Actualidad

The 12th International Blueberry Conference connects blueberry growers and fans

About blueberry plantations and Bruno G. Defilippi, Chilenean researcher, analyzing post-harvest quality management

The 12th International Blueberry Conference 2024 is already in the books. The two-day event, considered the most important for the blueberry industry, gathered over 550 participants from 17 countries around the world.

That created great opportunities not only to deepen knowledge in the field of blueberry cultivation, but also to many important conversations, discussions and trade agreements.

Blueberry experts analyzing the main issues of the industry

Productivity of blueberry plantations

The first day of the Blueberry Conference took place at the Mazurkas Hotel in Ozarow Mazowiecki. 16 lectures were prepared for the participants, including one very important debate - 10 tons per hectare is no longer enough.

During discussion, experts showed how to improve production efficiency to obtain yields exceeding 10 t/ha. The debate was moderated by Dominika Kozarzewska from Polskie Jagody and the Core Team. Plantation productivity of 10 tons per hectare today is the minimum to be able to harvest and have investment opportunities - emphasized Andrzej Trela, a blueberry grower and member of Polish Blueberry Growers Association.

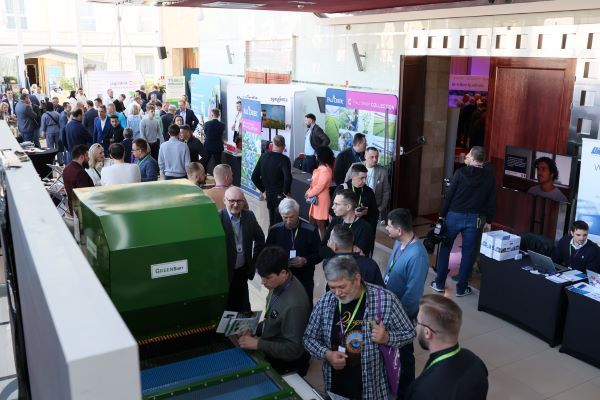

Companies with field and postharvest solutions exhibit in the Conference

From the new plantations that we established a few years ago, we obtain 20 t/ha for Draper and 25 t/ha for Liberty. This is only possible if the plantation was started with god nursery material and the site has been perfectly prepared - emphasized Leon Schrijnwerkers, a nurseryman and blueberry grower from the Netherlands.

Yield determines the profitability of production, but the second key factor is quality. It is the quality that is needed to increase the consumption of blueberries and encourage consumers to eat them regularly - concluded Krzysztof Żabówka, representing Fall Creek.

Important agrotechnical issues for blueberries

Prepared series of lectures concerned both topics related to plantation agrotechnics and market issues.

Dr. David Bryla (Oregon State University) from the USA presented results of two interesting experiments. The first one concerned management of soil pH on organic plantations. It turns out that in addition to using traditional methods, such as sulfur fertilizers, American growers use the so-called sulfur burners.

They work by burning sulfur and injecting sulfuric acid into the medium. It is the acidification of the nutrient solution and water used to irrigate the plantation that allows you to control the soil acidity and provide the best conditions for the growth of blueberry plants.

Research results regarding the possibility of reducing thermal stress associated with increasingly higher temperatures during fruit ripening and harvesting turned out to be equally interesting.

It turns out that the critical temperature for blueberry fruit is 32.2C. Above this value, fruit may be damaged and their quality (post-harvest durability) may be reduced. The research assessed effects of cooling by sprinklers operating at different time intervals.

Cyclical cooling of the fruit by sprinkling them gave the intended effect and helped avoid deterioration of the fruit quality. In case of some varieties, sprinkling also had a positive effect on the weight and firmness of blueberries.

What about blueberry pickers?

Wiesław Brzozowy, representative of Fieldstone Investments, gave his thoughts about hiring pickers and avoiding high staff fluctuation.

It is important not only to keep employees working on farms in a particular year, but also to encourage them to return for subsequent seasons. For employees, earnings is an important factor (how long they can work, whether the work is done on piecework), but also the plantation's surroundings motivates them to keep working and come back the next year.

The key role seems to be played by social conditions, organized places to spend free time, access to a well-equipped kitchen, etc. Nowadays, good Wi-Fi that that can be used "after work" is extremely important.

First of all, however, a very important issue is to prepare clear rules of work on a given plantation: what duties the employees have, what they have to pay for, what additional attractions they can take advantage of (e.g. dedication trips on days off).

Post-harvest quality management

The lecture by Bruno G. Defilippi from the Institute of Agricultural Research (INIA La Platina) in Chile turned out to be very interesting. The expert pointed out possibilities of storing fruit after harvesting and maintaining their quality during transport to target markets.

These are huge challenges, especially in the context of long-distance transport, which sometimes takes up to 30-40 days to reach distant markets. The key to success in this aspect is, above all, an appropriate harvest of fruit which is at the right stage of ripeness and is not exposed to pathogenic factors.

Currently available modified or controlled atmosphere technologies make it possible to stop life reactions and thus maintain fruit quality in the long term.

It is crucial to prevent water loss from the fruit in the first hours after harvest and to maintain the temperature range. Once the temperature is lowered, it should be maintained throughout the subsequent stages of fruit distribution.

Packinghouse machinery exhibiting in the Conference

Once again, it turned out that the Blueberry Conference unites people associated with the blue business. The room filled with listeners and the exhibition space buzzing with conversation confirmed that it was an opportunity both to gain knowledge and broaden horizons, but also to have important business talks.

60 companies took part in the exhibition part, many of which presented their products and solutions for the blueberry industry for the first time. Today we wish to invite you to the next edition of the International Blueberry Conference which will be held in 2025.

The Blueberry Conference team