Wyma Solutions

Conditioning

"Fresh Thinking" for the Most Advanced Vegetable Processing Equipment

Visit to Wyma's Facilities in Christchurch, New Zealand, the Company's Headquarters Specializing in Equipment for Producers to Showcase Their Vegetables

In November, Postharvest 2024 took place in New Zealand, and one of the days following the event offered the opportunity to visit Wyma's facilities in Christchurch, on the South Island. Here, potato polishers and all the equipment for underground vegetable handling lines—Wyma’s specialty—are manufactured and equipment for fruits and vegetables. The company operates globally, and during our visit, they were also hosting their regular distributor meeting.

The Facilities

Wyma was founded in 1962, pioneering the introduction of locally manufactured machinery specifically designed to reduce handling by vegetable producers. Today, Wyma operates globally but continues to maintain the culture of addressing the needs of local producers at each location.

In 1991, the original company was acquired by engineer John Wyma, who developed a wide range of innovative and high-quality equipment. In May 2023, Wyma was acquired by MHM Automation, a company that, like Wyma, has its roots in Christchurch, established in 1884.

Wyma’s modern facilities are state-of-the-art, and the company also manufactures equipment in Europe. Together, these facilities support sales offices, projects, and after-sales service in the UK, Europe, North America, Australia, and New Zealand, as well as customers in regions including Canada, Colombia, Chile, South Africa, Egypt, Saudi Arabia, and Madagascar.

