Urschel Laboratories

Processing

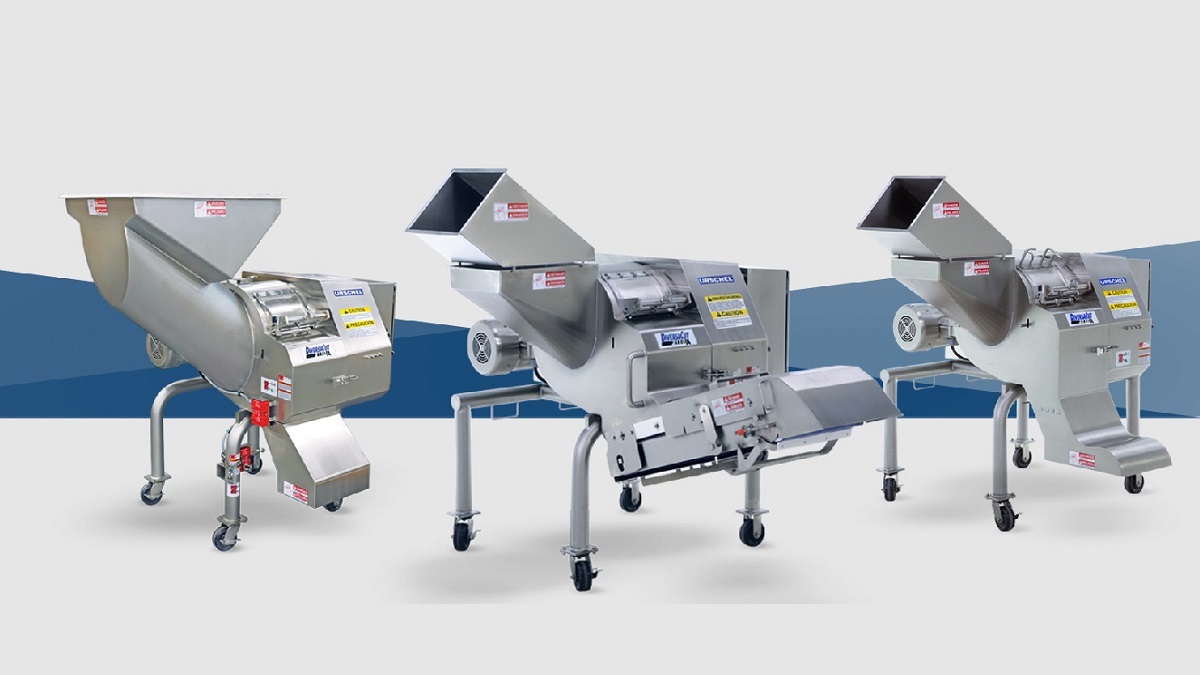

DiversaCut 2110A® Dicer, eliminates the need for pre-cutting the product

DiversaCut 2110A® Dicer (standard)

URSCHEL's DiversaCut 2110A cuber (above, right) accepts a maximum product feed of 10” (254 mm) in any dimension and saves costs by eliminating the need to pre-cut products. Its endless versatility goes beyond the food industry. It is primarily sold to reduce vegetables/fruits, bakery ingredients, dairy products to add, meat/poultry/seafood/pet food and alternative products.

This cuber can be equipped with either a 5 (3.7 kW) or 10 (7.5 kW) horsepower motor. The machine provides continuous operation for uninterrupted production and is designed for easy cleaning and maintenance. The cross-cut knife spindle, along with the other cutting components, creates a compact cutting zone that makes precision cuts as the product moves through the process.

NEW DiversaCut 2110A® Dicer with belt conveyor

The DiversaCut 2110A cuber with conveyor (above, center) offers a preconfigured approach to processors. It accepts a maximum product infeed of 10” (254 mm) in any dimension and offers savings by eliminating the need to pre-cut products. The built-in infeed conveyor ensures a successful transfer point to maximize product quality and improve yield. The infeed conveyor facilitates batch processing into bags, onto other infeed conveyor systems or onto pallets. The new machine also facilitates routine maintenance by keeping the machine at ground level.

The DiversaCut series offers endless versatility beyond the food industry. The DiversaCut models are sold primarily for reducing vegetables/fruits, bakery ingredients, dairy to add, meat/poultry/seafood/pet food and alternative vegetable products.

The cuber is equipped with a 5 HP (3.7 kW) motor and a 1/4 HP (.19 kW) feed belt motor. The machine provides continuous operation for uninterrupted production and is designed for easy cleaning and maintenance. The close proximity of each cutting station in relation to the next creates a compact cutting zone. This results in precision cuts as the product moves through the process.

DiversaCut 2110A® Dicer with large product infeed

Urschel offers a solution focused on processing whole heads of leafy vegetables: the DiversaCut 2110A® dicer specially equipped with a large feed hopper (above, left) and a new type of impeller. Working with leading fresh-cut processors, this new development alleviates pre-cutting and minimizes product handling.

This DiversaCut 2110A model with large product infeed (MDCA, LPI) accepts products up to 14” (356 mm) in diameter. This machine is available through our Certified Engineering Print program - a specialized service aimed at producing machines ideal for individual process lines/configurations. This machine is designed to interface with product pick-up devices.