PND

Processing

PND Celebrates 25 Years at Fruit Logistica 2025 with Processing Solutions for All Business Scales

Showcasing Advanced Fruit Processing Solutions for Businesses of All Sizes, PND Continues to Set the Standard for Efficiency and Reliability in the Industry

PND marked its 25th anniversary at the Fruit Logistica 2025 trade fair, proudly showcasing its cutting-edge fruit processing solutions. With a long-standing history of innovation and success, PND has set the standard for efficiency and reliability in the fruit processing machinery industry. Today, its products cater to businesses of all sizes, from small startups to large-scale companies.

Virginia Cascella, Marketing Manager at PND, explained:

"We are thrilled to celebrate 25 years of success at Fruit Logistica 2025, alongside our incredible team and all those who have made this journey possible! What started as a small startup has blossomed into a leading company in the fruit processing machinery industry. We’re immensely proud of our accomplishments, and today, PND’s solutions are trusted by businesses in over 60 countries worldwide."

This year at Fruit Logistica, PND highlighted its advanced fruit processing technologies, which have made a significant impact in markets around the globe. Below are some of the standout machines featured at the event.

Solutions for Pineapple Processing

At Fruit Logistica 2025, PND unveiled two innovative pineapple processing solutions designed to meet the diverse needs of businesses in the fresh-cut fruit industry. These solutions cater to both small and large-scale operations.

MPC Model – Manual Pineapple Processing

The MPC model is a compact, countertop machine ideal for small businesses. It’s designed to slice, wedge, and chunk pineapples with precision. Featuring two sets of blades—one for slicing and another for cutting wedges—this machine is efficient and versatile. When used together, these blades effortlessly create chunks, making the MPC perfect for businesses entering the fresh-cut fruit market. Its easy operation, simple sanitation, and minimal maintenance requirements make it an ideal entry-level solution.

APC Model – Automatic Pineapple Processing

In contrast, the APC model is a fully automated system designed for larger companies that require high-volume production. Tailored for businesses supplying processed fruits to supermarkets and large retailers, the APC offers enhanced efficiency, high throughput, and user-friendly operation. Both the MPC and APC machines are built for reliability, with minimal downtime and an emphasis on sanitation.