Equipment

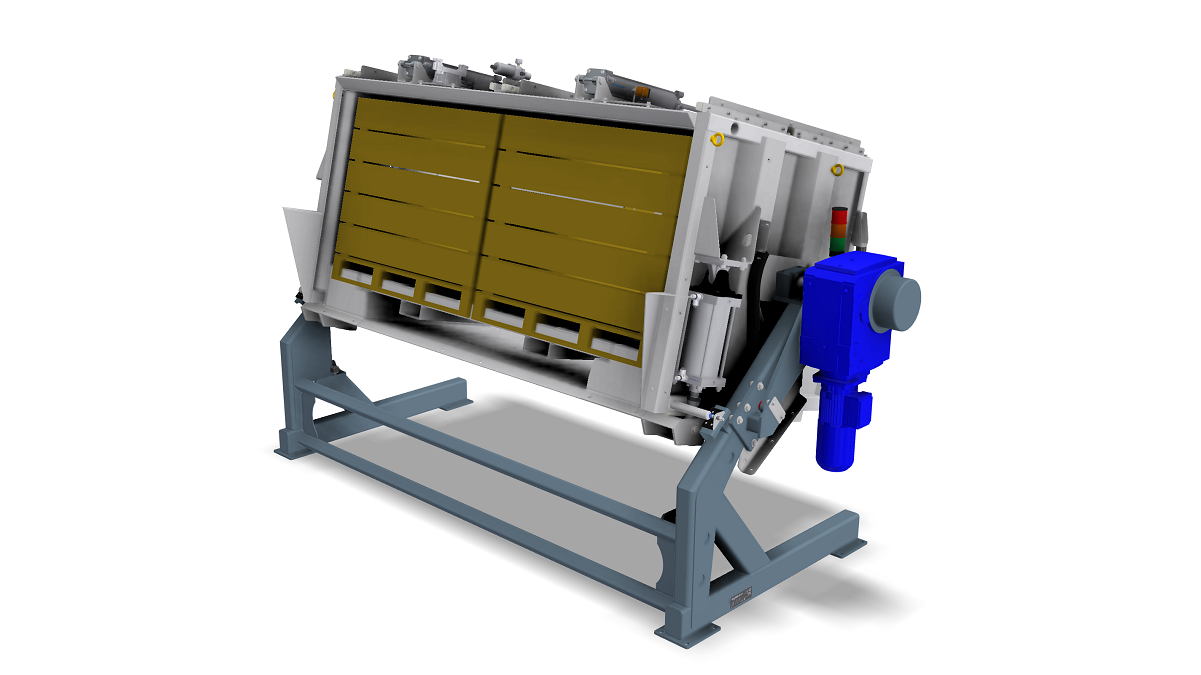

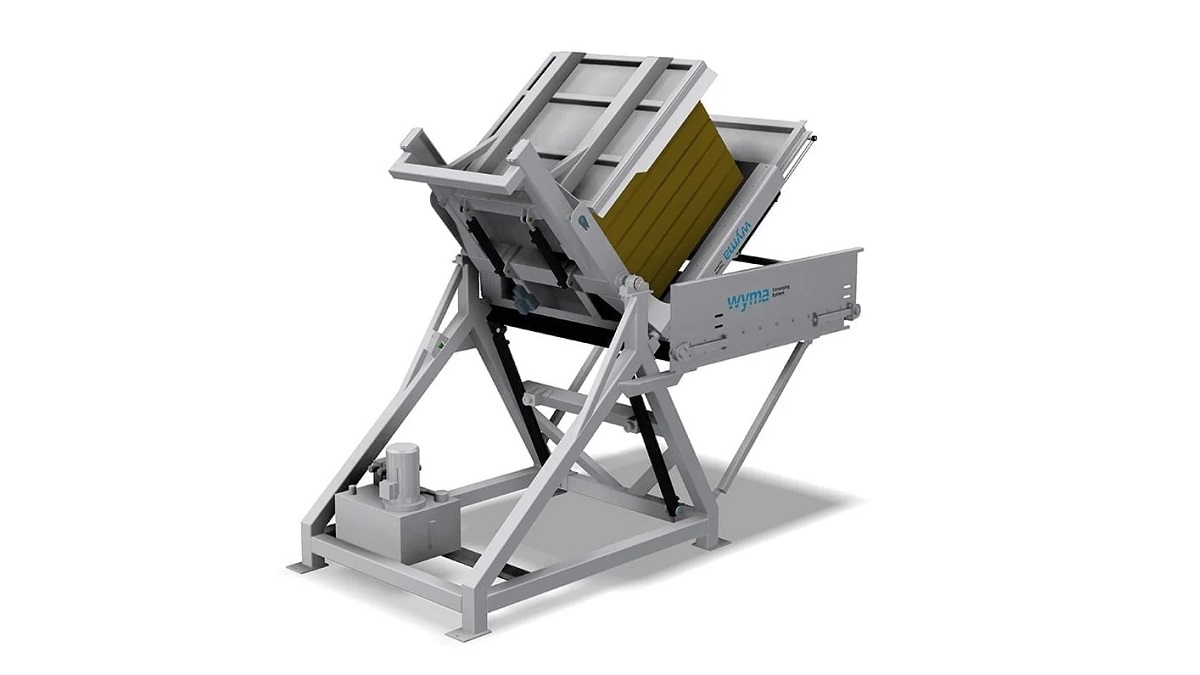

Wyma’s flagship product is the Vege-Polisher, a potato polisher, but this is just one of many products in their extensive portfolio. Each piece of equipment is designed to serve specific stages of the handling lines they install. All Wyma equipment is engineered for easy transportation in 20 or 40-foot containers. Their expertise lies in providing global packing line solutions, based on the latest automated industrial designs, with an emphasis on ease of operation.

The main goal of these machines is to improve how products are presented for sale, in supermarkets and to consumers, thereby maximizing profitability for producers. One of their latest innovations, the Optical Roto-Cut trimmer, introduces a significant advancement in vegetable processing technology. This fully automated optical trimming system removes foliage, crowns, and stems from vegetables before they are packed or processed.

Wyma’s equipment portfolio caters to the diverse needs of packing lines, tailored to different products and product characteristics (e.g., product volume). Their equipment is categorized into several key areas, including tipping, hoppers, stone removal, transportation systems, waste removal, brushing, washing, polishing, peeling, water recycling, cooling, drying, sizing, inspection, filling, and packing/palletizing.

From Manufacturing to Operation

Once the design is complete, Wyma's team of experts oversees every aspect of the process, including design, installation, commissioning, and ensuring compliance with health and safety standards. They also manage all necessary documentation and training.

The engineering department, consisting of 60 engineers, is responsible for designing both the handling plants and the equipment. The manufacturing process involves working with galvanized steel plates, which are painted, or stainless steel, which is punched and shaped on-site. Once each piece of equipment is manufactured, its functionality is tested before being disassembled and prepared for shipment to its final destination.

In the main image, Mike Coker, Senior Marketing Specialist, who guided us during the visit, and the author are pictured next to a Vege-Polisher vegetable polisher amid its manufacturing process.

The slogans that guide the company's work: CRISP and Fresh. The first term, CRISP, stands for Customer Centric, Reliable, Integrated, Stream-driven, and Proactive. It reflects the company's focus on being customer-centered, reliable, integrated, synchronized, and proactive. Fresh encourages creative thinking for solutions