TOMRA Food

Conditioning , Processing

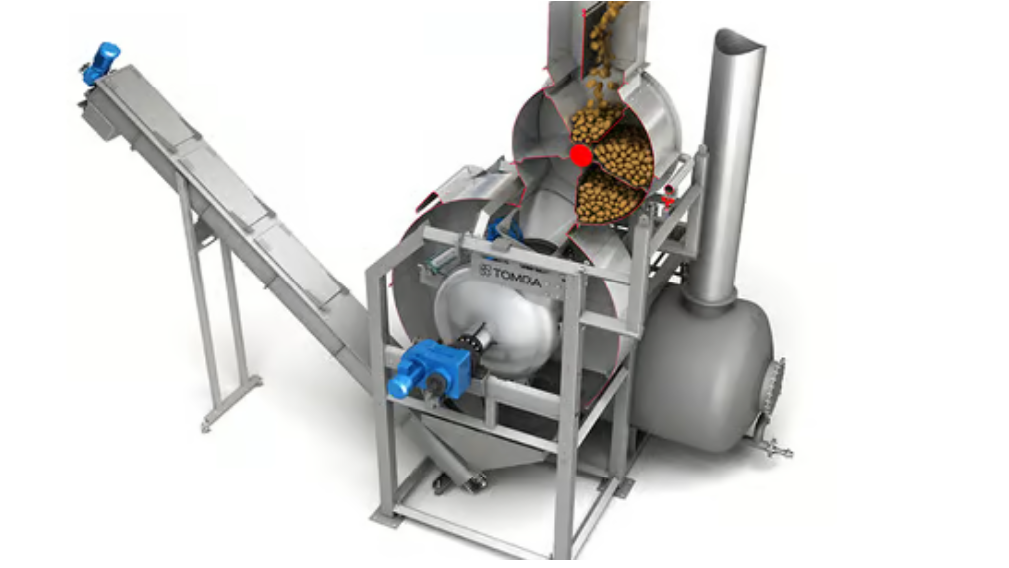

Eco steam peeler, using steam and going green

The Eco Steam Peeler leads the food processing industry in the pursuit of the highest peeling performance and reduced waste to enable processors to achieve sustainability objectives in their food production.

The TOMRA Eco technology uses sensors and algorithms to deliver optimised peeling performance by providing processors with an automated peeling process that is continously adjusted as the incoming quality of raw material varies - thus reducing energy use up to 25% and delivering the lowest peel loss available.

Speed and accuracy

Rapidly transferring heat from the pressurized steam to the surface of potatoes generates the highest yield, and here the Eco steam peeler holds the pole position.

Improved process control & shorter steam times

Drawn into the chamber in 1-2 seconds, steam is evenly distributed to every potato's surface with the help of our one-of-a-kind patented mixing system.

Fast in and fast out

Research shows that immediate steam evacuation stops cooking the potato and saves valuable product, so we invented a release valve that lowers exhaust times to 1 second.

Supersized savings

The Eco Steam Peeler dramatically improves process efficiency - saving €50,000 to €80,000 ($57,967 - $92,748) each year in costs.

Every piece is unique

The TOMRA Peeling Line automatically adapts to variations of incoming vegetables and the quality of the products without the need for operator intervention. Rapidly transferring heat from the pressurized steam to the surface of potatoes generates the highest yield, and the Eco Steam peeler holds the pole position.

Better process control &shorter steam times

Drawn into the chamber in 1 second, steam is evenly distributed to every potato's surface with the help of TOMRA unique patented mixing system for better process control and shorter steam times.

Using steam and going green

Our ECO technology replaces a fixed steam supply with a controlled steam management system - reducing energy waste by up to 25% and delivering the lowest peel loss available.