Actualidad

A Comprehensive Guide to Best Practices for the Global Avocado Supply Chain

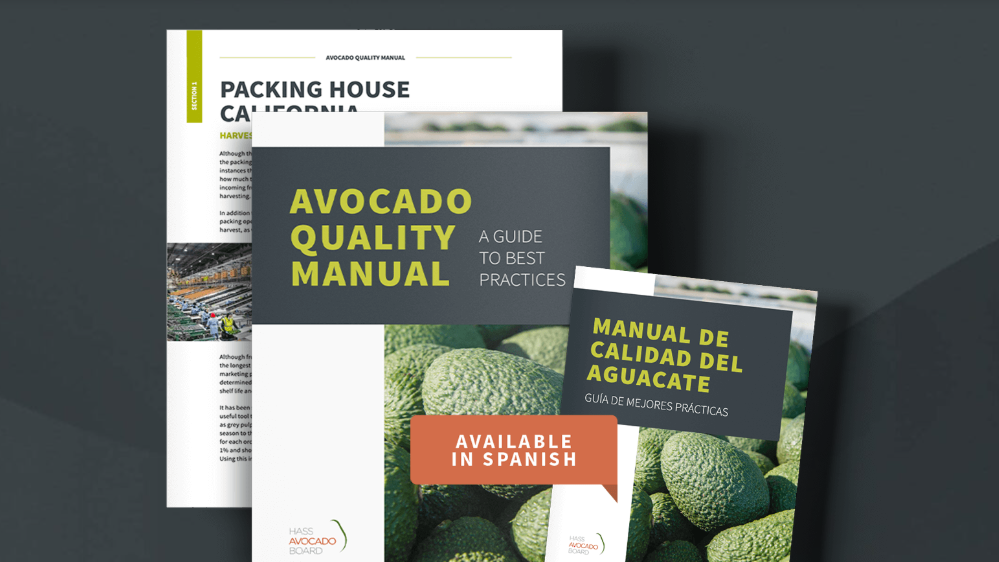

The newly expanded Avocado Quality Manual by the Hass Avocado Board now includes guidelines for Colombia, offering detailed best practices for the entire avocado supply chain, from farm to table, ensuring top-quality avocados across the globe

The Hass Avocado Board of the United States (HAB) has recently unveiled the latest edition of the Avocado Quality Manual, a critical resource that provides a comprehensive guide to best practices throughout the entire avocado supply chain. This updated edition now includes protocols for Colombia, further expanding the reach and importance of the manual within the global avocado industry. From the packing house to the final retailer, the manual offers invaluable insights for professionals aiming to ensure the highest quality avocados at every stage.

Key Updates in the New Edition

The updated Avocado Quality Manual now offers detailed protocols tailored to various aspects of the avocado supply chain, including:

-

Fruit Origin: Guidelines for sourcing avocados from different growing regions.

-

Maturity Level: Protocols for assessing and managing the maturity of avocados to ensure optimal quality.

-

Destination: Best practices specific to the geographical destination of the fruit.

-

Intended Sales Format: Instructions for handling avocados based on their sales format, whether they are intended for retail, foodservice, or wholesale.

This comprehensive approach ensures that operators worldwide have the necessary tools to maintain consistent avocado quality, regardless of where the fruit is sourced, where it's headed, or how it will be sold.

The Structure of the Avocado Quality Manual

The Avocado Quality Manual is divided into seven detailed sections, each focusing on a specific step in the avocado supply chain. These chapters cover everything from the initial harvesting and packing to the final retail display, helping industry professionals maintain high standards of quality throughout the process.

Section 1: Packing House – California

This section focuses on the best practices for packing avocados in California, the leading avocado-growing state in the U.S. It outlines processes such as:

-

Harvesting and Transport to the Packing House

-

Maturity Determination

-

Logistics Planning as Related to Dry Matter

-

The Pack Line

-

Fruit Cooling

-

Removal of Field Heat on Arrival at Packing House

-

Forced Air Cooling After Packing

-

Storage After Cooling

-

Ventilation of Cold Room and Cooling Tunnels

-

Packing House Cleaning

-

Transport Truck Loading

-

Administration of Quality Management at Packing House Level

Section 2: Packing Houses – Outside of California

This section is essential for producers and packers in other key avocado-growing regions, including:

-

Mexico

-

Peru

-

Chile

-

Colombia

Section 3: Transport

Efficient transportation is vital for preserving avocado quality. This section discusses optimal conditions for transporting avocados, including temperature control, moisture regulation, and handling protocols to minimize damage during transit.

Section 4: Distribution Centers

Once the fruit reaches distribution centers, handling protocols are essential to maintaining quality. This section provides guidance on storage, inventory management, and ensuring that the fruit remains in peak condition before being dispatched to retailers.

Section 5: Re-packers and Fruit Ripeners

For those involved in ripening or re-packing avocados, this section covers:

-

Unripened Re-packed Fruit

-

Ripened Fruit

-

5 Stages of Ripeness

Section 6: Retail Sales (Green and Ripened Fruit)

Retailers will find essential advice on managing the fruit in-store:

-

Ordering and Inventory Control

-

Storage of Fruit After Arrival

-

Fruit Display

-

Staff and Customer Education Section

Section 7: Common Fruit Defects

This section helps operators identify and address common issues that may arise during the avocado journey:

-

Fruit Softness

-

External Defects

-

Internal Defects

Why This Manual Matters

The new edition of the Avocado Quality Manual is an indispensable tool for professionals in the avocado industry. By including protocols from multiple countries, including Colombia, it offers a truly global perspective on avocado quality standards. Whether you are a grower, packer, distributor, or retailer, the manual provides step-by-step guidance to ensure that avocados meet the highest quality standards from the farm to the table.

Operators can now download the full guide or access individual chapters directly from the Hass Avocado Board’s website at hassavocadoboard.com/avocado-quality-manual. This easy-to-access format ensures that operators at every level of the supply chain can stay up to date with the latest best practices and industry standards.