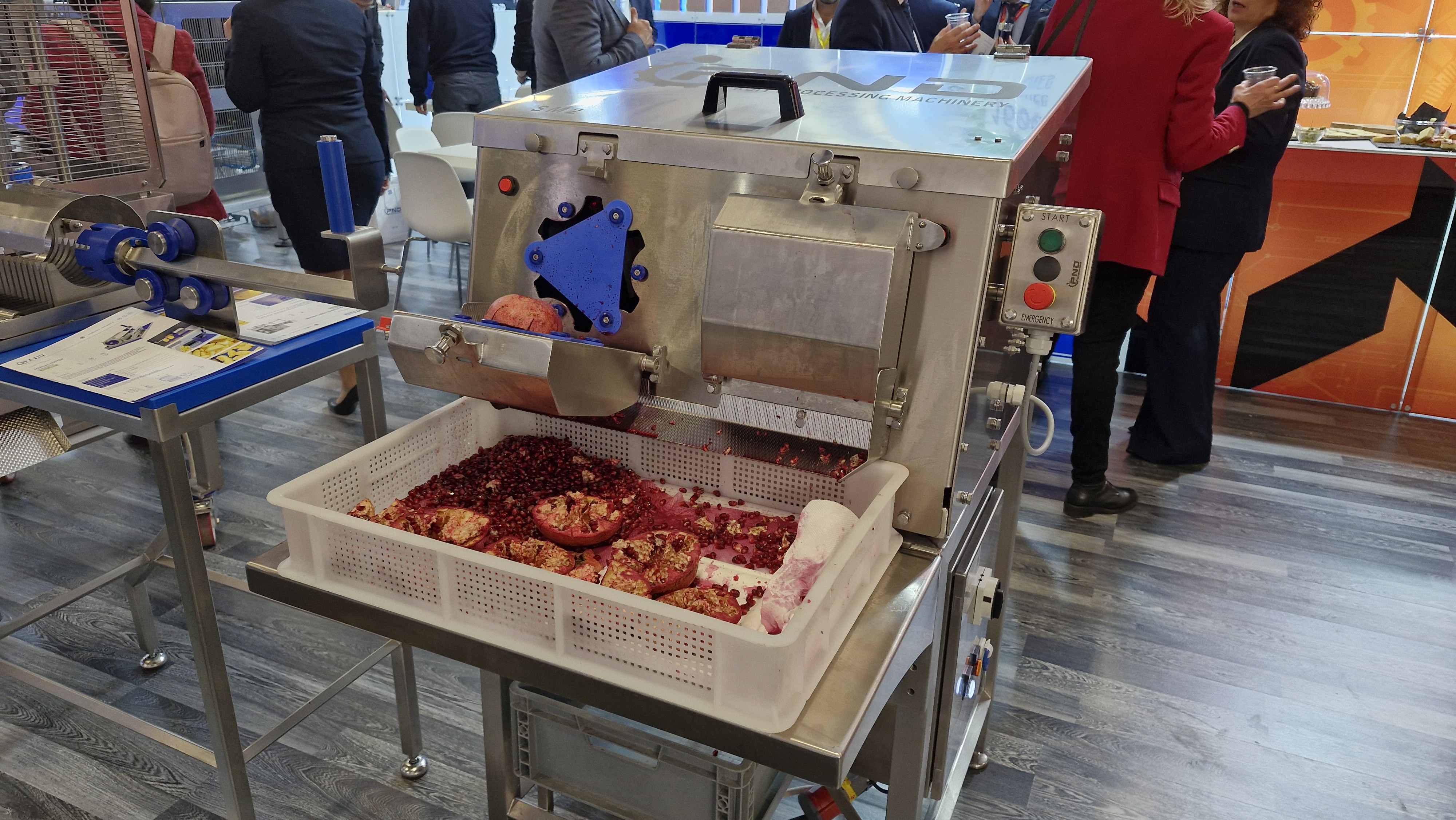

Solutions for Pomegranate Shelling

PND’s SM2 machine revolutionizes pomegranate shelling by maximizing efficiency while maintaining the fruit’s integrity. The process begins with manually cutting the pomegranate in half, followed by placing the fruit into the two processing heads. A mechanical system uses a lever to intermittently strike the fruit, helping to detach the kernels from the peel.

Built with a stainless steel frame, the SM2 machine features easy-to-replace components, and all parts in contact with the fruit are made from food-safe materials. Designed for fast cleaning and maintenance, it complies with the 2006/42/EC safety standards, ensuring a hygienic processing environment.

Solutions for Peeling Mangoes and Kiwifruit

PND's PL4M series of peeling machines are specifically designed for mango and kiwi fruit. Constructed entirely from stainless steel and food-grade materials, these machines accommodate fruits of various shapes and sizes. The advanced peeling system ensures maximum product yield, while the adjustable electric motors and pneumatic systems allow operators to fine-tune the process for optimal results.

With a production capacity of 44–56 fruits per minute, the PL4M machines are efficient and easy to operate. They require only manual loading and offer easy maintenance, with readily available consumables and spare parts.

