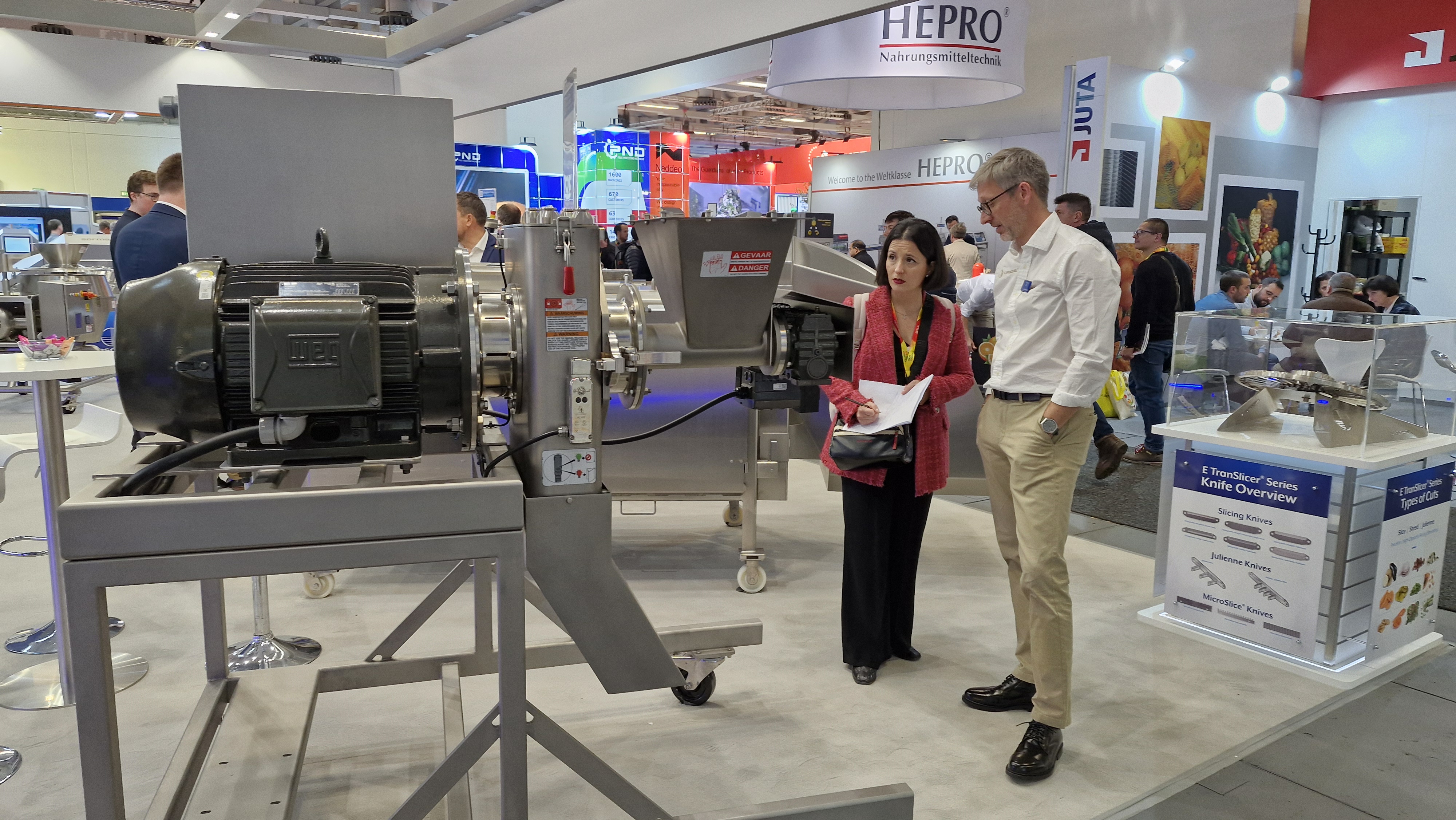

Comitrol Disc Mill 380 (DM380): Efficient Milling of Nuts & Seeds

Another standout innovation from URSCHEL is the Comitrol Disc Mill 380 (DM380), designed to excel in both small-batch and high-volume continuous production. This machine is specifically engineered for processing nuts and seeds, converting them into smooth pastes or butters. The adjustable disc configuration provides precise control over the final texture, allowing for everything from coarser products to ultra-fine finishes with exceptional consistency.

Key Features:

- Independent or pre-milling operation alongside a Comitrol Processor, delivering smooth and uniform products.

- Integrated hopper and variable-speed screw feeder enhance versatility and optimize the milling process.

- Compact structure with a foldable door for easy maintenance and cleaning, minimizing downtime.

- Built with sanitary stainless steel, ensuring long-lasting durability for continuous operation.

- Safety monitors and protective locks for secure operation.

The DM380 not only provides outstanding flexibility in terms of texture and volume but also excels in easy maintenance and advanced safety integration. Its performance, versatility, and safety make it an indispensable tool for optimizing nut butter and paste production.

URSCHEL: Driving Continuous Innovation in the Food Industry

URSCHEL’s participation in Fruit Logistica 2025 underscores its unwavering commitment to innovation and technological advancement in the food industry. By delivering personalized, highly efficient solutions, the company continues to establish itself as a leading authority in food size reduction and cutting technology. With over 50 years of experience, URSCHEL remains dedicated to continuous product improvement and offering close support to its clients, consistently staying at the forefront of the evolving needs of the global horticultural sector.