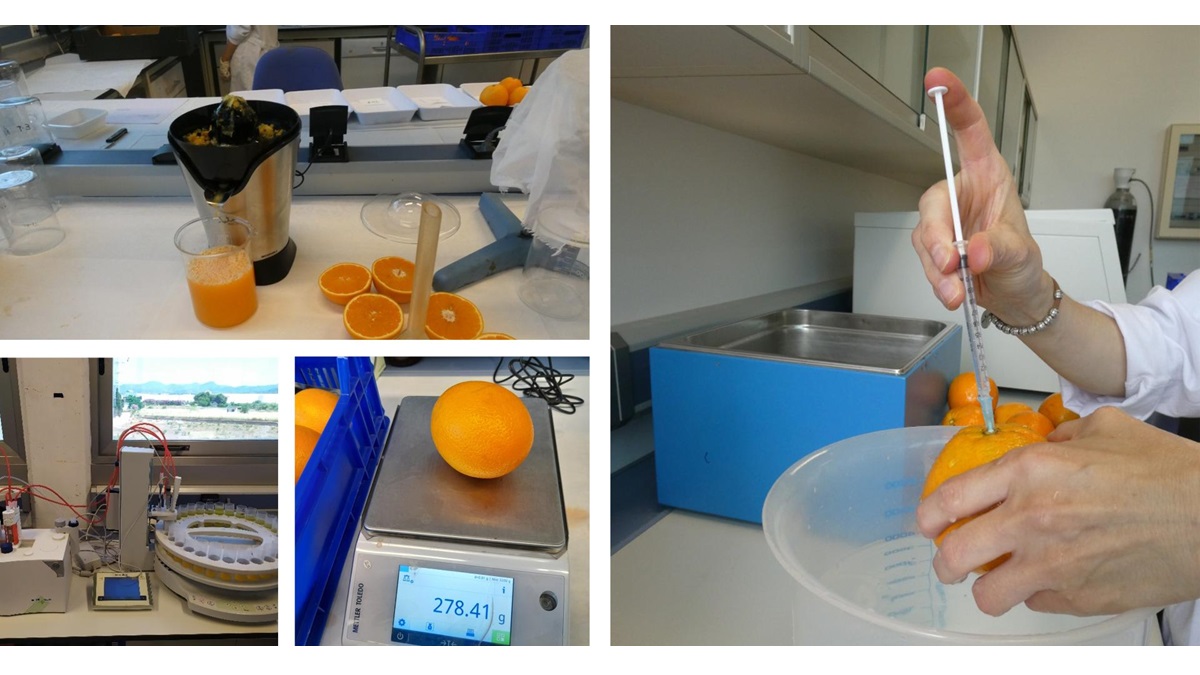

Dr. María Bernardita Pérez-Gago, a researcher at the Postharvest Technology Center (CTP) of IVIA, and Prof. Lluís Palou, Coordinator of the CTP, have led a research project that demonstrates the undeniable benefits associated with the application of commercial coatings in the postharvest of citrus fruits. The trials were conducted on a semi-commercial scale at the pilot plant and laboratories of the CTP with three commercial coatings developed by companies that are members of the Postharvest Cluster A.I.E.

The overall objective of the study was to evaluate the ability of the coatings to extend the postharvest life of citrus fruits for fresh consumption, both at ambient temperature and during cold storage, as well as to establish the potential energy savings in the transport of citrus fruits resulting from the use of coatings compared to uncoated fruit. To this end, oranges of the ‘Lanelate’ variety were used, and the physicochemical and sensory quality of the coated fruit was determined in comparison to the control uncoated fruit after the various postharvest storage scenarios considered:

- 30 days of cold storage at 1 ºC and 90% RH followed by 7 days of shelf life at 20 ºC,

- 15 days at 20 ºC and 70% RH, and

- 12 days at 8 ºC and 90% RH for the coated fruit, and 5 ºC and 90% RH for the uncoated fruit (simulations of transport conditions).

The following quality attributes were determined: weight loss (%), firmness (% deformation), skin color (Color Index, CI = 1000a / Lb), instrumental gloss (G.U., 'gloss units'), juice yield (%), juice quality [soluble solids content (SSC, °Brix), pH, titratable acidity (TA, % citric acid), and maturity index (SSC/TA)], external physiological disorders (cold damage, "pitting," skin collapse, etc.), incidence of decay (natural infection), internal atmosphere (% CO2 and O2 inside the fruit), volatiles (ethanol and acetaldehyde content in juice, mg/L), and sensory quality (overall flavor, off-flavors, external visual appearance, and ranking by gloss).

The results clearly showed the effectiveness of the three tested coatings in reducing weight loss and firmness, regulating gas and water vapor exchange, and providing shine to the coated oranges, both during ambient temperature storage and cold storage, without negatively affecting the other instrumental and sensory quality attributes. Furthermore, it was confirmed that these coatings could be used to transport oranges to export markets at a temperature higher than commercially established, potentially leading to energy savings in transport for citrus marketers.

In general, the results obtained with ‘Lanelate’ oranges are applicable to any commercially marketed variety of fresh citrus, and it can be stated that the different tested coatings contribute to the effective maintenance of the postharvest quality of citrus fruits, allowing for a longer shelf life and extended periods of storage and marketing. This could lead to better positioning in export markets and even the opening of new, more demanding markets, thus significantly improving the competitiveness of the sector.

The report on the results obtained in this study can be consulted in the IVIA repository (https://hdl.handle.net/20.500.11939/8933).