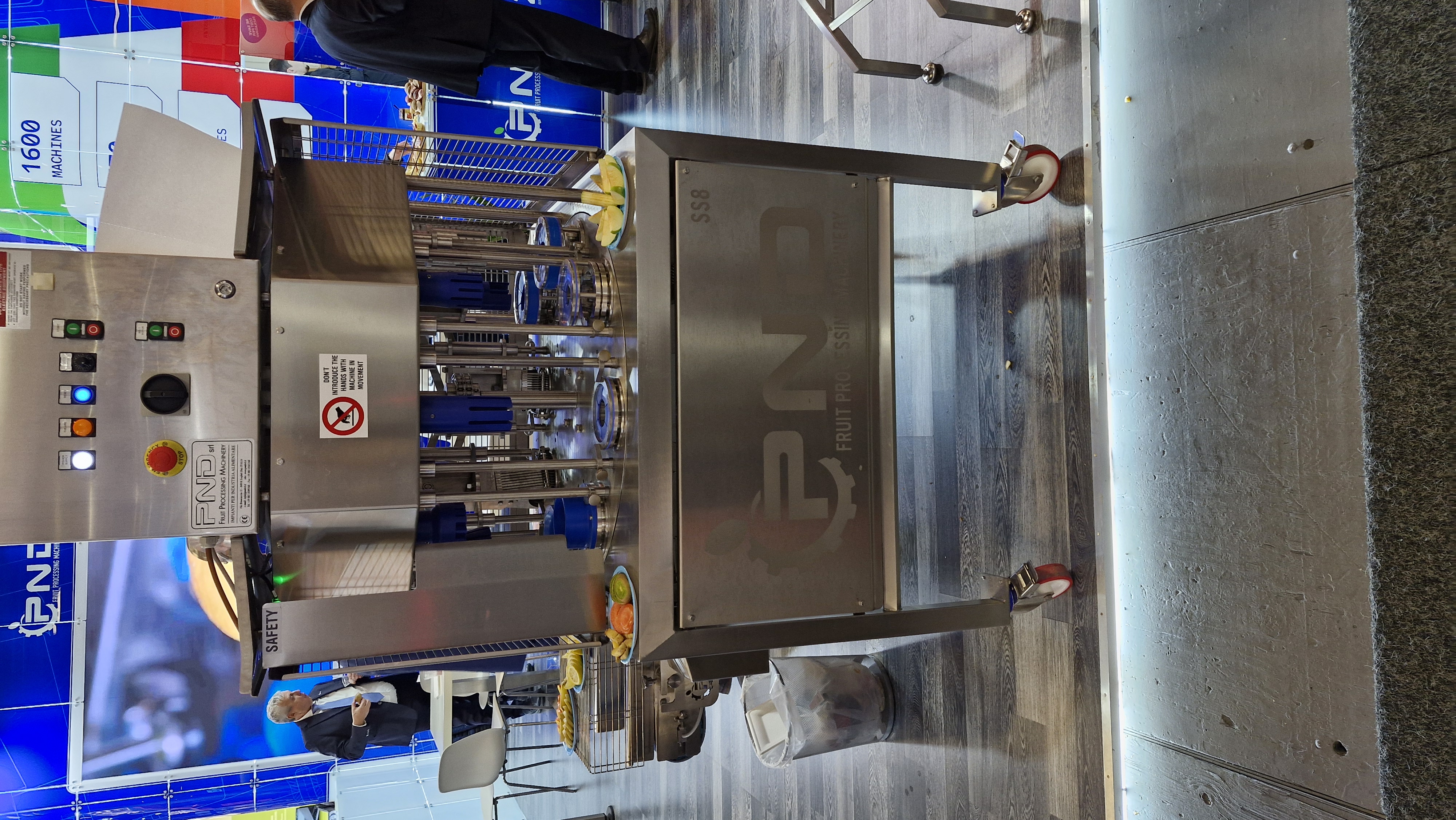

SS8 – Universal Cutting Machine for Fruits and Vegetables

The SS8 is a versatile, semi-automatic cutting machine capable of segmenting and coring various fruits and vegetables, including apples, pears, kiwis, pineapples, melons, and tomatoes. It produces slices, wedges, and sticks, offering flexibility in cut shapes and sizes. The machine operates by manually loading the fruit, which is then pushed through cutters by plungers, with the processed product collected on a conveyor belt.

With a production capacity of 40–50 fruits per minute, the SS8 is known for its robust construction, ease of maintenance, and compact design, making it easy to integrate into existing production lines. It complies with EEC/IP 65 food safety regulations and offers customizable cutting options, along with the optional feature of self-locking rotating wheels for enhanced mobility.

Looking Ahead: Future Exhibitions at Propak Africa and Propak Asia

As PND continues to expand its global presence, the company is preparing for upcoming exhibitions at Propak Africa in Johannesburg and Propak Asia in Vietnam. These events provide PND with exciting opportunities to connect with industry leaders, showcase new innovations, and strengthen its customer relationships worldwide.

As PND celebrates 25 years of success, the company is poised for continued growth, innovation, and leadership in the fruit processing machinery industry. With a commitment to quality and customer satisfaction, PND is excited for the many years ahead, shaping the future of fruit processing worldwide.